I built the lowrider v2 with absolutely zero experience in cnc. The build went successfully and I have the SKR withe marlin firmware. I have tried kirimoto and the results were that my machine cuts a mirrored version of the file I input. Thinking it was a communication issue between kirimoto and the SKR or marlin firmware, I tried using fusion 360. I was having trouble loading my machine into 360. I had read on one of the forums here that there was an additional post processor that I needed to download in order for 360 to be used with my setup. I did that and still no luck I’m not sure if the post processor is even loading into 360 but positive I’m not getting the machine to load. For lack of a better apparent option I am just using a generic machine option to load it. Any advice for what I am doing wrong is greatly appreciated. Thanks in advance.

Why not try the recommended estlcam? It is much easier for us to help with that. From there when you have full mastery of the software moving to a different CAM package will be much easier.

Some of the language in your post is a bit confusing.

If you really want to use kiri or fusion for CAM, you just export the file and run it with your machine, it never plugs into or gets driven by either.

Thanks, as I said I am new to this. I will try your recommendation. I understand the machine never plugs in. as I understand it to setup the file for gcode the program needs a basic understanding of what machine is being used as well as it’s feeds and speed’s capabilities and tool size. When I select the generic machine type it will not load to the setup. Therefore will not generate a file that operates on the machine.

Estlcam basics is a far easier way to start.

For Fusion 360, there is a Machine Library, and a Post Library. You can safely ignore the Machine Library. I’ve used Fusion 360 for CNC work for several years, and I’ve never defined a Machine for the Library. I didn’t even notice the lack until someone asked a question on the forum. I’m guessing that, if an accurate machine was defined, the estimated machining times would be more accurate. They can be way off, especially for adaptive clearing. But I cannot imagine the machine definition has any impact on the g-code generated.

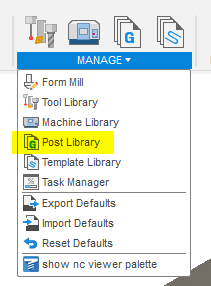

You do need a postprocessor for your machine. You will find the latest MPCNC version in this topic. Select the following menu item and use the dialog to add the postprocessor.

I second that recommendation to use ESTLcam. I started off using Easel (free version) but then switched to paid version of ESTLcam and glad I did.