https://forum.v1e.com/t/finally-some-pictures-of-my-kit-car-project/22344/62

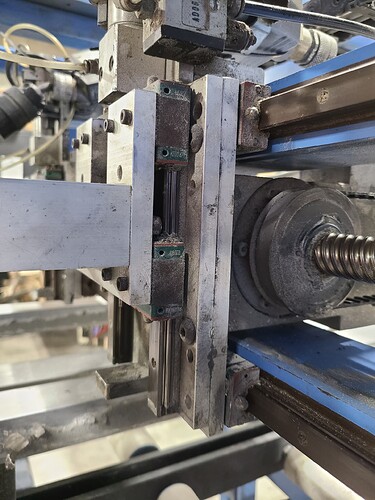

Two types. These linear bearings have very few failures. The ballscrew has a circular brush type sweep drilled and tapped into the pulley. Also can use those on round shafts. This is an odd set up as the ball screw is fixed and the carraige moves by rotating around it.

Interesting. The cheap linear bearings do have the sweep built in, I just don’t trust it, but I also have not tested it. There is room for some screw holes if we need to add something more later.

I really expected those to be more robust. That ball screw one though, that looks major.

I would love to help beta test but I haven’t quite finished my LR2 yet. (Probably because I’m making to many mods on the way )

I do have 20+ years of machine design, so I’m happy to help review the design.

Andrew

A last minute feature request…While you have the CAD file open add some utility holes to the router plate for attaching accessories. People want to attach all kinds of weirdness no their machines and a few standardized mount points would make it easier to share.

Those linear bearings have run for over 5+ years 24/7 without an issue (and the operators are not good at cleaning the machine). A little grease pumped in them monthly, keeps them going. The machine in the picture was being rebuilt and upgraded with all new bearings and 2 hp 3 phase spindle motors. It has dual spindles for higher volume production.

Well my mind is blown.

Yes, they’re neat to watch move too.

Perhaps i should clarify that… lol. The ball screw shaft is fixed and the ball screw nut rotates to move the carriage… driven by the pulley in the picture… y axis is 10’, x axis is 16’ and same drive setup. No z axis. Cuts flat material and raise and lower spindles with pneumatic cylinders. Operators can raise and lower the table height with hand crank to maximize full use bits. These machines are being phased out and replaced with our custom machines. Most of our other machines use z axis ball screws. Some use rack and pinion and a few belts. Have much fewer issues with the belt drive machines.

The one positive thing about this design is the frame is a heavy steel box. All the drive hardware and bearings are mounted from the top. This keeps them, for the most part, up out of the debris.

Dang, that says a lot if you are even willing to touch my designs. shoot I am sure you have seen it all…even a 3D printed CNC now. ![]()

Good Idea. I have a couple extra now but they are inline. I do have room to add a few more. Thanks!

That is awesome! I feel better now, wood dust should not be a huge worry then, an if you are cutting metal we will figure out a little extra protection.

You just keep easing my mind. I keep thinking if we had any issues I would use two belts per axis before requiring long screws of any sort.

I will be in our plant that does the metal next week and get a picture of those linear bearings. Again, we experience very few issues with linear bearings. More issues are from the ball screws, mostly lack of PM’s. If not maintained the small debris works it’s way in and destroys the balls inside. I had sent you a picture of one that locked up a while back.

Hi everyone. I’m new here (and to CNCs in general). Just wondering if the LR2 kits are likely to start shipping again soon, or if there’s an update in terms of turnaround time for the LR3? I have a small business and we could really, really use a CNC to free up my hands a bit.

The last update from Ryan on LR2 kits was in a different post:

Specifically:

LowRider 2 -

-I am not going to make any kits after I sell out of what I have on hand.

The LR3 is not ready yet. It has a few milestones to make it through before it is ready and each of those could be quick, or take some time.

There are no LR kits available right now.

Also, welcome!

The LR2 parts aren’t too difficult to source. The V1 shop still has most of the hardware that you need. Control boards, Motors, wheels, skate bearings, belt, and pulleys are all available there, and you can get the control electronics pre-flashed, which is nice. You can also still get the printed and flat parts for the LR2 from the shop.

The #6-32 screws and nuts, M3 and M5 screws and nuts, and 5/16" (or M8) nuts and bolts should all be findable at a nut and bolt supply place. A little less convenient, but the BOM is a good list of what you need. If you;'re doing things a bit differently (Say, using thicker Y plates) or if you have other ideas for mounting the control board, you’ll need some additional hardware anyhow. It is probably not a bad idea to plan that out as well.

For the LR3, if you’re looking at this for a business, going with the newest might not be the best plan. There are likely to be a few things to work out, and a known good machine is more likely to start making you a reliable income sooner, I’d think. I’m just a hobbyist, and enjoy tinkering with the machines almost as much as what I make with them.

Just to keep you all informed. I am getting really close. I have made a bunch of minor tweaks, working on any printabuility stuff. Really trying to get ready for the beta in a day or two. Reprinting the core again to try and get that dialed in, then I will keep going.

Beta crew, I will start some sort of thread of private group to get this going. If you can just see what you can do about getting four 150mm 12H rails, you can go longer if you have the means to cut the rails (abbrasive saw or cuttoff disk). Longer ones can be less expensive in small quantities.

MGN12H rails arriving today, 2 fresh spools of PLA arrived 15 minutes ago. I have 1/2" and 3/4" conduit already, as well as a good supply of 1" DOM steel.

Looking forward to this!

Bummed that i couldn’t throw my hat in the ring to beta test. Two reasons i held back are i don’t have a lowrider yet, built my mpcnc first (2’x3’ working area). Was waiting for the upgrade of the lr. Also don’t have 3d printer yet, but building one now. I do have 25+ years of experience with custom industrial machinery (designing, building and programming) if you need technical assistance. If there is someone beta testing in the Tampa Florida area, I’d be interesting in collaborating with them to help further this project.

Edited, because i can’t spell for shit today… lol

Linear Rails will be in tomorrow couldn’t find 150mm endup getting 2- 400mm with dual pillows. Like Dan, I have SS and DOM and planty of filament on hand, will get conduit once I know what I need. I didn’t order any bearings as I figure between the LR and the Burly Core (that still assembled) I will have enough for the build.

I didn’t have time to cut anything with the LR this weekend, bunch of kids stuff and snow to clean up. Tomorrow afternoon and I will get to it.

Cool, I just got back from the park the new core is printing great. So that means I will start the rest of the parts printing and get to Assembly tomorrow, I hope.

I put some zip tie holes in it…I am much happier now.

There are 3 “extra” Mount holes and 3 Zip tie positions. That should be good?

No worries, we will give it a good run and let you all see it ASAP. I am confident there will be more new projects in the works!