Im planning to build a MP3DP and im starting to order a few parts. Going with 300x300x400. Got all the Linear rail ordered and the 2020 extrusion. Part im striking out on is the aluminum build plate. Maybe im calling it the wrong thing. I ordered a 120v 750w heater for a 300x300 plate. Also found a spring steel PEI plate to go on it. I just cant seem to find the actual aluminum plate that all this mounts too. This will be my first ever DIY built 3d printer. Currently have an Ender 5 plus, Ender 5 Pro and CR10SPro V2. But the wife and kids keep those pretty busy when im home. Mostly i just want to build my own and really want to try out the corexy. Anyways…can anyone point me in the direction of what im looking for? Thanks!!!

Will this one work?

Not sure if the mounting holes will match up. V1.8 is an old design. If you can find a diagram of hole locations and ask @vicious1 he might have an answer. Otherwise a local metal shop is your best bet.

Yeah the heated beds are actually kinda hard to find for me as well. The one you linked is just a plate of aluminum, you will still need a heater and thermistor, and a surface to print on. You might get a better deal finding a more complete package. At that size you might need to go 24v or mains voltage as well, not sure.

Adding bed mounting holes in my CAD shouldn’t be too bad, I did leave a square in there just in case to extrude instead of that minimal shape I have.

I am on the hunt for some 200mmx200mm beds, I usually just get the mk3 direct pcb ones, when I looked for larger it got a lot more expensive.

This one is out of stock, but…$30, 300 x 300mm MK2A Heated Bed

They have a mains powered 400x400 for $120, needs a thermistor. High Power Heated Bed w/ Solid State Relay and Mounting Hardware (120v AC) - 400mm x 400mm - ZYLtech Engineering, LLC

I already ordered a 120v 750w heater and insulation. I thought I would be able to just find the aluminum easy lol. That’s what I get for acting before double checking everything. I have a sheet of 1/8” aluminum at the house. Would that be thick enough to get a 300x300 out of?

For sure!

Cast aluminum is the most stable, but anything will work fine with mesh leveling.

Ok sweet. Now just to see if I have a piece big enough in what I have left lol. I’m pretty sure I do but I’ll find out tomorrow when I finally get back in town. Thanks for the help!!

I found the best results in 300ishmm sizes by searching for cr10 beds. So it is surprising you are having trouble ![]()

There was an expensive option linked here somewhere for a taz printer. I have been dreaming of a nice AC heated bed for a while. My only current complaint on my gridbot is that I can’t probe it until the bed gets completely warm. My current bed takes too long.

I could find those with the 24v heater but I couldn’t find one without a heater or with a 120v 750w heater. I’m going to try making my own since @vicious1 says the 1/8” will be thick enough for it.

Question for you…in the cad model when I make it 300x300 the bed gets all wonky. How do I know what actual size the bed needs to be cut at? My first thought was 300x300 but then I looked at the 400 you linked and it was actual 410x410 so it made me want to make sure I cut it correctly

This is THE most frustrating thing that has my build not making progress.

If there was a reference design that used the CR10 sized build plate, I suspect that would be an enabler for a lot of builders.

I keep sitting down to figure out F360 and the customizing- because I want to learn it- but never make progress and bail out.

I have spare 24V TAZ build plates, but even there without adding some additional holes they wouldn’t be usable for me0 and even then I’d need to solve the F360 learning curve.

I understand that completely. I am “ok” at some things on fusion but I was completely lost until I made and post and @vicious1 led me in the right direction. I suggest you make a post with the problems you are having and I’m sure someone will be able to help you out and get you on your way. If the bed size is all that’s holding you up then hopefully someone will answer us here lol.

I made a reference for 200x200mm builds. There would be no editing whatsoever required if you made it the size it was designed for. Sorry, I just do not need 8 giant printers.

I also use a extremely common mk3 bed. The holes are very standard and have been around for nearly 8 years now. Every 300mm bed I have seen is a completely different size, when you can find them. For anything larger than 200 you will need to do some CAD in my designs.

The MP3DP bring in nearly zero income and is completely open source. Unfortunately, my time gets spent where my bills get paid. If you look through all the MP3DP threads the only two built alike are mine, every single other mp3dp has different size, extruder, electronics, bed, fans, leveling. This is the reason I have zero interest in being a 3D printer company. Everyone’s desires are different. So I made the printer I need, an extremely accurate workhorse, since I spent the time designing it I made the CAD freely available, but I just can’t accommodate every edit everyone wants on it. I did my best to make it as parametric as possible.

