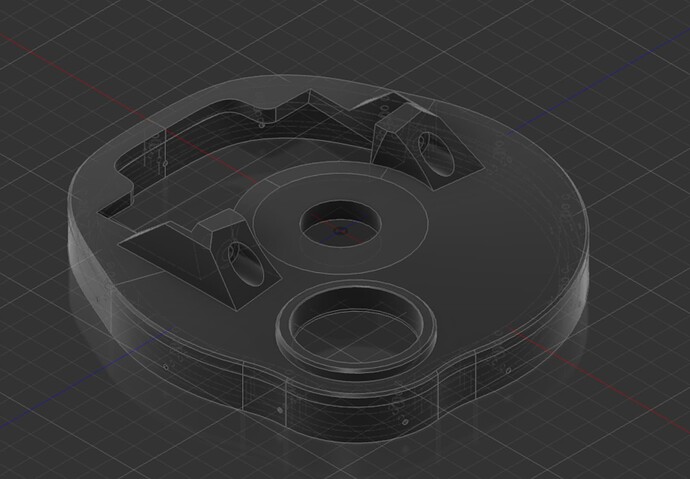

OK so the dust shoe came out of the printer. There were some minor issues, but I was able to assemble and test it today.

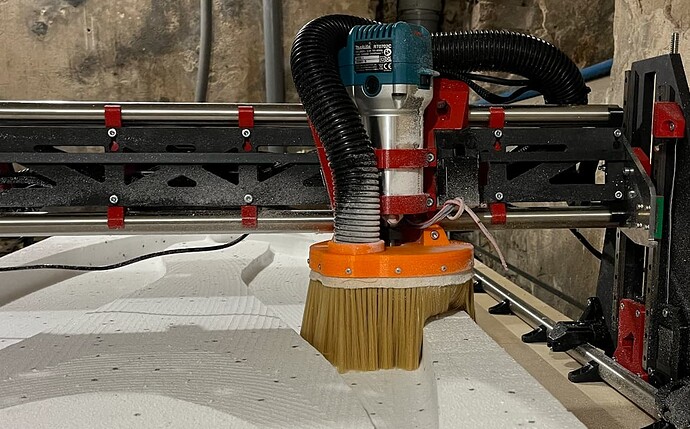

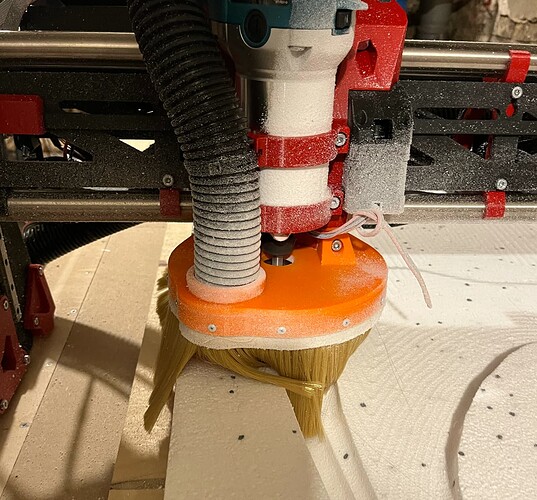

Long story short: it works ) There is probably 85-90% less dust with the dust shoe compared to me standing with the vac hose and following the endmill all the time. And now I can drink beer while it’s cutting! So it’s a win-win.

The Makita also seems to be nicer than the chinese 500w spindle. While the chinese spindle is quieter while not loaded, makita seems to be quieter when cutting. This is probably related to higher rpms. Overall it’s good. The makita is also a bit shorter, so I had to add an extension:

I’ll need to trim that extension a bit later.

The powder accumulation on the X rail is 90% solved. During 1.5 hours of cutting, I did pause the job 3 times to clean things up a bit. It would have probably been OK to let it run all the way to the end, but I wanted to keep things tidy.

I would probably benefit from a secondary cyclone, as the vac filter is getting clogged with the powder after 20-30 or so minutes of cutting so I need to empty it quite often.

Now the not so exciting news. After 2 roughing passes, the stock looked like this:

To me it looked pretty sweet at the time, except… that bump on the tail shouldn’t be there. The problem is that the entire cut is about 15mm too low. There can probably be too reasons for this: either I miscalculated Z height being in a hurry, or some steps were skipped during the cut. I am kinda leaning more towards the 2nd option.

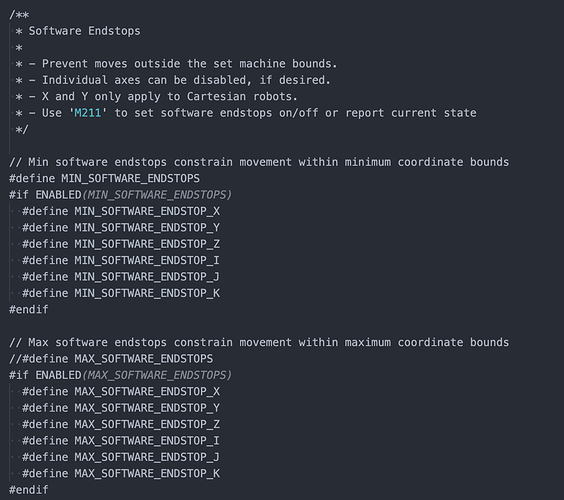

Why would there be skipped steps on the way up? I had this happen with my plywood cuts a few times as well, but usually just 1-2 mm or so. Honestly at this time I have no idea. If I’m right about the skipped steps, I could benefit from “crash detection” feature that prusa printers have. I wonder if that is a built in marlin feature or a prusa thing. Will need to research a bit more.

Maybe related: the Z movement is a bit jerky every once in a while on the way down. I think this is caused by backlash in combination with spring couplers. Usually it’s moving smoothly, but I think there is a certain speed where it starts oscilating.

I ordered 2 start leadscrews and will give them a try.

Some pics of the dust shoe in action: