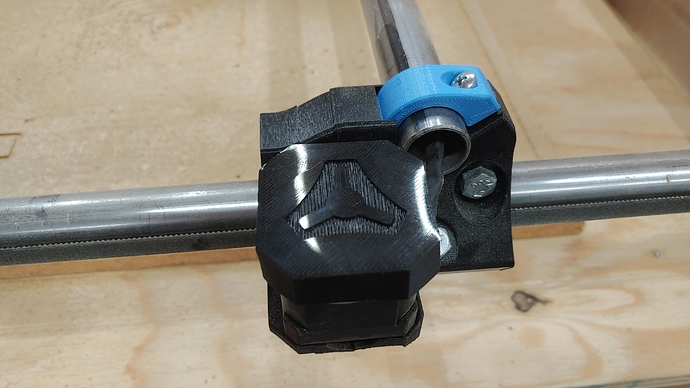

Made a little cover for the stepper motors. Hope @vicious1 doesn’t mind his logo on it.

I’m planning on putting a heat sink in mine. Might be something you wanna consider.

Mine don’t get hot enough to need them. Even the burly ran nice and cool. The only time I had hot steppers was when my ramps was miss configured. No issues with the mini rambo.

I love that we are now at a point that the 660 notices we are using it. I freaking love hearing the RPM take a little hit.

LOVE IT!

Glad to see it is doing very well now.

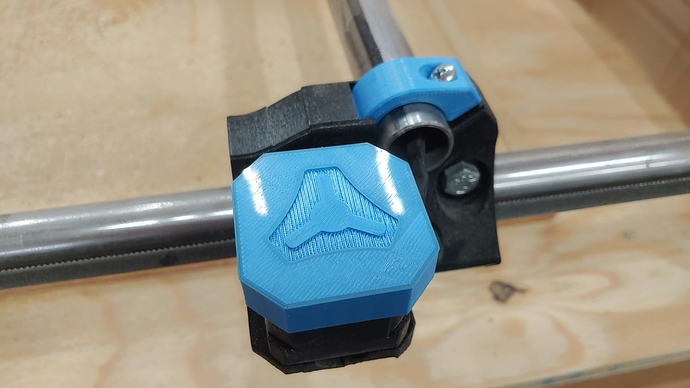

Stepper motor covers are done.

I have just enough blue to print a few of them, but at least 1 will be black.

I created a second design that has the logo open so that heat can escape if need be.

Looks like you uploaded the GCODE file for the vented version instead of the STL.

Gah

Thanks

I blame that on Chrome. The file is clearly the STL file in that directory, but I had just uploaded the gcode file to the printer. I think Chrome is having a bad time with uploads caching or buffering.

They look great. Have the 3D printer kicking out 5 of them now in a two tone color scheme to match the rest of the printer.

Let me know if they don’t fit your steppers for some reason. They took a few tries to get them to friction fit onto mine.

I need to figure out what I want to hit the Primo with… I just finished re-tightening the spindle to the Z axis during lunch and putting the 1/8" bit back on it. I think I might just try to route the V1 Logo into something.

I’ve been watching the AQUACERAS computer build on youtube and that has me itching to try and do some aluminum.

I also bought a 30A 1-channel relay I want to wire to the spindle on/off at some point.

Just finished and they are all loose. Seems have a mm or so of slop in both directions. I’m going to have to think about how I can account for that. Blue tape on the inside maybe?

Electrical tape on the stepper motor. I’ve noticed that even though NEMA17 is a standard, that sometimes the stepper cases/connectors are slightly different.

You could also try printing one at 99% and see if that fits more snuggly.

Not even finished building/testing the thing and already looking to upgrades…

Just ordered some 1/4-20 threaded inserts. I’m going to drill holes in the spoilboard for them and then cut out some cam locks. I have quite a bit of 3/4" plywood laying around after a recent project. I think I’ll cut the cam locks out of that.

The mounting holes are a standard, after that it’s the wild west.

Curious about the cam locks you’re planning. Are you talking about the hornberger style clamps.

I am interested in those as well but he uses just round holes with pegs. IMHO Perfect use for leftover tubing or old conduit from a previous build. Why the threaded inserts?

