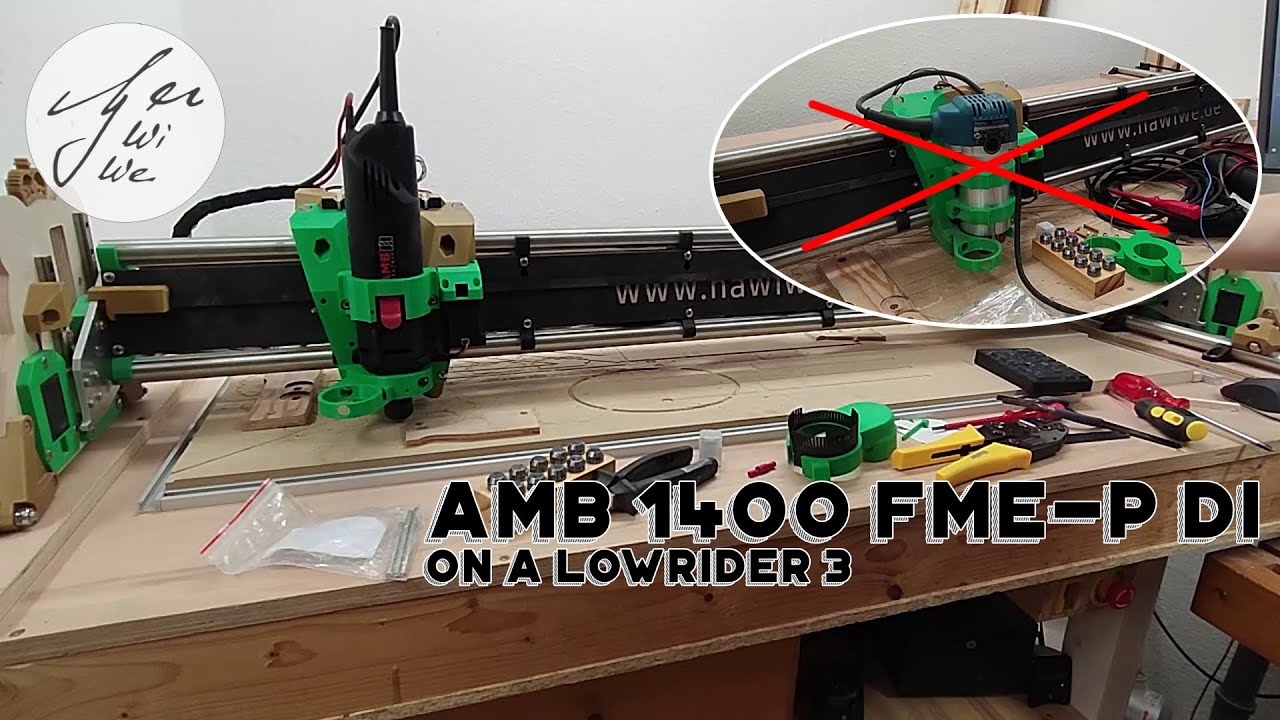

Model for the mount now published on Printables: Printables

Interesting, I didn’t expect it to be encased.

I do not understand what you mean, sorry. ![]()

I was expecting a spindle to look more metal and less plastic

Where did you get the cable chain?

Oh, that. It’s kind of a hybrid thingy somehow. You can’t use that version with the digital input outside of a CNC and all the others look exactly the same and don’t have any other hardware, so they are only build for that. So they either directly replace a Makita (but being more powerful) or in my case they replace the Makita with the advantages of a digitally controlled spindle but without the need of having a frequency inverter.

It’s printed. I really like it, but taking the tiny bits out gets a tad annoying. ![]() But you only do it so often…

But you only do it so often…

You can find it here: AR cable chain link opened by arek_r1 - Thingiverse There are also different sizes, the one on the side is a bit bigger, the one on the X is too small now for the touchplate cable, I attached it on the outside now. ![]()

Awesome. Can’t wait to see what you build with it… As well as how fast you will go ![]()

die Autoban Geschwindigkeiten von CNC (I do not think I said that right… Only got to German II ![]() )

)

It was pretty close. ![]()

I took this as a challenge and changed my cutout for the next box I was doing from a 3.175mm 1-flute to a 6mm 2-flute and shaved the time from ~33 to ~7 minutes. ![]()

Here is the full video with a few mistakes I made because I switched rather spontaneously and left the wrong tool for the finishing pass. And apparently I deleted two holes… ![]()

The dust collection can’t catch it all. It’s a bad Pokemon trainer…

It stopped twice because my touchplate ghost triggered (there isn’t one connected…). Need to fix that somehow. I finally fixed my loose endstop though, so no more wrong triggers there. ![]()

It would be pretty cool with a matching v1e cable chain? Maybe with the logo in some way?

It‘s still there btw… Your prediction might have come true. ![]()

Lol, yeah

Do you have a link to the mounts on the core and on the struts? I may have missed it in the topic ![]()

Damn… after switching to 6mm bits based on your advices I was pretty happy with my new personal record of 4mm DOC at 3000mm/s in particle board…

Now you give me a new challenge! ![]()

I don’t exactly know which mounts you mean, sorry. Could you specify?

I aim to please. ![]() I am trying to push it. I know that most people here say it does not matter how long it takes since it is a hobby, but I want to. I don’t know why exactly. Maybe because at the moment workshop time is tight.

I am trying to push it. I know that most people here say it does not matter how long it takes since it is a hobby, but I want to. I don’t know why exactly. Maybe because at the moment workshop time is tight. ![]() The CNC sounds horrible with those speeds, but there is no stuttering that appears with other cuts that are a tad too fast. And nearly all professional CNC videos sound the same. One gets so used to the 10k rpm that is so quiet.

The CNC sounds horrible with those speeds, but there is no stuttering that appears with other cuts that are a tad too fast. And nearly all professional CNC videos sound the same. One gets so used to the 10k rpm that is so quiet. ![]()

The 3k looks really nice, like butter.

The part where the dragchain attaches on top of the core+ the channel where it sits beside the struts ![]()

BTW, what spindle speed are you running for those rapid cuts?

I Always fear I may burn the cutter if I spin too fast…

I’m not certain this is what you’re asking about, but maybe this is what you were asking for? Designs I made and posted on Printables:

LowRider 3 CNC - Drag Chain Mount (v1.0)

LowRider 3 plasma CNC - Drag Chain Mount revised for large 20x40 drag chain (v1.13)

Yeah, Doug’s first link is where I got them. ![]()

24k rpm. It’s not been a problem so far. If you burn it, you are not going fast enough. ![]()

Heck yeah, nice! Try a bit deeper, looks like you still had plenty of room for more material removal.