Very glad you didn’t try to go with ball screws. I have another one failing and that’s with routine pm. Despite best efforts, debris still manages to get in the balls and destroy them. The culprit here are aluminum chips.

On the few machines I’ve seen with ball screws, they were inside some sort of protective sleeve, like a bellows.

We have some that are under saw tables with shields around them. You’d be amazed how much crap gets on and in them. Even with preventative maintenance

The linear rails right next to the ball screw is not having any issues? They have recirculating balls in them as well, they just don’t move nearly as much.

Hey Ryan. I am in the middle of a lowrider build and of course am being patient…!! !! !!!

But I do have a question… What is the loss/gain on the X vs the LR2. My table has a little flexibility with the width, but will we need to widen to get back to a 4x8 cut?

Yes, I am being patient… really, I am… … sorta… Also, as far as hardware, what/how much will be re-usable?..

Patients… I know…

Yes. The footprint is wider but not as long. Although the actual footprint is overall smaller… What I have listed as the current rough dims is X usable +180mm for the table surface width(gives you 5-14mm extra working width).

The linear rails have wipers on them and we have very few problems with them if any.

Just visited the site after a few months away, and stunned by this rapid development! So exciting. I actually came to price out an LR2 kit, and find stl’s for printing, and was redirected, so it looks like I’ll be holding off and doing an LR3

One quick question- does this retain the familiar shape of the LR - where the Y axis is essentially unrestricted and it can be used on a fold up table- or will it be more like the MPCNC where the work area is finite and surrounded by rigid tubes?

Reason I ask is that I planned to add an LR2 to my new shop, but the only way it work ma is if it can be ‘parked’ and most of the table is folded up and out of the way, when not in use. I’m

Hoping I’ll still be able to do this with the LR3

Thanks!

Looking forward to the pics and vids

So Far, parking, is easier.

Come on ryan. Give us some meat. Start teasing it!

Hope that is set to stun!

Take my money!!

i mean, share all your hard work for free and hope the universe returns some love to you for it one day

Have we said thanks lately? Thanks Ryan

But really though feel free to keep taking pics!

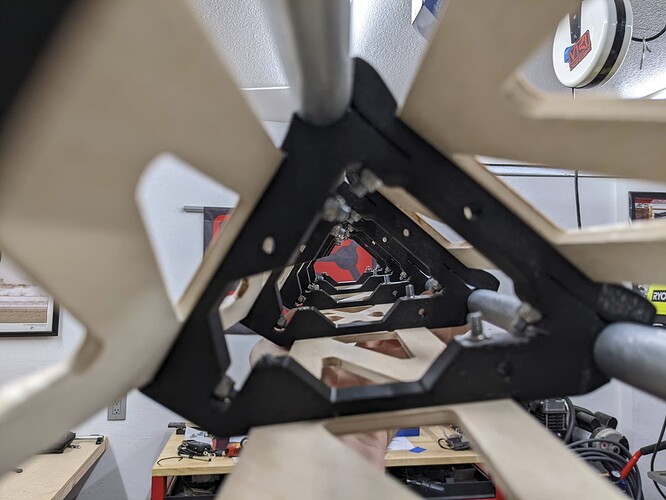

Hot dog that is a lot of printed and cut parts for a gantry? Looks super sturdy and maybe following the printnc approach to build good enough then use it to upgrade?

Nice frame, is that surf, or smoke?

It’s an old framed poster from my early days. La Roca Bruja, Arron Chang. I dreamed of going there to tune up my backside snaps.

It is getting close.

If you have an opinion on licensing, let’s hear it over here, New machine Licensing

is this an unwanted teaser too?

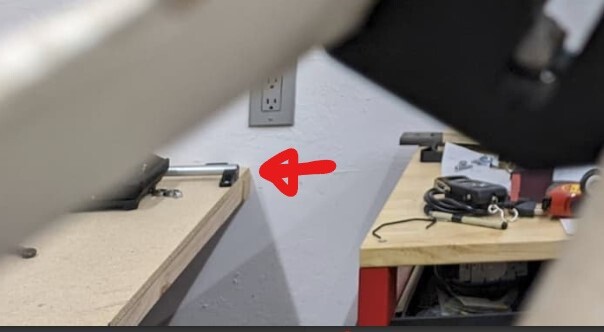

Looks like a tube instead of skatewheels, with mounted onto it a belt tensioner - no?

Would be a good upgrade I suspect ![]()

Will it be possible to mill those parts out of 18mm plywood instead of printing it?

Figure why not use a LR to make a new LR ![]()

Now I am starting to doubt, if I should upgrade my L2, or abandon it and look for the LR3 :s

Must… Not… Reveal… Spoilers…

Well, for the parts in the picture, I can’t see it being easy to mill these because of the bolt holes through at right angles. It would be difficult without 5 axis milling… But might be possible with a really good jig, I suppose…

I think some of us have discovered that the LR2 is more capable than we previously thought. I might not invest a lot in upgrading the LR2 yet, but I would not stop building it if I had the parts in hand.