As with most things in life, there is no one “correct” answer. It may end up being a trade off based on weight, strength, ease of construction, material availability, other uses for the table (like using it as a workbench), etc.

Skin at least one full side, for sure, and possibly both. Leaving the edges unconnected will allow for twist and unwanted movement (IMO)

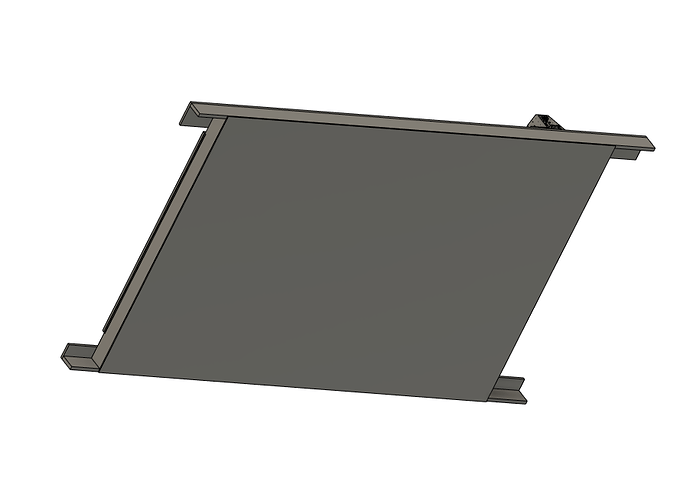

Doug’s idea of skinning both sides with a thin skin and adding a spoil board does have a lot of merit, in that it creates the “torsion” model that adds a lot of rigidity in various axis. It is also quite light. It does require some thought as to how to attach legs without cutting away the skin

My idea of using a thicker skin on the top surface only is possibly less rigid in all directions, but may have enough strength in the thicker layer to compensate for that (or not - I’m not an engineer, just a bloke with a very limited bit of carpentry experience). It does have the benefit of simplicity to build, a good strong surface to attach hold down screws to, and keeps the bottom available to attach legs to in areas other than the perimeter edges. I also plan to use the table as a work platform for building and assembling various carpentry projects, so I need a good solid surface that can withstand some punishment.

What is right for you? Possibly one, or the other, or neither.

As far as the tabs or extensions for the rollers, as long as the frame is fully attached to the skin, you should be able to just add boards on the outside and top of the frame as you have shown (as long as they don’t extend too far without support).

As far as orientation of the skin, I would try to keep the seams to a minimum, which would mean placing the full sheet lengthwise on the frame against one edge, then applying a full length narrow strip against the open edge, and another single piece at the end (again, see the pictures in my post above). If you skin both top and bottom, stagger the seams so they aren’t in the same location both top and bottom (seams are the weak point, so don’t have them at the same location on both surfaces).

Good luck on your table ideas!