Did you figure this out already?

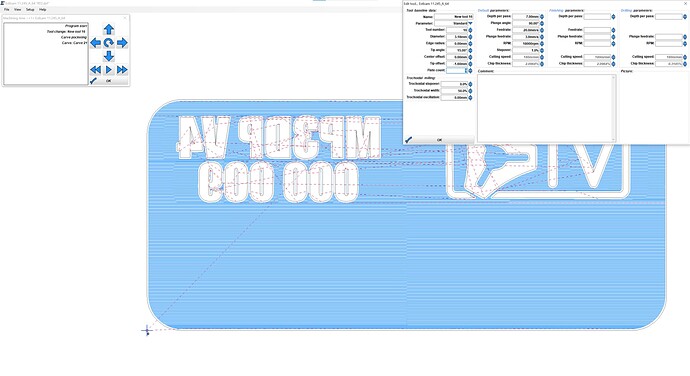

Been trying to make some straight line cuts with 90 deg V-bit (NOT trochoidal) in Polycarbonate.

-

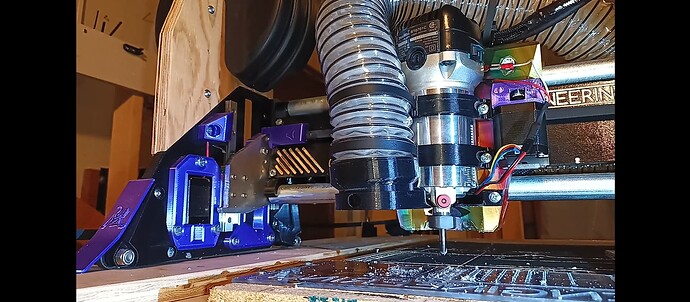

DOC = 2mm, XY Feedrate = 20mm/s results in LR3 doing major bunny hopping (chatter?), bearing wheels lift up, my struts are Ply, so not huge amount of weight on the gantry.

-

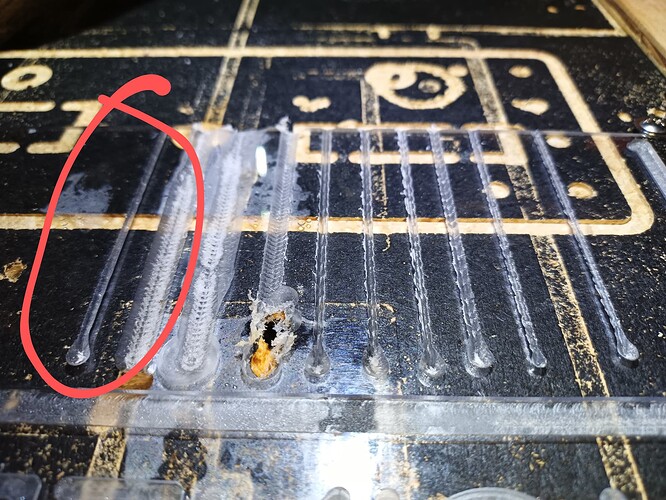

DOC = 2mm, XY Feedrate = 5mm/s results in too much heat building up, globs of plastic form around the bit and scratch the crap out of the surrounding area. Don’t do this unless distressed/disturbed look is your thing.

-

DOC = 0.5mm XY Feedrate = 15mm/s results in fine dust with minor bunny hopping.

Discovered and fix Core being too loose, adjusted only couple months ago. Sharpie marked line on bolt and nuts to help detect whether they’re loosen over time, and/or something else is contributing to Core bearings loosen from the 3/4" EMT.

Have a weighted vest with sand pouches, wondering whether to load up the gantry with sand-bags/something see if that helps?

Back up option is to live with wider lines and use Trochoidal so deeper DOC can be used to create chips.

For V Bit, should toolpath software ideally enable specifying material removal rate per pass, instead of same DOC for each pass, seems like deeper passes need to go slower, but earlier shallower cuts shouldn’t be hampered with slower feedrates that work for deeper cuts. This is a non-issue if Trochoidal cutting I guess.