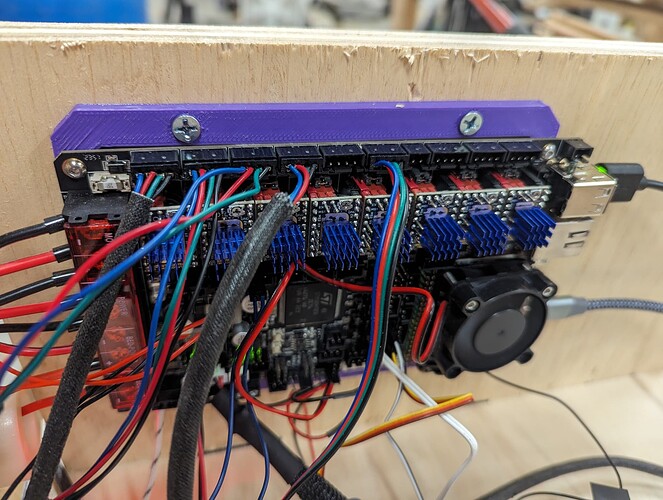

“Heat shrink is for rich kids.” - said no one ever

Contrast that with not individually shrink wrapped… lets say that might have happened once.

It pays to do a good job on the wiring both in headache and maintenance.

now add hot glue or silicon to avoid disconnects!

Ok. I have the connectors redone. Now I’m working on getting the machine to work.

The Biqu v2 probe I’m using is fighting me.

It’s throwing the following error when I try to do a G28 Z

10:36 AM

MCU ‘mcu’ shutdown: Can’t add signal that is already active

10:36 AM

MCU ‘mcu’ shutdown: Can’t add signal that is already active

Once the underlying issue is corrected, use the

“FIRMWARE_RESTART” command to reset the firmware, reload the

config, and restart the host software.

Printer is shutdown

10:36 AM

Homing failed due to printer shutdown

10:36 AM

Klipper state: Shutdown

10:36 AM

G28 Z

Here’s the code I’m using.

[output_pin probe_enable]

pin: PD12

value: 0

[gcode_macro Probe_Deploy]

gcode:

SET_PIN PIN=probe_enable VALUE=1

[gcode_macro Probe_Stow]

gcode:

SET_PIN PIN=probe_enable VALUE=0

[probe]

pin: ^!PD13 #For V1 version, set to ^PD13 for high-level trigger; for V2

#version, set to ^!PD13 for low-level trigger.

deactivate_on_each_sample: False

x_offset: 0.0 # Actual offset of the MicroProbe installation

y_offset: 0.0 # Actual offset of the MicroProbe installation

z_offset: 0.0 # Actual offset of the MicroProbe installation

speed: 5.0

activate_gcode:

Probe_Deploy

G4 P500 # Allow 500 milliseconds for the probe to deploy

deactivate_gcode:

Probe_Stow

And in my printer.cfg for z axis

[stepper_z]

step_pin: PB8

dir_pin: !PB7

enable_pin: !PE0

microsteps: 16

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop

position_max: 180

can you CTRL+F search/find PD12 and PD13 and make sure they aren’t listed twice in the file? It looks like it is trying to use a signal twice.

I’ll check, but previously if a pin was used twice it would error out on load and not let me do anything.

Gah… And I just noticed neither of my fans work either ![]()

Grrrr.

Hot damn I figured it out…

Some idiot had a z_endstop set for the z1 stepper. So since z0 was set to probe and z1 was set to endstop, the software got flustered and tossed up errors. Delete the extra endstop from z1 and it worked.

I still have more configuring to do, but I should be melting plastic later today.

Left to do:

Mesh leveling

Raise Z before homing (I use clips to hold the glass on… it’s hitting it when homing)

Calibrate probe offset

The fan issues were a combination of wrong pin set in config and bad connections. Fan wires are really tiny and don’t crimp well. I used larger gauge wire for the connectors and then soldered them to the thinner fan wires.

On an unrelated note… I threw a current sensor on the heatbed. It’s pulling about 9.5A at initial power on and drops down to 8.8A after a few seconds of running. Well within the 20A of the 24v->12v buck converter I bought.

One last thing to debug… and this one is really stumping me.

For some reason, my extruder is turning with the z axis. If I tell it to extrude or retract, the stepper doesn’t move. If I tell the Z axis to go up or down, the extruder gear turns too.

This is really baffling me as I can’t see ‘why’ it would be doing this.