I switched from SolidWorks to Fusion 360 just so I could share the CAD openly.

Can you show me a screen show of the bed drawing and how it gets messed up? Did you change the dimensions to match your bed? Was it your thread that I asked what version of the CAD you have, are you one v31?

I apologize for tagging you so much in this thread. I guess im so used to the LR3 and Primo where you spend your time.

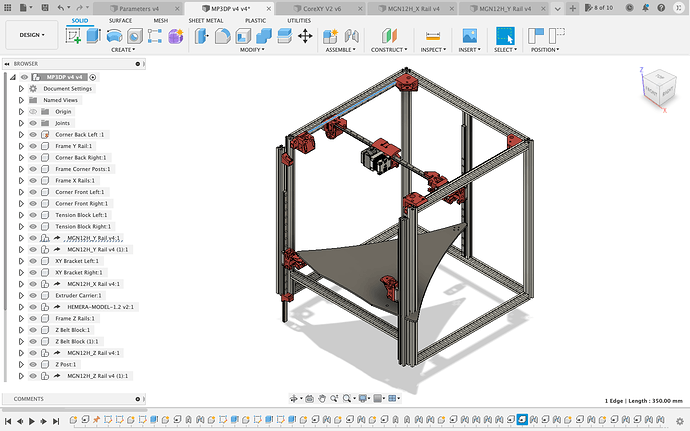

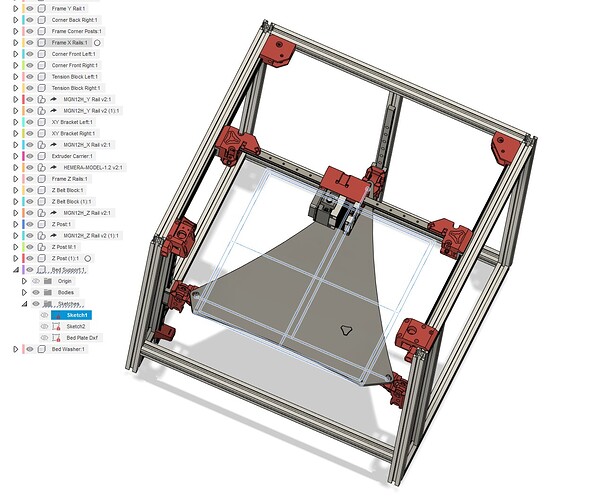

Here are the screen shots…

I dont believe it was me that you asked about version. But i am on my Mac laptop. It might work better when i get home on my windows machine. I will give that a shot and see how it goes.

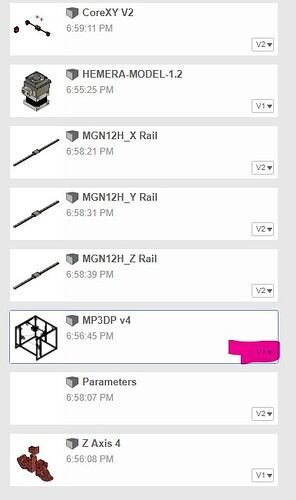

I am making a 300mm version right now. When I scaled it up the only error I am seeing is the bed mounting holes didn’t follow very well. I will post a link in just a bit.

I am looking for this version number,

For the link you currently have I am on v31, I did a bunch of minor edits. I am just not sure if the link I shared updates or is frozen on a certain revision.

This 300mm version will have a different version number, and will also not update. So for the printed parts, always go off the main 200mm version. Just use this for the bed plate and part lengths.

I took the bed plate you had modeled in the 300mm version and basically just squared it off like a normal bed plate. Im assuming I can just cut this square and also cut the holes you have and that should get me lined up where i need to be??? I will go back and radius the corners and such but wanted to make sure im at least on the right path.

Bed Plate.dxf (4.6 KB)

No, the sketch just before the bed plate is the actual bed size you need, with hole locations.

Where did the link go?..other thread…" 300mm, Fusion

You will surely need to edit the bed size and then mounting hole locations for it."

This threw me off. So i need the bed plate and that bottom support triangle out of aluminum? And what do i need to edit about the size? You blew that model up to 300x300 which is what im going for. Sorry for all the stupid questions. This is my first ever DIY printer