There is plenty of knowledge here about trochoidal milling. Many of us have used it several times. Maybe not for steel. But I do know that using that many flutes at that high of RPM is going to create WAY too much heat for just air cooling and a little wd40. That more than flood cooling could deal with possibly. You have to take into account that 99% of the info out there for milling steel is with MUCH slower spindle speeds. Around 4k rpms or less

AI will also not be helpful here.

For it to have any shot, it is going to have to have a huge amount of detail about the makeup of your machine… and even then, it is going to understand the industrial CNC world much better than the hobby CNC world.

IF there is little knowledge about the subject, then the AI can’t have the right answer. It only knows what is already known.

It is spitting out what it’s “brain” is saying is the most logical set of words to return to you based on your input, but it is programmed to give “an answer” no matter what, not to say “I don’t know”

Most of the info I have found from machine and tool sites, not AI.

I used AI to get some settings, but as I wondered about the high speeds given I thought I would ask here. Maybe my mistake, as I am using steel as the material, not wood or aluminium.

I dont think it was a mistake to ask. Everyone is trying to be helpful. Anything you look at online for milling steel is going to assume a much slower spindle speed. That’s where the problem comes in.

Looking back at your settings in your first post, I think your trochoidal stepover is way too high. Going from Memory I think that’s more than I run in aluminum. Yes making that lower will make the cut take longer, but it should give you a better success rate as well. My suggestion would be to bring that down to 5% or less, and if that goes well, step up slowly from there, say 1% at a time until you start to see issues.

If you plan to stick with the 4 flute endmill I would make sure you have your spindle going as slow as you can. That will help with heat as well.

Thank you Jonathon, these are the sort of answers I was looking for. I will reduce the stepover a lot and see what I get in virtual mode, not game to try out for real as I am down on cutters now.

I stayed with the 4 flute carbide endmill as it was all I have left. Reduced the stepover as suggested, kept everything else the same.

Was a fast milling operation, it surprised me.

Came out pretty good in my view, 8mm thick mild steel.

Really nice, that’s a success! ![]()

And now you are going to tell us about the settings, right? ![]() In case someone else wants to try it.

In case someone else wants to try it.

settings are at start of post, just changed the stepover to 4%, big change,

So the 3mm T?

I am still testing. The tool had very little clearance and I had to constantly flush the chips from the cut.

I will increase the trochoidal width to give more clearance, maybe as much as 50%

Ok, Ryan just posted a website for speeds and feeds. I wonder what that would say. You can choose genmitsu 3018. You do need a user/ pw to use it though!

Any further info on that website? I can’t find any reference to it here.

Tried it out, could be useful for a few things, but doesn’t cover trochoidal milling or steel as the material.

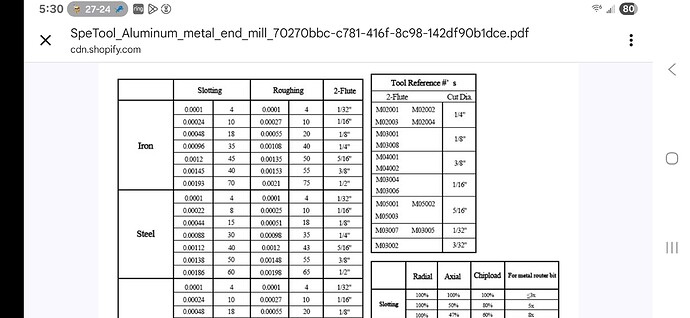

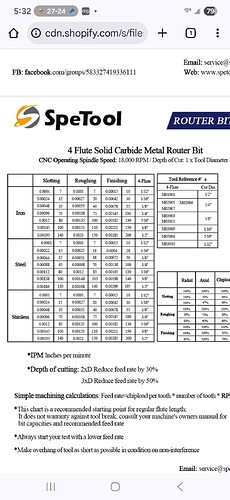

Here is another site that also doesn’t cover enough, but is also very useful.

Great, I will check that out.

I did find that my settings need a change, I noticed in the last test that the ramp in is not a good idea with trochoidal, a lot of sparks were give off until it got into the main cutting routine.

I flooded it with soluble oil and water during that start, because it looked like there would be some problem. All went fine as soon as it left the ramping section. I think in future I would drill a hole for the start and have the tool go to the bottom and start in full trochoidal mode (turn the ramping off and give the tool only say 0.5mm to travel down to save time.

Changed a few more settings, still not 100% happy yet, but hell, trochoidal is very fast compared to conventional milling.

Very cool. Please consider posting your sucess in the Things you’ve made section so they get added to the gallery.

8mm steel, that’s really impressive.

Please note that I have a very rigid machine, all metal construction, ballscrews and large linear rails.

The steppers are geared down with belts to give more power, and have a 2.2kw spindle with VFD control. Not all machines could handle these settings that I have been using.

I think that information would have been very helpful to include in your original post. You might have gotten different initial responses.

I, and maybe others, assumed you were either using a MPCNC or Lowrider