[include microprobe.cfg]

[include mainsail.cfg]

[include leveling.cfg][stepper_x]

step_pin: PE6

dir_pin: PE5

enable_pin: !PC14

microsteps: 16

rotation_distance: 40

endstop_pin: ^PF4

position_endstop: 0

position_max: 200

homing_speed: 50[stepper_y]

step_pin: PE2

dir_pin: PE1

enable_pin: !PE4

microsteps: 16

rotation_distance: 40

endstop_pin: ^PF3

position_endstop: 0

position_max: 200

homing_speed: 50[stepper_z]

step_pin: PB8

dir_pin: !PB7

enable_pin: !PE0

microsteps: 16

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop

position_min: -8

position_max: 180

homing_speed: 5

second_homing_speed: 3[stepper_z1]

step_pin: PB4

dir_pin: !PB3

enable_pin: !PB6

microsteps: 16

rotation_distance: 8[extruder]

step_pin: PG13

dir_pin: PG12

enable_pin: !PG15

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.4

filament_diameter: 1.75

heater_pin: PA0 # HE0

sensor_type: NTC 100K MGB18-104F39050L32

sensor_pin: PB0 # T0

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 250[heater_bed]

heater_pin: PF5

sensor_type: Generic 3950

sensor_pin: PB1 # TB

control: watermark

min_temp: 0

max_temp: 130[fan]

pin: PF9[heater_fan extruder_fan]

pin: PF7

heater: extruder

heater_temp: 50[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32h723xx_32000C000751313433343333-if00[temperature_fan pi_fan]

pin: PF6

sensor_type: temperature_host

control: watermark

shutdown_speed: 0

max_delta: 5

target_temp: 30

min_temp: 10

max_temp: 100[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100[pause_resume]

[display_status]

[virtual_sdcard]

path: ~/printer_data/gcodes[safe_z_home]

home_xy_position: 90,90

z_hop: 20########################################

TMC2209 configuration

########################################

[tmc2209 stepper_x]

uart_pin: PC13

#diag_pin: PF3

run_current: 0.800

stealthchop_threshold: 999999[tmc2209 stepper_y]

uart_pin: PE3

#diag_pin: PF4

run_current: 0.800

stealthchop_threshold: 999999[tmc2209 stepper_z]

uart_pin: PB9

#diag_pin: PF5

run_current: 0.650

stealthchop_threshold: 999999[tmc2209 stepper_z1]

uart_pin: PB5

#diag_pin: PC0

run_current: 0.650

stealthchop_threshold: 999999[tmc2209 extruder]

uart_pin: PG14

run_current: 0.800

stealthchop_threshold: 999999[board_pins]

aliases:

# EXP1 header

EXP1_1=PE9, EXP1_2=PE10,

EXP1_3=PE11, EXP1_4=PE12,

EXP1_5=PE13, EXP1_6=PE14, # Slot in the socket on this side

EXP1_7=PE15, EXP1_8=PB10,

EXP1_9=, EXP1_10=<5V>,# EXP2 header EXP2_1=PB14, EXP2_2=PB13, EXP2_3=PF7, EXP2_4=PB12, EXP2_5=PE7, EXP2_6=PB11, # Slot in the socket on this side EXP2_7=PE8, EXP2_8=<RST>, EXP2_9=<GND>, EXP2_10=<NC>

I got the pinouts for the board from here:

I am not seeing anything. Any solder bridges or anything on the bottom? Are all your jumpers in the right place?

As well I don’t see anything in your config that would cause that. Like Ryan said check the board for solder bridges and maybe check your wiring for rubs?

Wait you have the M8P right? Move the Extruder to a different socket and see if the issue follows

That’s my plan. Just haven’t gotten there yet.

Are there 8 drivers and 9 plugs? Z has option to run 2 steppers?

Yes. Just looked at my board sitting here and slot 3 has A and B plug. The way his Config is he should be skipping B

I think ya’ll are right. I do see 9 motor plugs on the board. I don’t see where that’s marked anywhere on the top of the board ![]()

That’s really hard to see when it’s bolted to a board…

Either way. I ran out and moved the extruder over one and everything worked.

I should be able to melt plastic tomorrow.

Oh. That also means I’m currently driving both z steppers on the same driver. I guess I should move the second z stepper over one too so they’re driven off of separate drivers.

Yeah the way your config is set up it “thinks” it has each on different drivers, but plugged in the way it is you just have a driver trying but doing nothing LOL. Just make sure your on the right one with your pins.

I get that completely, that’s why I uploaded a pic so you would know exactly which one it was

Now you are going to be dipping your toes in to the wonderful world of klipper tuning!