Hey everyone, I’m relatively new to cutting aluminum with my Lowrider v4, and I just realized how exhausting it can be to constantly babysit a CNC router while using a spray bottle for coolant—especially during a one-hour cut. How would you guys recommend setting up a mist coolant system?

If you’ve got compressed air, maybe something like this:

https://www.amazon.ca/dp/B071DXGGP4

And you could automate it by adding a simple solenoid valve to your air supply.

That said, I don’t actually have any experience using a system like this so, I’ll be interested to see what other, more experienced people have to say.

Big Red had some sort of misting system I think

Most of us, including me ![]() use trochoidal cuts. Depends on what you are doing though.

use trochoidal cuts. Depends on what you are doing though.

Wait, so I don’t need coolant on trochoidal cuts.

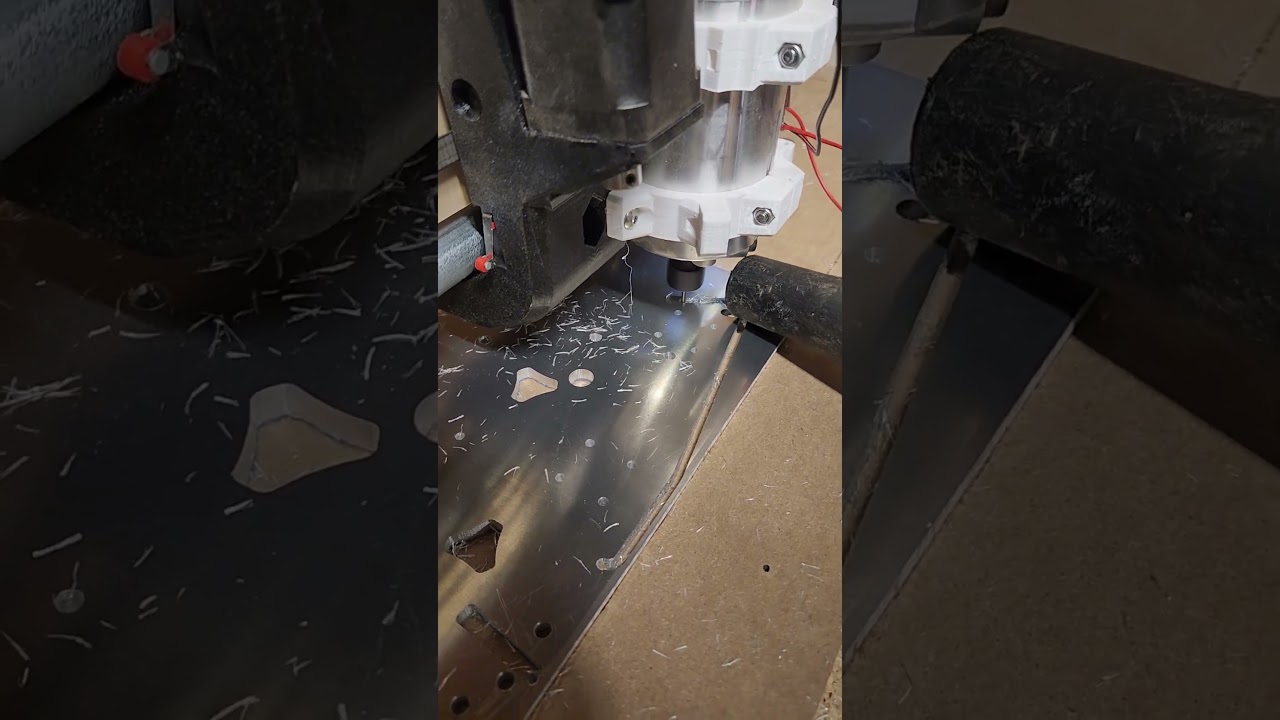

That is why it was developed. It prevent heat build by limiting engagement. Depending on what u are doing you should not. Cutting my lr4 parts went great, even though I had printed plates in!

Chip load is lower so less change of chips welding themselves to the bit.

All the cuts in the thread I linked were done with no cooling of any kind.

Oh, that makes sense! Thanks for the help!

I still used mist even when using trochoidal. I found that I was still getting some chip welding without