Ok. I am curious about what print speeds and quality this will give?

I am in the last part of class and will be headed home this afternoon. Hopefully I’ll be able to provide some info for this soon!! I did make one print with it before I left and it came out well. But my stock bed decided it didn’t want to heat anymore. I had already ordered a replacement from AliExpress and it was delivered a few days ago so hopefully I can get it installed with the new 120v heater and get some good test prints done.

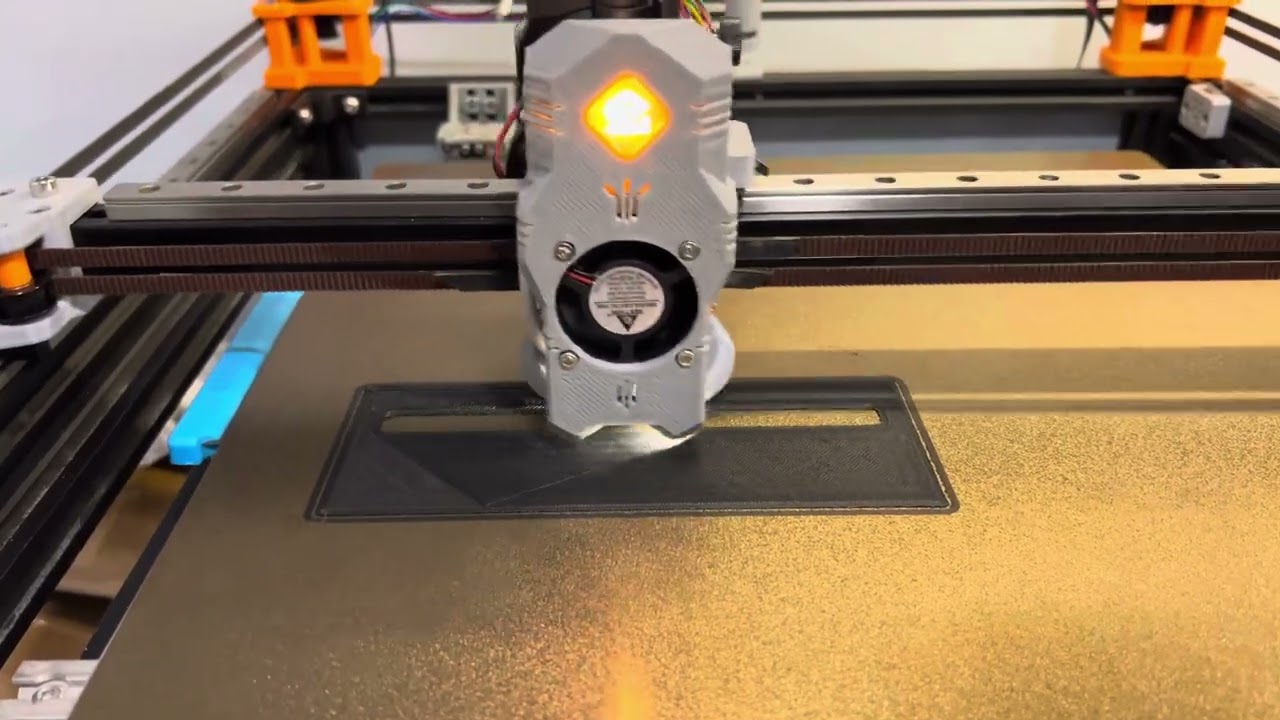

Got the new bed installed tonight and started a print to test it out. Haven’t done any tuning yet. Printer is running 200 mm/s

Looks nice! Did you use ASA or ABS for the parts?

And how would you rate the quality of your prints?

I used ASA and they were very good parts. Everything went together well! I got the Fabreeko kit so it came with just about everything I needed which was real nice!

Thanks for this awesome post sharing your experience.

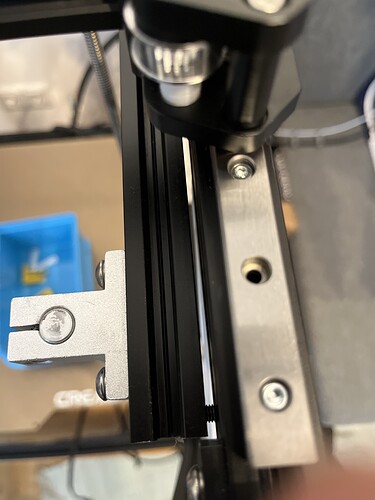

I am currently building mine and for me the biggest trouble so far are the two y-axis rails.

The whole z-rod assembly twists the rails inwards slightly which caused really bad binding.

Removing tension from the z-rods by loosening the upper inner extrusion screws really helped here. Not sure yet how I will fix that or even which part of the frame is bent or not properly aligned. I can move my bed up and down no problem so the rods must be almost parallel

Are you sure you have your hotend cooler built in the right way? To me it looks like it’s blowing outwards

That has been fixed. Thanks!

I didn’t not have that issue on mine. That defiantly isn’t right though and once you tighten it back down its going to pull on it again. Hopefully you can figure out the cause and get that straight.

Thanks. It looks like the whole frame is skewed left to right. Wish I had a way to get the extrusions squared off perfectly but I haven’t. So all I can try is to use my corner brackets which I used on the sides to increase rigidity and try to square the frame that way. Any other hack to cut the aluminum extrusions etc will probably just make it worse

Was it? It is worth the money?

Well I ordered the kit to do my Ender 5 Pro as well if that tells you anything lol. Its a whole different animal now. I am real happy with all of the choices I made. The extruder/hotend are insane. I ran a flow test to 50mm^3 and it never skipped a beat. Still have some more final tuning to do but its printing great. Got side tracked from it with the V5 project but its still there and doing well!

Ok. Perhaps you could post a video of it printing something?

Hey yah doing this build myself. I’m at the wiring stage and was hoping you might be able to help me with where the wiring for the orbiter 2.0 goes into BTR SKR mini e3 v3

I will pull up the Pin out and try to mark it for where it goes. But mine is not wired that way. I went CANBUS with an EBB36 toolhead board and all of mine is wired there

Just ran across this. I am currently working on one myself. I am waiting on z rails and leadscrews at the moment but working on the Printer config while I wait.

Awesome! So I assume you are doing Hydra as well since your waiting on Z parts. I did not do Hydra on my E5+ since it was already dual Z, but I did separate the Z motors so I can do Z tilt on it now.

I am currently working on doing the Merc One.1 conversion on my E5 Pro as well. That one I plan to do Hydra on, I have the hardware kit and the Z rails but don’t have the lead screws yet. So that will come a little later.

What extruder/hot end/tool head did you decide to go with?

Any more videos?

Not recently but hopefully soon. That is the printer I am putting the ERCF on lol. Also almost done with the Mercury One.1 Conversion on my Ender 5 Pro as well

Looking forward to seeing more of this build and the ERCF!