So, sadly, it happened.

Picked up a quick 90 minute job on the 22nd machining a bunch of recesses in 6 pine boards supplied by a customer. Rough pocket with a 1/4” bit, clean up with a 1/8th. Easy right? Quoted 125 for the job, guy paid 150 with a tip.

I’m 4 minutes in, and the grain splits, and wedges a 5” long, 1/4” wide splinter wedged itself between the edge of the piece and the dust shroud. Torquing the core and cracking the lower portion near one of the lower bearings.

So, i put the LR3 aside, and laser cut a router template using the 80w, in order to get the job done. what was quoted out as an hour total, now took 4 hours, and included additional material costs and machine time. Anyway, Parts delivered two days later, happy client, sad small business owner.

Now, onto the LR3. I’m still 40 units short of completing my Hospital Awards plaque order. Heres the kicker- they like them so much, they started giving out 2 a month… without telling me. So, they are running out, didn’t update me with the timeline, and now I had a week to get them 5 units to get them through January 25.

So- I filled as much of the core crack as I could with medium set superglue, but i couldnt torque down the bearing bolt to keep the core snug to the rails, so whenever i had a plunge, the core would visibly lift and go off target. sacrificial test pieces for the win. So, as an interim solution, I used layers of blue tape to increase the apparent diameter of the bottom conduit tube until the effect stopped, dropped down my feeds and changed my machining toolpaths (lead-ins and offset pockets) and was able to bang out 7 plaques in 2 “SAHD-with-kids-on-vacation” workdays. Frankly, some of the cleanest pocket carves I’ve done. Laser engraving and finishing, then delivered to a happy client, who apologized profusely for the lack of comms regarding stocks and replenishment.

While i was lasering those, i pulled my 6 year old adimlab gantry 3d printer out of the backroom, since i need a new core. set it up in the wood storage area, flipped the switch- nada. zilch. nothing. Thing doesnt switch on. I throw a quick email to the facebook support group- which bounces, because the group no longer exists. Uh oh. Im SOL. Old printer, no support…

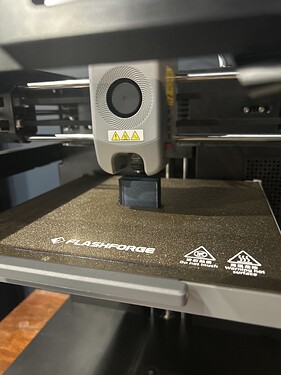

I go to my Amazon and pull the trigger on the Flashforge Adventure 5 thats been in my cart for 3 months. I put it in there after seeing @DougJoseph posting about this printer and its suitability for making th LR4 parts, after seeing that my slicer of choice (Cura) was maybe going to give me issues. I went down his rabbit hole and put it in the cart for when the time came to make my LR4 parts.

Ordered on the 26th, delivered on the 28th, unboxed on the 29th, and doing my first test prints this morning.

I will say, if the claims of hgh speed hold up, im going from 30mm/s on my old printer to around 250mm/s on this one, so my prints should be appreciably faster. I put the LR3 core into the Orcaslicer, and it spat out 5h 22 minutes, compared to the core in the Cura, at 29hours, 48 minutes. Thing is- thats at a 0.32 layer height, which the Orca cant do. It was run at 0.2mm. So i get almost twice the quality, with a 1/6th build time.

In the time it took me to write this post, the FlashForge built this cute little burnt titanium Benchy, in 13 minutes and 9 seconds. My old printer took 1 hour 40 minutes to make the same benchy, 6 years ago, on christmas day, on the dining table, annoying the wife.