I already ordered. I added small bits and pieces like a drag knife and a coupler. ![]() Sorry.

Sorry. ![]()

No problem, maybe other people want to.

The jackpot will be in a box the wires should fit in a filament bag next to the box in a padded envelope.

Everything is fine, I did place an order already. ![]() Will have to crimp my cables then.

Will have to crimp my cables then.

If you think it will fit nevertheless though and I can still alter my order, I’d take five of those cables as well.

I would like that very much

Started a thread European group buy of jackpot boards about it

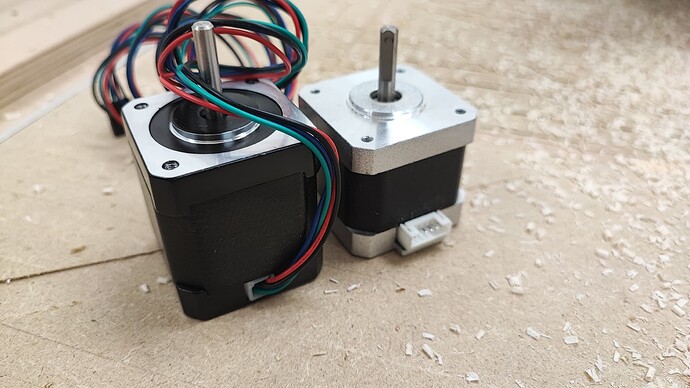

Operation Turbo is in full swing, see how tiny the old ones are…

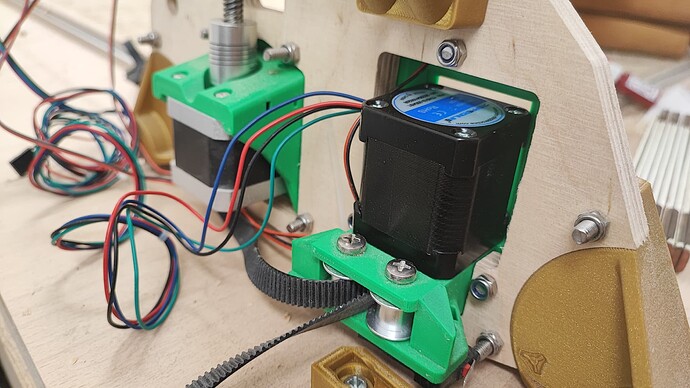

It helps when you can just unplug the old motors. I just have to follow the cables later. ![]()

Are you saying maybe I don’t need the laser after all?? ![]()

Are you milling out the bottom with that superfine bit too?

Yes, but it takes 1.5 hours and I am going on a short class trip tomorrow. ![]()

Let’s see hot it looks in the end. ![]()

After seeing Phillips and @dkj4linux versions I do believe I will attempt both. I have higher faith in doing it @Tokoloshe way as I’m familiar with the CNC and V bits. The laser is still EXTREMELY new to me and I’m not sure my laser is powerful enough to do it. But we shall see!

Make sure to run some tests. For the cat I had at least five test cuts before I found something that works. You should get away with a 30° endmill. I used a 60° before, it does also work but the inlays aren’t too deep afterwards, very shallow. The one I have now is marketed as 5.2° but this is only one side, so technically it’s 10.4° with a 0.25mm rounded tip, which does not seem to matter so far. For the signature it does not at all, because there are no sharp edges.

I believe I have some 15° in the drawer. I will have to dig though and see what all I can find

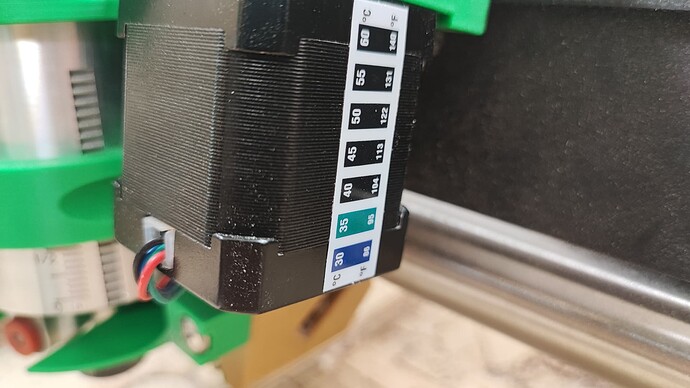

This is after a one-hour job (motors are rated 2A, I fed them with 1.5A). I might up the current on Z, maybe that helps against the dropping. ![]()

@bitingmidge: I am pretty confident to say that you do not need a laser for tiny inlays. The real truth will come to light tomorrow when I reveal it. ![]() I am happy for the time being though.

I am happy for the time being though.

Yeah just keep creeping up, 45C is a good temp in my testing. That is usually about 80% max current.

General idea says it does work. If my Z wasn’t dropping a bit all the time it would be a better fit, the very small portions of the feathers are too thin where the endmill went 1mm too deep, making them too small. Haven’t figured out the reason yet, seems to happen during a completely straight cut without Z movement as well, albeit a lot less. Really, really weird.

I am now going to stuff those tiny gaps with glue and sawdust. I am still okay with it, considering it’s so tiny. When I made the drawing, I did not really anticipate this. ![]()

That’s really fantastic.

But I’m pretty sure my wife still wants me to have a laser… ![]()

I’d be curious to discover what the time and supervision difference is between CNC and laser in this instance. I suspect the laser will win in our household because there’s a lot less noise.

Perhaps if I really get into inlay on the LR (assuming it actually gets finished), the laser will become more urgent. ![]()

I think I can proudly say that those turned out pretty well after the touch-up. No laser for you Peter. ![]() Now imagine that I a) hadn’t had a dropping Z (which I am still fighting with) and b) Estlcam 12 would not have effed up the final outlines with the carves. I know, excuses, but that’s all I got.

Now imagine that I a) hadn’t had a dropping Z (which I am still fighting with) and b) Estlcam 12 would not have effed up the final outlines with the carves. I know, excuses, but that’s all I got. ![]()

I like it alot! ![]()