that is a substantial improvement over my 10:15 I think it was. Way better than the guy who said it took him 30+

I’m going to guess the slicer settings or nozzle size have something to do with that 30+ hours.

I have a mostly stock Ender 3 Pro running a 0.6 nozzle, that is nowhere near winning any speed races any time soon, and my LR3 core printed in ~17 hours I believe.

17 hrs sounds about right for the ones I have done. The last one was the longest at around 23 hrs but it was printed in PETG and I slowed it way down. I think the V4 could do it in under 10 now but I haven’t tried. Still more tuning to do. I know I have a bad toothed idler in the back. I can hear it squeaking and when I move by hand I can feel it’s not right. Going to order all new idlers from Ryan and change them all when I get back. I ended up with a mix of some from him and some from Amazon so start fresh and then I’ll know for sure.

flow rates more than anything else. Klipper helps a tons too

Acceleration makes a much larger difference than I ever realized as well

I agree. Mine was printed with a .4mm nozzle. I expect that using a .6 and a much higher layer height would make a huge difference but not sure the flow capabilities would keep up with the 125mm/s I used.

My max flow rate is 12 mm3/s and running Marlin.

0.6 nozzle. 0.24 layer height. Print time 15h 12m

Even my 0.4 nozzle with 0.2 layer height profile, with max speed of 50mm/s is only showing a 24h print. I’d be interested to see what the settings were that caused it to take 30h

I had a .4 nozzle and printed about the same speed, but I am sure you were able to flow more and didnt have to dial back in some the ways I was forced to.

Just looked again, I was printing at 110mm/s with accels at 2500 for the outer wall and 3k everywhere else. Not sure why I slowed that down from my normal 5k through the unseen sections. But I also was only running .5 lines on the skin which is also odd for me.

If guessing .01, and depending on what type of infill is selected can also make a difference, but it’s not something talked about often.

And for clarity, I’m not referring to % of infill, obviously that can cause a factor as well, but the different types (or styles, patterns however the best term is) I’ve seen impact the print time.

Of course no infill, obviously seems to decrease the time greatly, which is needed when 3D printing objects for flight. ![]()

Nope, you’re right… my fault. I forgot to set my infill percent. My 24h goes to 30h at 40% infill

That’s

0.4 Nozzle

0.2 Layer height.

Max speed 50mm/s

Max volumetric flow rate 6 mm3/s

I don’t even remember what led to this conversation anymore lol

I changed my printer to a 0.6 nozzle specifically because I was printing the Lowrider parts and didn’t want to have such long prints

My apologies Mike if I caused confusion, I was more guessing at what might have occurred on the person doing the 30 hr print.

Mine was close to 30, however it’s because I intentionally reduced the speed to 50%. Being on a bed slinger, I didn’t want to stand a chance of that weight separating from the bed.

I’m one of those people who doesn’t care about the time, as much as the quality. The prints are for my enjoyment, and I enjoy watching the print, so speed has never been an issue for me. But understand why speed can be an issue for others, and I do like watching the newer printers moving faster. I feel my days are numbered before an upgrade, but I’m trying to hold off for a multi-color with minimal waste.

Not at all… I was genuinely curious when I heard that because I think of my machine as being terribly slow, and I remember that mine was much quicker than that.

But I also forget how much infill etc can wreak havoc on times at those model sizes too

For me, it’s that I just don’t trust my printer to go that long continuously without messing up ![]()

This might be so true that it breaks the internet. Lol

Now click print and lets see how it looks after 4hrs and 40 min lol

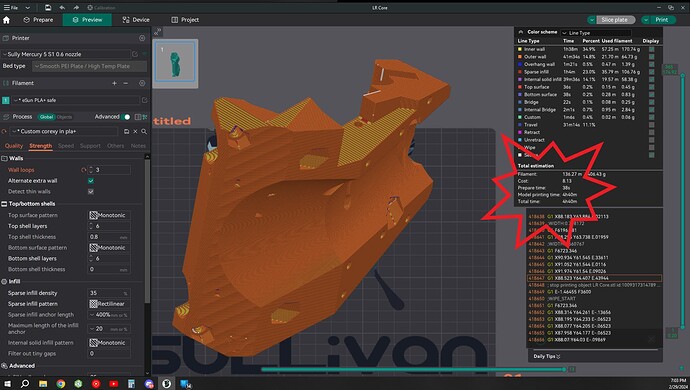

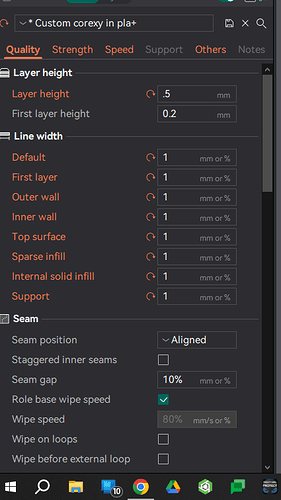

Im curious too. but not blow 1/3 of a roll of filament just to see curious. That is set to lay down some serious plastic and not so much move fast. I think it is roughly 100mm/sec, but Im not actually controlling that. I have it set to limit flow to 30 cubes. After printing a vase mode trash can above that flow, I am no worried too much honestly. But .48 layer height, .9 walls gets me to that 4hrs 40 minutes according to orca.

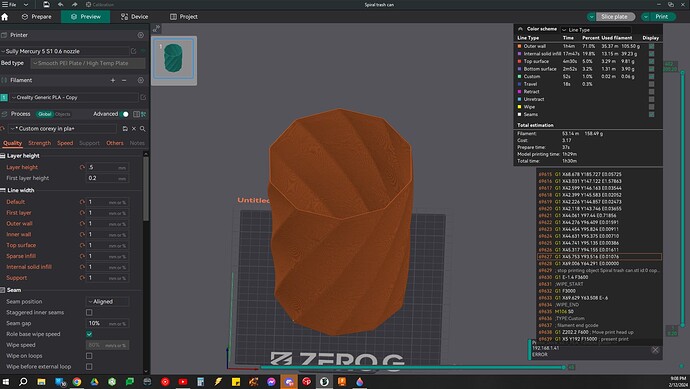

Picture of the vase mode trash can for reference:

I had the flow max set on that print at 34 cubes based off a flow test done before hand

How is this build coming along?

I just got back home yesterday afternoon. I messed around with it some but having some issues. My can bus cable to the tool head keeps screwing up. Just made an order from Fabreeko for the rest of the rails for the V5 build, also picked up the build kit for my Ender 5 Pro to do the same mod as this one, and I also picked up 3 meters of their canbus cable. Hoping that will get me straightened up and running better.

Did you resolve any of the issues?

I got frustrated and got the canbus cable temporarily fixed. Have learned that I’m not a huge fan of microfit connectors lol. But with that I was finally able to get it to a point of doing a test print. And at that point the bed decided it didn’t want to heat anymore. Not sure if it’s the element in the bed or the separate mosfet that decided it didn’t want to work anymore. It worked fine the other day when I ran PID tuning on it. Either way I have a replacement on the way from AliExpress already so not going to worry about it. I was test printing with Pla and a small part so I just ran it with the bed temp set to 0 and it printed great!!! Then I had to leave for school this week. Hoping to get more time with it when I get back home and get it dialed in better. Hopefully the bed will show up before I get back. Hard to say with it being AliExpress lol. Tracking just shows that it completed export customs clearance. Says between Feb 28 and March 15 for delivery lol