Make sure to remove the MicroSD from the control board. Some SKRs with the CNC builds would have issues if you left a card in for some reason.

even if the card is empty? I’ll give that a shot after dinner.

Yeah, weird I know.

Not sure if the SD card had anything to do with it. I think the first firmware I tried to load was for the wrong board and it corrupted the bootloader.

Some combination of the following commands is what fixed it:

sudo dfu-util -d ,0483:df11 -R -a 0 -s 0x8000000:leave -D ./M8P_V2_H723_bootloader.bin

sudo dfu-util -a 0 -D ~/klipper/out/klipper.bin --dfuse-address 0x08000000:force:mass-erase -d 0483:df11

make flash FLASH_DEVICE=0483:df11

At one point I even ran this bastardization of the above commands

sudo dfu-util -d ,0483:df11 -R -a 0 -s 0x8000000:force:mass-erase-D ./M8P_V2_H723_bootloader.bin

I did take the SD card out. I’m too chicken to try to put it back and see if it still loads. I’ll play with the printer more tomorrow. I had a rough day of coding at work today and don’t really feel like screwing with config files anymore tonight.

Tomorrow night I’ll try to get the axis moving and get the probe working. I did test the two temp probes today by blowing a heat gun at them. The temperatures moved on the graph, so that’s working. Although I think I have the wrong thermistor type set for the heat bed.

Got up this morning and started going through the configuration checklist.

Tested out the two heaters, endstops, and stepper movement. That’s where I stopped for now. I need to setup the probe next before I can home. I also want to switch the bed over to PID. I just copied the config from biqu’s github and it had the bed heater set to waterfall.

Testing out the extruder heater had me worried… When I first told it to turn on, it failed. I forgot I hadn’t plugged the heater into the board yet ![]()

I did like how easy it was to configure the endstops. I went ahead and plugged in the z endstop even though I’ll be using the probe for z. That reminds me, I need to put the glass bed back on the heater.

I also need to figure out what type of thermistor I have on the heat bed. I didn’t update the config for that yet either.

Lastly, I need to extend the parts cooler fan wires and do some cable management on the printer.

Oh. And I need to find the filament stand I used to use with this printer. It’s one of the little simple ones where the roll sits on 4 bearings. Maybe I should print one of the holders that mounts to the top of the gantry frame.

So many little things to do before I can start melting plastic.

It all seems so simple then the more you think about it there are SO MANY little things that all have to happen too

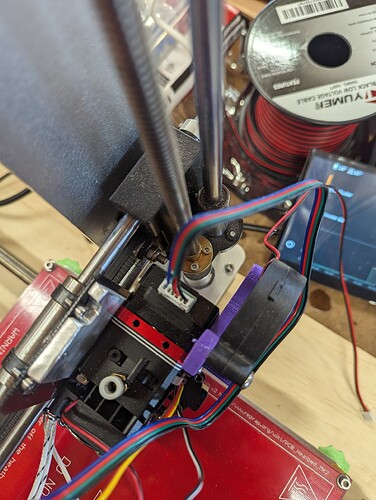

I forgot how small this printer is. And the new extruder is closer to the gantry, so there’s clearance issues.

With the new nozzle offset, it looks like I’ll have about a 90x90mm build plate.

I have ‘homing’ working with the normal z endstop. I was able to jog the steppers. This machine is pretty silent with the new stepper drivers.

I was at this point this weekend, I was actually considering going back to Marlin, then decided to turn everything off and walk away for now, LOL.

I was at that point last night. Not with Klipper but just the entire build process. I was somehow thinking it was going to be quick lol. Thinking about it in big chunks sounds a lot faster than when you break it down into all the little things LOL. Having to make myself just pick a part and work on that till its done before moving on to something else. About to start and finish the last of the aluminum parts, then on to the next task LOL

Let’s not forget that I also need to put new connectors on EVERYTHING. I’m just shoving the dupont connectors into all the spots, but I want to put the actual clip-in connectors on everything. I’m sure that will take a few minutes.

Oh. And I just remembered I wanted to setup a git repo for storing my configs…

LOL I just pull the plastic like we did on the SKRs and keep the duponts I’ve never one had one come off doing it that way

This older printer is a bed slinger. It’s been known to rattle connectors loose. The last controller I used I had a box printed that had strain relief to hold the wires in place.

I prefer the jsh-xt connectors to the dupont because they lock, but until recently my crimping skills were very much lacking, but now only slightly lacking, but improving. My v4 has the xt connectors which I prefer now. The mpcnc has rj45’s at the controller exit to dupont to the motors. With my z brake motor testing, I’ve spent a lot of time crimping connectors and gotten much better.

Only got 2 done before needing to leave for dinner.

Don’t forget kids… The spring pressure can be adjusted on your crimpers so you stop chopping the connectors off

![]()

Finished the night last night with the two endstops done and one stepper motor done. Spent most of my evening prepping for fiberglassing the kayak. It’s just the wife and I at the house tonight, so don’t expect much 3d printer progress.

OHHHHHH

She doesnt do Fiberglass, LMAO

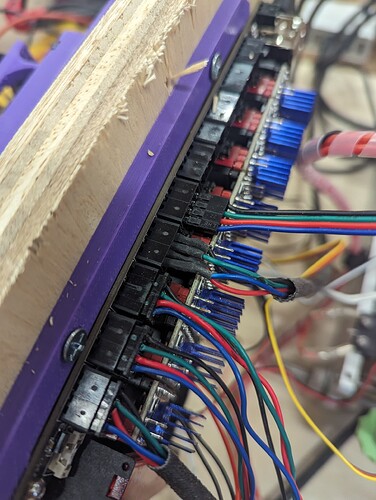

In case you were wondering how janky my connections have been in the past…

Check out this beaut.

Individually shrink wrapped pins.

I see nothing wrong here. It’s not stupid if it works lol