Sorry about the delay but I went on vacation and then the software portion of this build threw me for a loop, a wild goose chase and then some other odd colloquialisms.

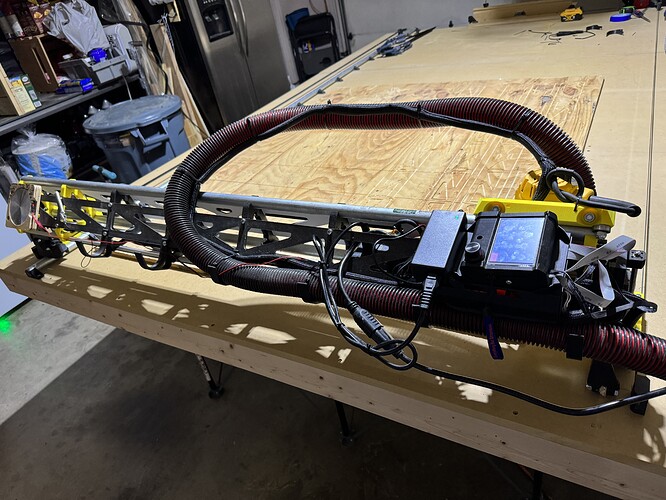

I had to figure out the post processor situation for Fusion 360 and then ended up modifying the MPCNC post-processor config heavily to make if work with my configuration.

I installed an IoT relay switch to power on the router and dust collector electronically via M106/M107 fan control. Also, my board wouldn’t let me use Fan2. After some thorough testing, only Fan0 responds to the M106/M107 commands and polarity was a fun issue when connecting it to the IoT…

I also installed the Z-axis probe with touch plate sensor and had to work out that G38.2 is the correct command for me…

Then I had to work out that my LowRider build only has 80 mm of Z-axis range, so a Z40 tool change command when using a 20 mm waste board and 20 mm work piece just pegs the Z-axis out every time…

The rest is just my inexperience with Fusion 360’s CAM software settings and getting the orientation and start points set right and not trying to drive the gantry off the top of the table.

As you can see, it’s alive! At least for the purposes of clearing a test pocket.

The one thing I can’t figure out is the M0 messaging. I spent a lot of time working on the configuration of the post processor to make sure I could give myself useful instructions at the TFT screen instead of having to remember all the parameters like the work piece minimum size, orientation and desired milling tool.

; *** START begin ***

; Set Absolute Positioning

; Units = mm

; Disable stepper timeout

; Set current position to 0,0,0

G90

G21

M84 S0

G92 X0 Y0 Z0

; COMMAND_TOOL_MEASURE

; Probe to Zero Z

; Ask User to Attach the Z Probe

; Do Probing

; Set Z to probe thickness: Z0.5

; Retract the tool to 20

; Ask User to Remove the Z Probe

M0 Load tool: 1/4" Flat End Mill and attach ZProbe

G38.2 F100 Z-50

G92 Z0.5

G0 Z20 F300

M400

M0 Detach ZProbe

; *** START end ***

;

; *** SECTION begin ***

; X Min: 83.197 - X Max: 551.806

; Y Min: 233.39 - Y Max: 484.525

; Z Min: -19.05 - Z Max: 15

; Table Pockets - Milling - Tool: 11 - flat end mill

; COMMAND_START_SPINDLE

; COMMAND_SPINDLE_CLOCKWISE

M106

; COMMAND_COOLANT_ON

; >>> WARNING: No matching Coolant channel : Air requested

M117 Table Pockets

; MOVEMENT_CUTTING

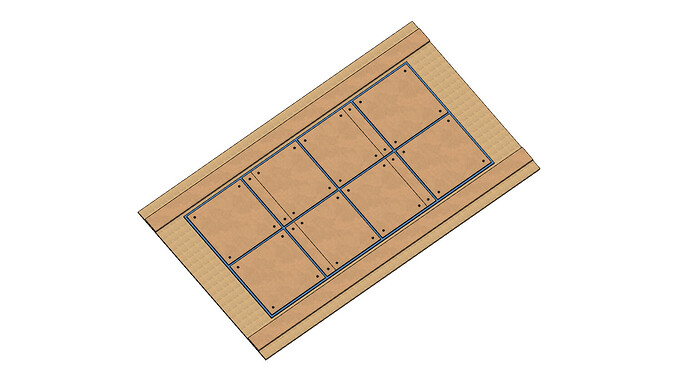

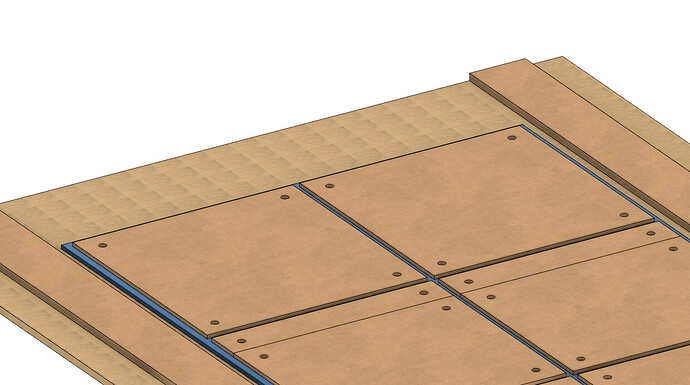

Instead, all I get is a pause screen and a resume button that really gives me no instruction. If I didn’t know a Z-probe action was the first thing it was supposed to do, I would have no clue until it started slowly dropping the Z-axis or kicked on the router…. I’ve heard Marlin mode or an M117 lcd message might be the right direction and I guess that’s up next once I get my start plates cut and installed.