Getting ready to make my first cuts in aluminum. I have lots of questions, and so far the answers seem elusive, confusing and/or contradictory.

My LR3 setup includes:

- Makita Clone 1.25 HP Router (10k-30k RPM)

- 1/8" single flute carbide upcut end mill

- Air mist with Iso-Propyl Alcohol (IPA)

Several sources on the Internet say to aim for a chip load of 0.013 - 0.030 mm/tooth for aluminum, so that is what I will be trying to shoot for.

I’m going to be doing pretty much 100% slot cutting, and was planning a single roughing cut, with a finishing cut of around 0.32 mm (10% of tool diameter)

The material is 2mm aluminum sheet (I think it is 5052-H38, but not 100% certain). I have read that 5052 is exceptionally “gummy”, so I was thinking to use trochoidal milling.

Everything that I read about trochoidal milling seems to state that the concept is you decrease the Radial DOC and increase the Axial DOC. Because the stock is so thin (2mm), I can’t really increase RDOC very much, so I’m not sure if trochoidal makes sense in this particular case…

So question #1 - for this relatively thin stock, should I just use regular climb milling, or should I use trochoidal climb milling to avoid gumming up the mill?

I’m using G-Wizard to assist with selecting feeds and speeds, and I’m using EstlCAM to create the toolpaths.

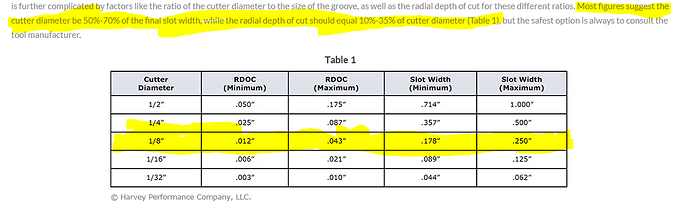

Conundrum #2 - One site on the web (Harvey Tools) shows slot width as 1.43 to 2 x tool diameter (tool dia / 50%-70%), or 0.178-0.250" EstlCAM on the other hand suggests slot width as 1.25-1.50 x tool diameter (edited)

I understand that a wider slot width allows for better chip clearing (less recutting), and more time without tool contact (more cooling), at the cost of an increased overall time requirements. I don’t mind a bit of extra cutting tiime, but I also don’t want it to end up being a 10 hour job.

So question #2 - is EstlCAM’s narrower slot width suggestions appropriate, or should I go with Harvey Tools’ wider slot width?

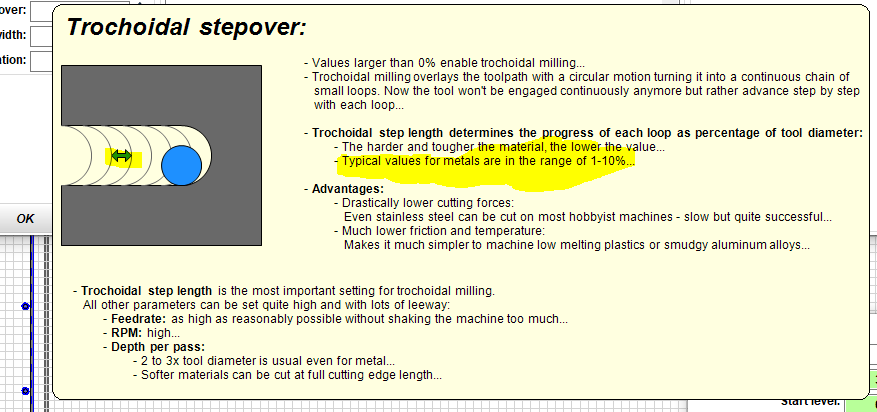

Conundrum #3 - EstlCAM recommends a “Trochoidal stepover” of 1%-10% of tool diameter (0.00125 - 0.0125"), while Harvey Tools (above) recommends a RDOC of 10-35% of tool diameter (0.012" - 0.043").

I’m assuming that stepover and RDOC are the same thing, but EstlCAM’s suggestions seem incredibly small (just over one thousands of an inch DOC??? Wouldn’t this just be rubbing?), unless the feedrate was VERY fast (probably beyond the LR3 limits)

So question #3 - what is a realistic value to enter into G-Wizard for Cut Width (Stepover), and into EstlCAM for Trochoidal stepover?

One final conundrum (and question #4) - for a fairly shallow cut (2mm) into a fairly soft material, do I need to ramp or helix the entry, or can I do a straight plunge (and what feed rate should I use for the Z axis to do the entry).