I have also bought threaded inserts for a spoil board. But now I’m rethinking that since I discovered the cam lock mechanism

Yes. I am using the hornberger style, but I threw them into f360 and filled in the holes for 1/4" hardware. My reason for using the threaded inserts is because sometimes I want to just bolt the stock direct to the spoil board. Like when I cut 1/4" plywood cutouts for my wife.

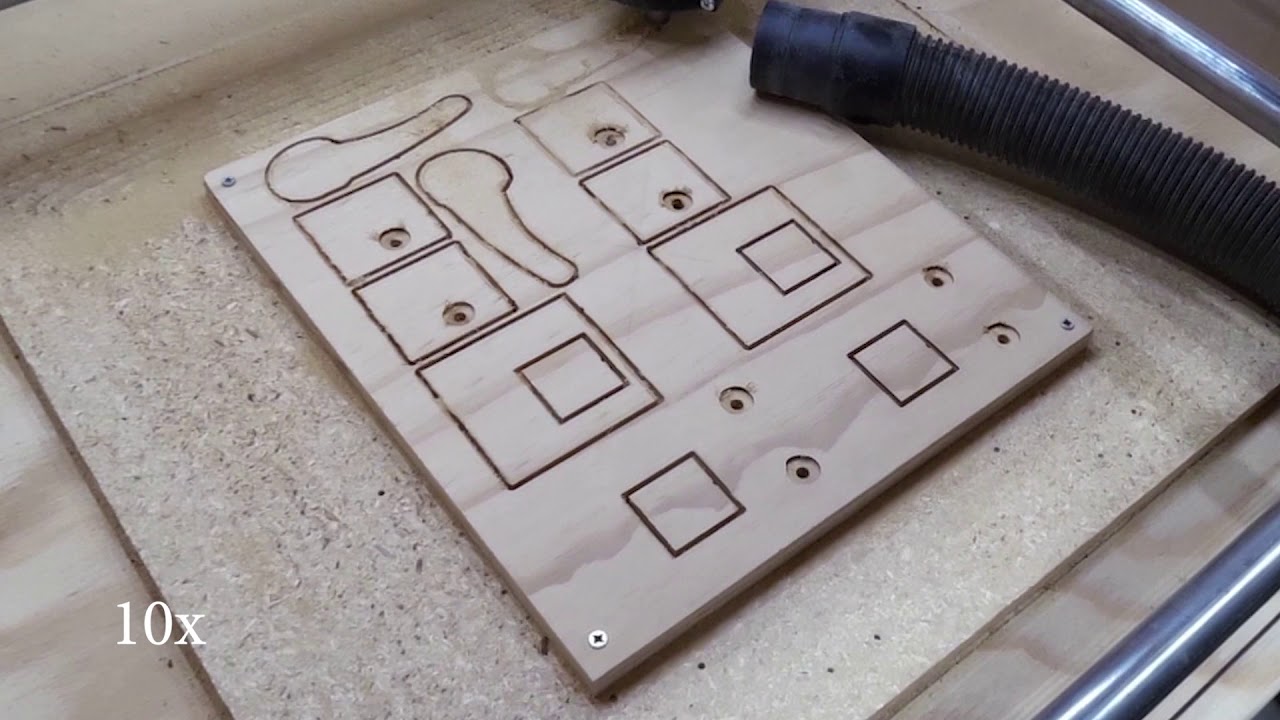

I cut the parts out tonight. Took 1 hour. Listening to the machine, I could have easily gone faster or deeper. I kept this cut with the same settings as burly. Cutting plywood, I would have had some chatter at these speeds with burly. Primo didn’t have any.

Played around with some test cuts…

7.62mm DOC at 1000 mm/min adaptive cut in pine went pretty good.

12.7mm DOC at 400 mm/min contour cut in pine went horrible. (I didn’t think this would succeed) This DOC was actually by accident. I meant to only do 7.62mm like the adaptive cut.

Is that particle board your using for your spoil board? I’m not this close to finishing but was thinking of using MDF but particle board is cheaper and I will go that route if it works just as well

Use MDF…

This particle board spoilboard is the original one that I used 2 years ago when building the first MPCNC. I’ve usually needed more height and typically have another piece of MDF on top of it. I just keep shaving it down every 6 months or so 1mm at a time. It started off 3/4" and is probably around 1/2" now

The particle board chips easy and I’ve had screws pull out. MDF also cuts cleaner.

I have two pieces of MDF that I could have used instead of this, but they were further across the shop and I was lazy.