A smarter man than me might have just used a 16mm top skin like he did last time, and wouldn’t keep second guessing himself.

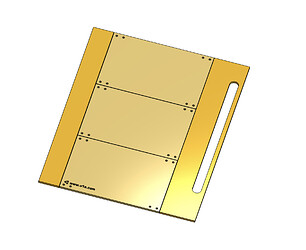

I had planned to simply double up the cross beams at 500mm centres to give myself a bit of screwing leeway for the spoil board(s), but realistically screwing into the end of MDF is not something you want to do too often and a near miss will result in a certain split. So gluing little landing pieces in was a relaxing way of filling in a small amount of time followed by a lengthy wait for the glue to dry.

I do have a plan at the back of my head - can’t be sure if I proceed or not, because all that is sensible says “just use screws”, but there’s a not a lot about this build that smacks of taking the easy way out.

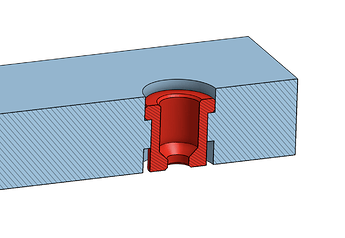

So the concept, if indeed I proceed once the machine is up and running, is to use printed grommets which will lie about 2mm below the surface, that carry screws ten or twelve mm down, and hold into a stepped recess cut symmetrically, so the board can be flipped. All boards are exactly the same size, and like many things on this build, if I proceed this will be more in the name of art than speed of construction.

Happy to hear suggestions and criticism on this one particularly!!