So assume your ribs must be cut lengthwise on a 4x8 sheet. You have 4’ to work with.

Make them under about 11-7/8" tall and you get 4. Maybe enough, but…

Make them under about 9-3/8" and you get 5

Make them under 7-7/8" and you get 6

Make them 6-1/2" and you get 7. For me this is a pretty good place if the table has to be 8’ long, because the ribs will be a little under 16" apart, which should be plenty rigid. Of course you don’t get any spars from that sheet, you will have about 3’ of offcut from the end, which should give you some material for other fixtures.

Now let’s play devil’s advocate and say 5-1/4", which gives you 9. Use 7 of those as ribs, and 2 as interior spars. Now you’re getting too short to have much useful space inside the table but you have a torsion grid inside that is 6x4, ~16" x ~12" – lots of rigidity. You still need the edge platforms to mount the LR3 rails and the side panels for the box, but this seems to be not a bad compromise. 5" doesn’t leave room for much more than a 3" tall opening though, so not sure if it’s much for your needs. Let’s say it isnt, and you want to conserve…

At about 4-1/4" you get 11 strips. Which gets your entire grid. 7 ribs, 4 spars. You still need the rails for the machine, but these might be strut or other material. These rails need to be about 9’ anyway so they have to come from another source (assuming full sheet capacity) if I were designing this as a budget /default table, this is probably where I would go. This lets you cut a full grid for a 4x8 sheet (or 49"x97" for MDF).

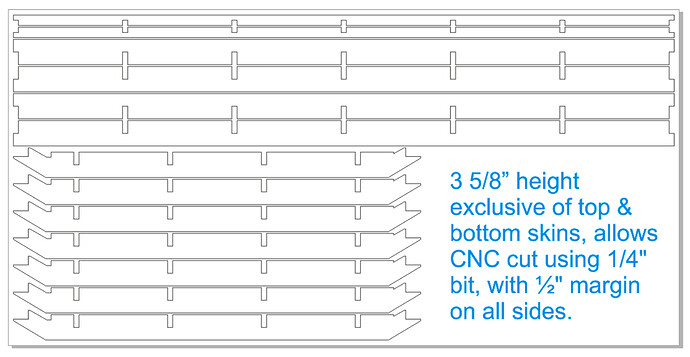

If you just want the whole thing 8’ long, about 3-1/2" gets you 13 strips. I don’t know if you would want to go much thinner than that.

I’ve rounded the sizes a bit to account for about a 1/8" kerf from the saw or router bit. If you are using a 1/4" router bit to cut these out, you’d need to go a bit smaller. I’m personally thinking about a tablesaw, actually.

Of these choices, the 9-3/8" option gives you 4 chambers, which is probably good. 4 struts gives you about a 16" depth and leaves you a couple of 4-1/2" strips from the second sheet which can either be your rails or table supports. This actually seems like a pretty good setup to me. The openings could be 6-1/2" high which is more than enough space to reach in.