You need to go into the bed sketch and make sure the dimensions and hole locations match your bed. I highlighted the exact sketch to edit. In the previous post.

So if im going to make my own bed out of 1/8" aluminum i can just cut it at what you have it set at already correct? i think thats where i was getting confused. And if i am correct on that then i will need to cut both pieces correct???

Under the bed support 1 there are 3 different sketches. Do i need all 3 of those pieces cut out of aluminum?

I truly do apologize for all of these questions. I promise I am trying to follow you to the best of my ability.

The subject got smeared over two topics.

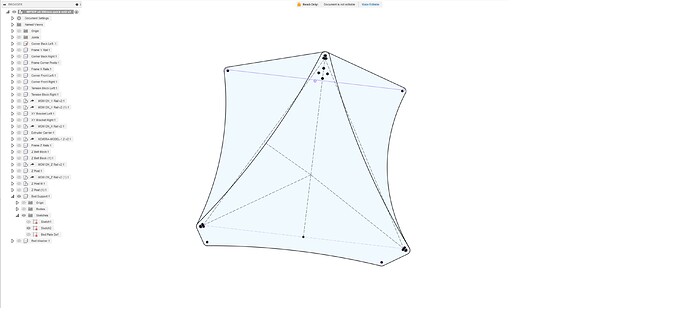

“One sketch is the bed, the next is the bed support, the third is the combo for making a DXF.”

I think if you open the sketches you will see exactly what they are. The first one is the bed, with holes. The only trick is it is offset to account for me using a hemera, if you are not using a hemera you will need to change that as well.

The very next sketch uses the previous sketch and forms the support, you should not need to touch this one.

The third sketch will be the DXF used to cut the supporting triangular plate.

Yes. The chances of it being perfectly flat are slim. It will probably have a dome shape, but as Ryan already mentioned, with mesh bed leveling technology in the picture that is not a problem.

If you do not mount it rigidly, like I mount all mine of fairly weak springs, when you heat it, it will deform considerably less than if you rigidly mount it.

Mesh leveling, compensation fade are both on by default on with the MP3DP firmware.

Sounds good. I will mount it loosely When the time comes i will be buying all the springs and steppers from you so i assume that’s the same springs you use on your printers.

I truly feel like I’m just beating a dead horse and frustrating you more and more. But this is kicking my butt for some reason. Its sketch 2 thats throwing me off. I see the build plate in sketch 1…that makes sense. I see the “triangle” part in Bed Plate DXF. But i cant understand where Sketch 2 comes in to play. If all i need is the build plate and Bed Plate then im good. I starting to think im paying attention to something i shouldnt be but im just not sure. Again im very sorry for causing a ton of frustration with this. It is not at all my intent to be a PITA.

Ok i keep looking at this and reading over everything you said trying to wrap my head around it. If i choose to run the Hemera then i should be able to save sketch 1 and 2 as DXF and cut those out to get what i need?

Does that clear it up at all?

#1 and #3

I will be out today, so if you have questions I am not ignoring you.

Perfect!!! Thank you!!!

![]()

![]() Guilty as charged. I often wonder how the printer guys who sell kits manage it, figuring that people like me build the things…

Guilty as charged. I often wonder how the printer guys who sell kits manage it, figuring that people like me build the things…

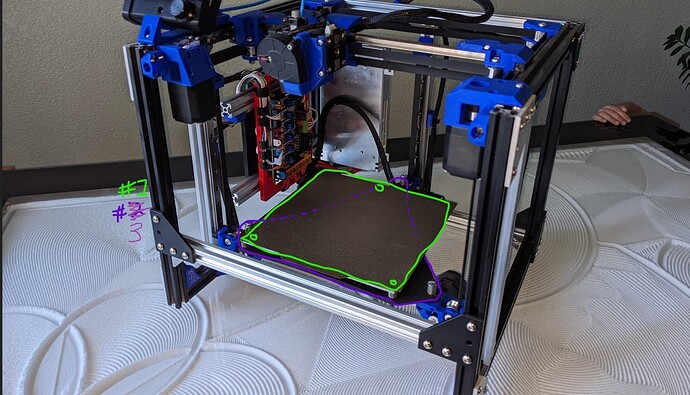

My 300mm build uses a 24V bed designed for a CR10. I had intended to make my current project “as designed” but it didn’t work out that way.

Maybe one day I will build a V1 machine unmodified…

What’s the fun in that, do it your way.

What’s the over/under on that?

Well, I suppose that my ZenXY is pretty much stock…

IDK, Ryan’s is a dining room table. So is that the standard size?

Just so Dan doesn’t have a stock one, lets say 3’x4.5’ is standard.

Gotcha!

Well no one around me has any “Cast Aluminum”. But i was able to find a 2’ x 4’ drop of 1/4" aluminum so that should be more than enough to get both parts i need and have some left over. Aluminum is NOT cheap lol. I guess nothing is anymore lol

This is what I ended up ordering for my build plate. I’m going to put a magnetic PEI sheet on top.

For the heater, I picked up a 120v 750w heater for a cr-10

Ordering SSR (solid state relay) and insulation foam for the 120vac heat pad?

Yes.

I’ll post a full bom on my build page at some point. Probably after I have it built