Well, the bleak midwinter has arrived and as promised I am starting this thread with build details on a wall mounted pen plotter I have been working on. For anyone who is interested in building one, here is a summary of the project. I recommend reading this post before you dive in. I intend to provide much more detail (in future posts) regarding parts lists, 3d printed models, hardware, software, wiring, etc., so no need to ask for that just yet. Please be patient and it will all be made available.

Summary: The build is relatively easy. It’s just like any other pen plotter out there, except it’s a lot bigger than most, its wall mounted (most sit on a table top), and it can grab pens as needed out of a tool bin. Once all the parts are in hand, it goes together nicely. The devil is in the software. Specifically, I am talking about generating the gcode to send to the thing. More on that later…

Material: With the exception of a small spring in the pen holder, the Jackpot board, and wood for the backing, everything is available on Amazon or your favorite CNC maker parts outlet. I will upload the models for all the 3d printed parts when I get a little more organized. Obviously, if you choose to build a box frame for the thing like I did, you’ll need to source that wood locally.

Electronics: V1E Jackpot board running FluidNC

Software/gcode: Here’s the rub. I’ve spent lots of time and expect to spend lots more time coding a custom interface that provides a somewhat automated process that imports pictures, converts them to lines then gcode then sends them to FluidNC with a few taps on a tablet. It will also make generative art derived from mathematical algorithms (similar to Sandify). I’m not going to make that software available (mainly because it’s highly customized and a mess right now), however, I will do my best to point anyone interested in the right direction do all that manually. Meaning, you use any number of available software programs out there (GRBL Plotter, Sandify, Plotter Fun, Drawing Bot, etc. ) to create the gcode files which you can then upload and run via the FluidNC UI. Knowledge of GRBL is required in order to integrate the tool (pen) selection code into the gcode created by the aforementioned software.

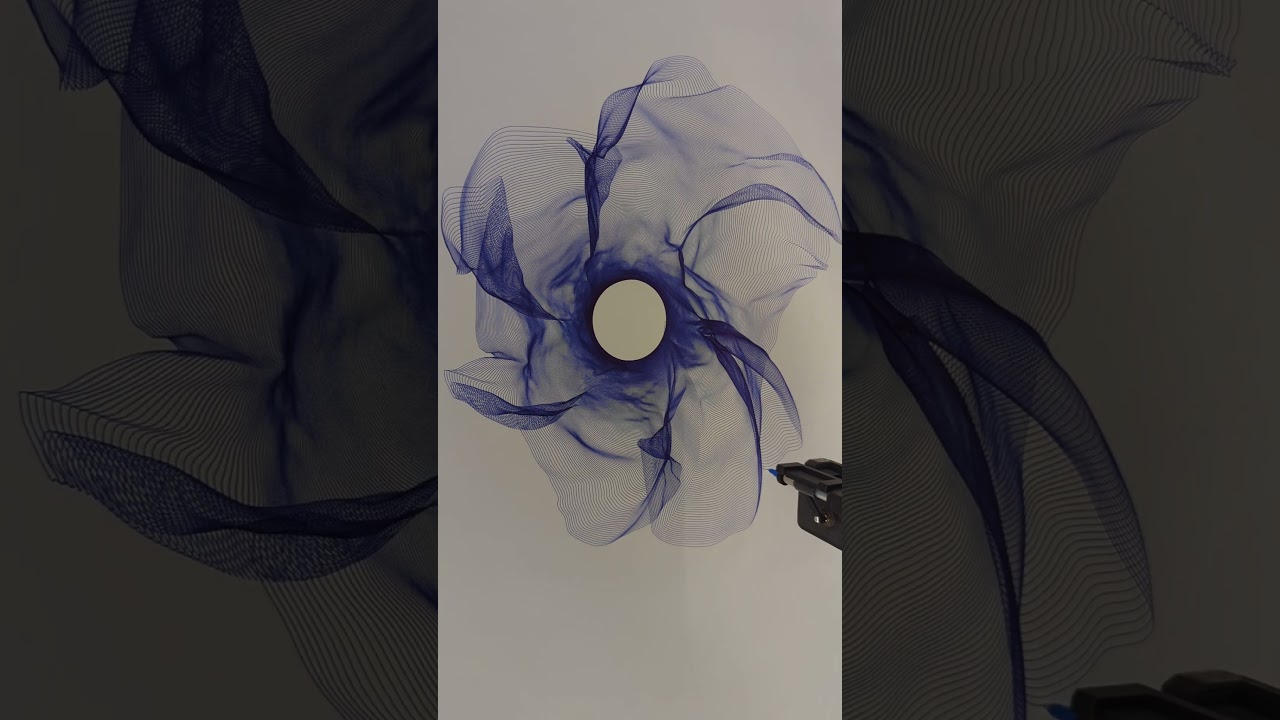

Here are some recent plots…

This is a computer generated plot from some code I wrote that was inspired from the Sandify code. It is one continuous line of 380 concentric circles, influenced by a Perlin Noise field modified exponentially by the radius. Total distance of pen travel is 1814 feet. (I will try to embed a video of the plot at the end of this post.)

(One pen, Uni-ball Power Tank, 6.5 hours)

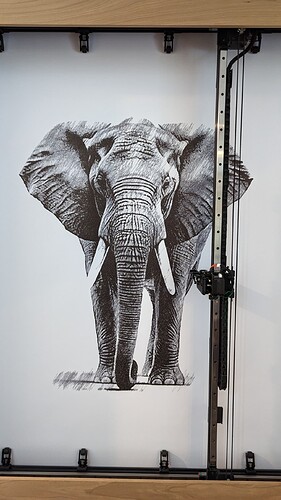

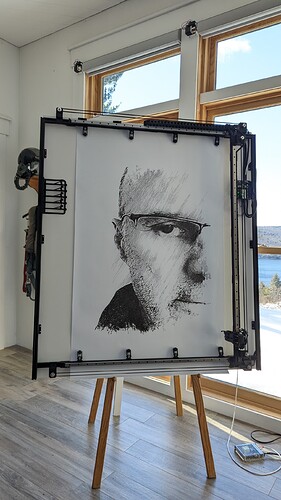

This was created by a raster image to line conversion algorithm.

(Two pens, Pigma Micron and Uni-ball Power Tank, 14 hours)

Another raster image to line conversion algorithm. This is a slightly narrower version of the original plotter. Sizing the frame is fairly easy.

(Two pens, Pigma Micron and Uni-ball Power Tank, 12 hours)

Here is a short video of part of the first plot pictured above. Watching this thing draw is as good, if not better than the finished plot. Like a ZenXY, it’s about the journey, not just the destination.

I will post the BOM, 3d printer files, build details, over the next few days/weeks.