Because the meds have worn off, and I enjoy spewing this bit of triviata every now and again:

Conduit and Pipe are important because of the amount of stuff you can push through them, so they tend to be measured by ID (inner diameter), so you can quickly tell how much cabling/fluid/gas/etc. you can get through it. Then you might get a wall thickness so you can figure out how much pressure you can put that stuff under before you get a blowout.

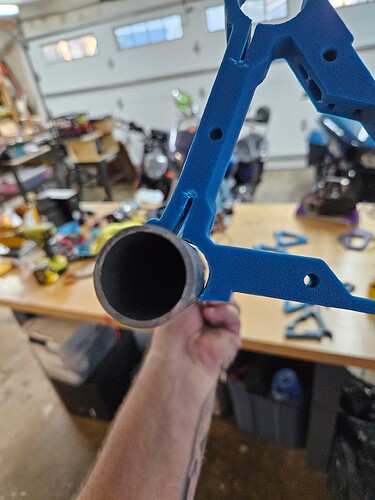

Tubing is usually important as an architectural or structural component, so it’s measured by OD (outside diameter), so you can tell where it will fit. You’re more likely to get a wall thickness, since that’s very important to how much stuff it can hold up.

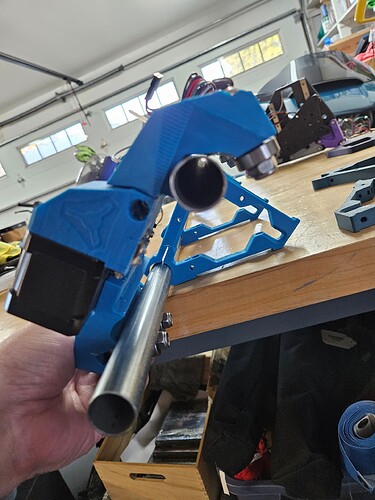

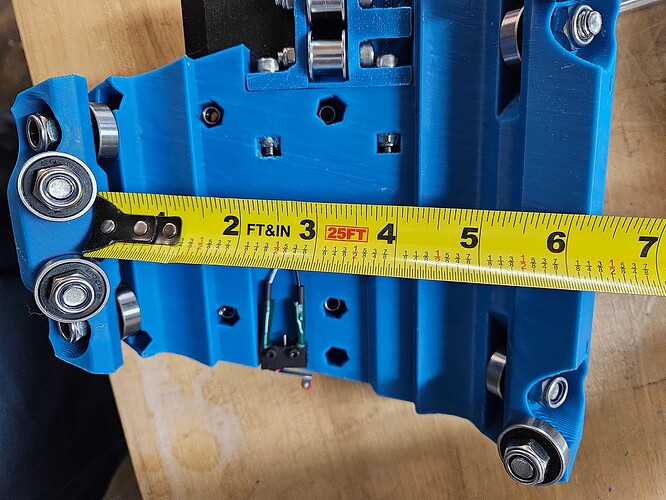

So, Ryan has standardized on three sizes: ‘C’, ‘F’, & ‘J’, which are easiest to remember as Conduit (3/4" ID EMT conduit @ 23.5mm OD, found in North America), Foreign (25mm OD tubing for the rest of the world), and Jumbo (1" OD tubing @ 25.4mm).

Yes, it’s nonsensical, but that’s construction for you. The trickiest is usually pipe, because sometimes, that gets measured by OD, but conduit and tubing are pretty consistent in how they are measured. It’s definitely a case where you want to read the fine print, or be very clear in your request/requirements.

If you do look at tubing, you do need to think about wall thickness. Ryan has some guidance on wall thickness (0.065" - 0.120"), and in general, thicker is stiffer, but it’s also heavier. So you’ll reach either a point of diminishing returns where it starts sagging under its own weight, or you have to slow d o w n because things have gotten too heavy. i.e., It’s been thought about, and tested on plenty of machines, and the suggestions are very good.