Sieht sehr gut aus

Hey man - you should have a www forward for your site! When simply writing hawiwe.de, I get an error.

Just a nitpick, but makes a tiiiny difference on a phone keyboard…

Thanks, should work now. I never got around to check those settings though I noticed before that it does not work without www. Now it does. ![]()

Woop! 400. ![]()

![]()

What a great day!! Double tap!

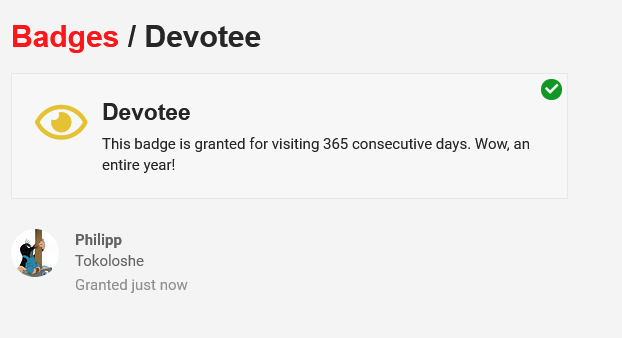

Finally. I can now sleep without being afraid of missing a day. Or is there a 2-year-trophy? ![]()

Checking that badge, it’s nice to see some lurkers who’ve got the badge but only created three posts in total. ![]()

Big day…what’s next!?

Going to bed, it’s past midnight now. ![]() But tomorrow we are going to the zoo, if the rain stops.

But tomorrow we are going to the zoo, if the rain stops. ![]() Oh, and just as I am typing it there was thunder and lightning.

Oh, and just as I am typing it there was thunder and lightning.

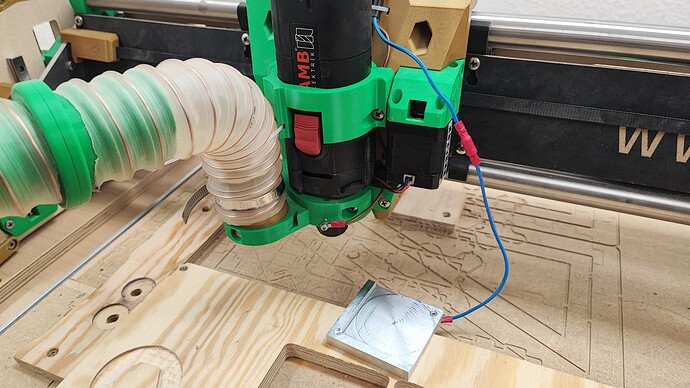

What size mill and how slow to make sure it did not break?

I used this one: https://www.amazon.de/SpeTool-Kugelkopffräser-Konische-Fräser-Beschichtung/dp/B01LZC1715. 750mm/min, 3mm DOC. I could have easily doubled the DOC though, I think.

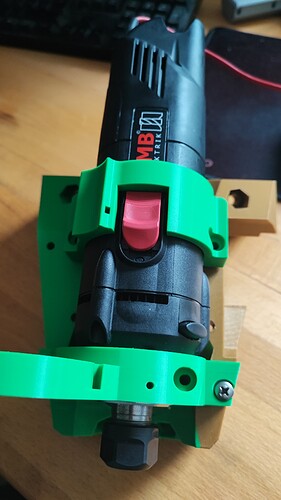

Tested the mount with the old core, it finally fits. Problem is that the router is 10mm too low. I’d like to raise it 10mm with the bottom mount, but then the top one wouldn’t fit any more. At the moment there are problems fitting the shoe and I might lose some space in Z which I can’t afford to lose because of the cutting board inlays. I have some ideas but I want to try that thing now…

The good thing is just extrude the bottom mount up 10 more mm, no problem and the top one doesn’t do too much so do the same for that, 10mm up and that little bit of bracing will be plenty.

How can I exclude a part from being extruded? I only need to extrude the “circle” part of the bottom mount, but don’t know how to. The whole model is a hot mess behind the curtain… ![]()

/edit: Found a workaround. ![]()

Should be able to hit extrude and select just the face you want to extrude

Yeah, but it’s one face. I extruded it, made another line on it and pushed the other part back again. Might have worked the other way round as well. ![]()

It works, it’s brilliant. Thanks to @Tobs_e and his grounding tip I can now really use my touchplate for the first time as well. The screw touches the router’s body, the plate itself can be quickly attached and taken off. Absolutely amazing!

I wish there were more of those around and we got some economies of scale happening. Compact form, nice overall design for CNC. Glad to see you get it dirty so quickly!

My in-laws were here and I got nearly 2.5 hours of uninterrupted workshoptime. It was really, really nice. ![]()

If I hadn’t been able to buy it used, it would never have happened. I can’t really justify spending 500€ on something if it is all working. But the RPM changes via software are really something cool, it just starts the spindle when it’s go time. Now I have to adjust all my settings from 24k in the tool list though… I am not sure yet when to use the minimum RPM of 3500 though. ![]()

It also feels to be much more rigid because the bottom mount grips the tip of the spindle and not, unlike the Makita, somewhere in the middle.

The dust shoe also fits. I added one of the magnets and it eliminates all the tiny noises. ![]() Getting it over the nut is hard, but works.

Getting it over the nut is hard, but works.

Ohhhhh dang! 2/3/4 flutes