That sounds pretty great! And dinner on a boat sounds lovely. ![]()

I bet @bitingmidge can give you some tips, he’s got a boat as well, with some grade A decoration my kids made… ![]()

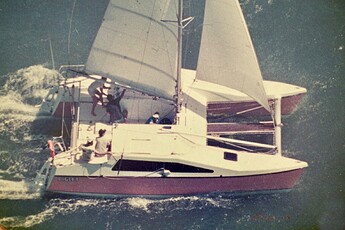

Who started talking boats? ![]() That’s just an open invitation for a hijack.

That’s just an open invitation for a hijack.

Great plan!

We have a rolling 13 year plan, which is possibly a bit like yours but we’ll get there sooner! ![]()

We had ours when the kids were still young, pretty much sold it to pay school fees, but one of us didn’t relish the thought of crossing oceans anyway, so a new 13 year plan was born!

Yeah well, I sent a bulk email to all of our kids that said they were to do nothing that would give rise to giving birth to a child between June and September in any given year, then set the next 13 year plan in place which involved flying across oceans and living for five to six months on our boat somewhere in EU. (Subsequently every one of them had at least one child in that timeframe.)

We’re now 16 years into that plan and it seems to be working, except that after visiting our now 6 grandchildren and cleaning up the mess that absence creates, there is little hobby time left. Security on the boat is helped along by a pink handled, lethal wooden shank that is meant for killing dragons, but would scare burglars in a pinch, mounted just above our companionway - thanks to the generosity of @Tokoloshe 's clever kids!

Every thread is a boat thread if we wait long enough! ![]()

Exactly! Id post my boat but its all work and no fun lol

where does the time go guys?

Been a summer of trips, birthdays, pool parties, and prepping to move 3 kids to a brand new (sex predator free) school across town, plus commissions and shop work. My hospital contract came to an end, but i picked up 4 clients that required CNC work, and the LR3 just kept rolling along.

However- as we grow bigger as a company, and I feel more and more external clutter clogging my brain, a few weeks ago I decided to revamp the shop and get more efficiency. That meant finally finishing the shop organisation projects, buying my final big tool - a supermax 1632 drum sander- and getting rid of all tyhe clutter. And finally start my youtube channel- which i keep putting off because the shop never looks as good as it could.

To that end- I made a bank of drawers - all hardware-less, using wood runners, saving hundreds of $$- made a drill press table, organised my tool wall… and started the LR4 prints. Two pieces, anyway. the little collar things that were recommended to print as test pieces.

Ive also decided to make the LR4 smaller format. 40"x 40" footprint. so whatever will fiot in there. Other than the struts i never installed, I never used more than half the bed of the LR3, so i had a whole 52"x36" section at the back that just collected clutter. So this downsize- but upgrade at the same time- will add capability, add storage, reduce clutter and allow processes in the shop to flow better.

If i ever need a larger format, i can throw some plywood down on a platform in my garage and convert the LR4 temporarily, or just never get myself into a situation requiring a bigger format, lol. Probably easier.

Anyway, some pics-

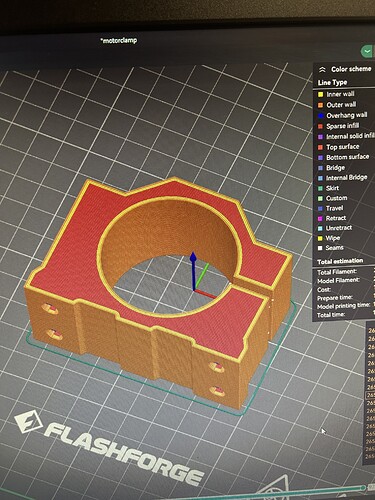

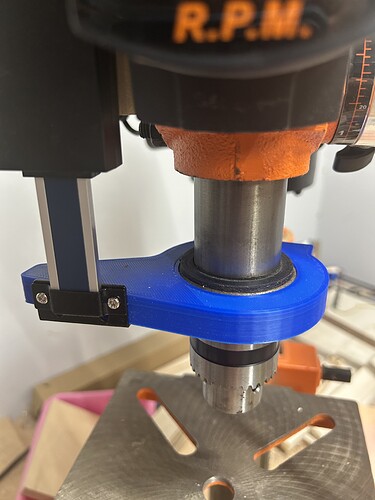

Also been 3D printing on the “new” flashforge I got with @DougJoseph recommendation.

Dust collection adapters, a digital readout bracket for my drill press, storage, a motor clamp for the motorized drill press table… lots of fun stuff

So, right now, the LR3 is on sabbatical, and I’m going to plan the LR4 prints and the table for it.

I really like the idea of a vacuum hold down, but may go with dovetail tracks and clamps, or I might go with dogholes, pvc pipe stubs and cam clamps

Man, those drawers are as simple as they are great…

and man, I’ve had that on my wishlist forever… Lucky you!

Best part- all drawers are based on 3” or multiples height. So any drawer can go in any location if I decide to move them around. I’m going to standardize the size and spacing across the drill press table and the under Cnc storage too. Max flexibility

And yeah- that drum sander is awesome. Been after it for 18 months and I finally got a client that justified the purchase .

He gave me 4 16/4 x 9 x 72” paulownia boards and asked me to make 1/4” thick panels to make a surfboard. Fun week.

Used the bandsaw to resaw, drum sander to smooth cut faces.

That push thingy is nice. I have the most problems resawing that the cut wanders because I can’t pressure it equally, my table does not have a slit though. Might need to figure something out. Those cuts look pristine. ![]()

YES!!

Agreed, I might give it a shot on my full Sheet LR build. The big table has lots of room, a few drawers would be nice.

The softwood definitely helped, but I spent a solid 4 hours setting the bandsaw up when I first got it. ZERO drift in the blade, it’s perfect. Helps that I got a dedicated 3/4” resaw king blade, low tooth count, big gullets, it just goodies like it’s cutting low fat spread (not allowed bitter, doctors orders).

Yay, that Dude has spoken, I’ll get those going poste haste

Look up mag switches. Super strong switchable magnetic that can be used for jigs . You should be able to make a feather board that sticks to your surface assuming it’s cast iron

Yes. I can’t lift it by myself. I mean, I did once but that was accidentally and it wasn’t pretty. ![]()