Also, just for a record here in my history, and that may be a help to someone else…

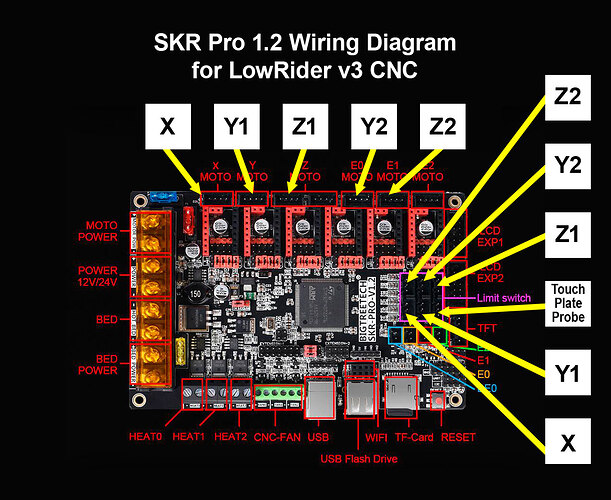

LowRider 3 Dual End Stop board pins while using pre-configured firmware (“V1CNC_SkrPro_DualLR_2209-2.0.9.2”) for SKR Pro v1.2 — Dual End Stops for LowRider

This is the pin configuration that finally worked for my end stops:

| End Stop | Connected to |

|---|---|

| X | X min |

| Y1 | Y-min |

| Z1 | E2 |

| Y2 | E1 |

| Z2 | E0 |

And here is a graphic illustrating it: