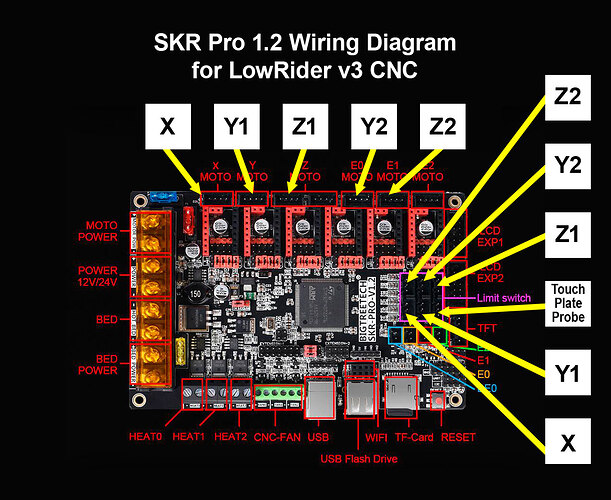

Is that the reset all coordinates option? I don’t see any other options in the preflashed firmware.

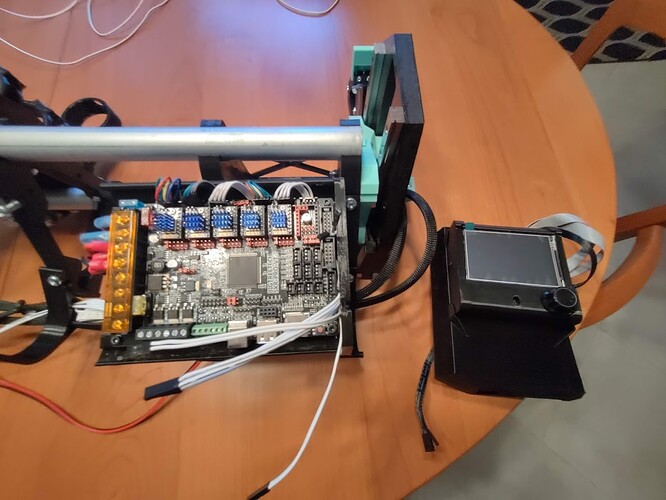

the touch interface, only seems to have a customized “emergency stop” other than that looks like a normal 3d printer touch interface but with V1 color scheme, which i read elsewhere in the forum here that is mainly because the touch customization was too much of a pain. I may look further into customizing the touch firmware, but only well after i have this thing performing well completely stock. I’m comfortable with 3d printer firmware, but the whole CNC is very new to me.

I’m trying to understand how resetting to “0” before a print and how the touchplate probe works.

When I did the crown test, I first did it in the air and noticed that just starting ‘engraving’ immediately after hitting print, with no pause for zeroing things out before it ‘cut’. So when I printed the crown for real, I just manually moved my core (through the interface) to the proper position on my paper notebook, and then when satisfied hit print and it did it’s thing.

just trying to understand how the touchplate probe works and how/what to do in estlcam/touch screen for zeroing things out when I go to do real cuts.

I did load all of the recommended configs for estlcam for pre and post gcode, but don’t really understand how the touchplate matters at all with it. The beginning custom gcode snippet essentially just says at start, where it is right at the time of starting print is all zeroed out, then it homes, and then it starts as soon as I hit resume, there seems to be no prompts for the touch plate to be used at all during this process. Am I missing something?

G91 ; Relative positioning, just in case

G92 X0 Y0 Z0 ; Set Current position to 0, all axes

G00 Z5.0000 F500 ; Raise Z 5mm at 8.3mm/s to clear clamps and screws

G28 X Y Z ; Home in order, w/zprobe

G92 Z0.5 ; Account for probe thickness (set your thickness)

G00 Z5.000 F500 ; Raise Z probe off of surface

M00 ; pause for LCD button press

M03 S<s> ; PID, set spindle speed

G90 ; Absolute positioning, just in case

I also didn’t see anything in the marlin mode or touch mode to do any type of zplate or origin zeroing unless that “reset all coordinates” is what you manually hit after moving the spindle to your origin point.

Many of you probably have this down as you’ve been doing this for a while, but this part eludes me from what I’ve been able to search for here.

Thanks for being patient with me. So far building this thing has been the best kind of therapy and I’m excited to get it cutting, once I understand these core essentials