Today, I downloaded the Strut Plate .SVG file from the Calculator and used the ($10 for a lifetime licence) Vector Convertor for MacOS to create a .DWG file that I could upload to Onshape, my free CAD software of choice.

The following will be of no interest to anyone proficient in CAD, but perhaps might solve a problem for someone.

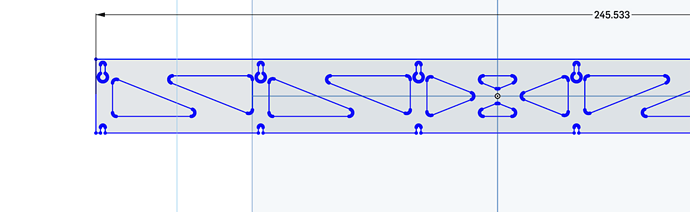

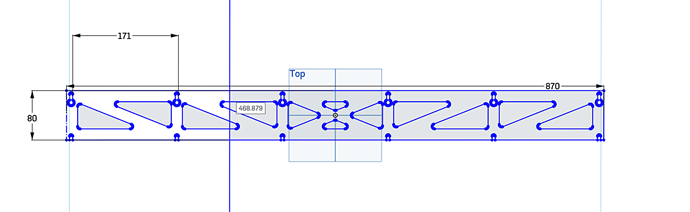

A .DWG or .DXF file is a beautiful thing as it can be scaled by the addition of just one dimension (as long as there are no others on the drawing) so I thought I’d run a dimension on the long edge to check it for accuracy. Just as well, as it was pretty clear that we have lost something in the translation!

PLEASE NOTE - THERE IS NOTHING WRONG WITH THE .SVG FILE AS DOWNLOADED - This error was induced by something I did.

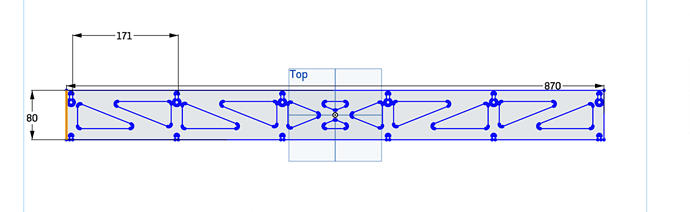

It’s not a big deal though, first dimension the “870” to scale up the drawing. Then check the height “80” which is probably correct, then the spacing “171” which is considerably less than 200 maximum recommended and therefore confirms the drawing was correct in the first place.

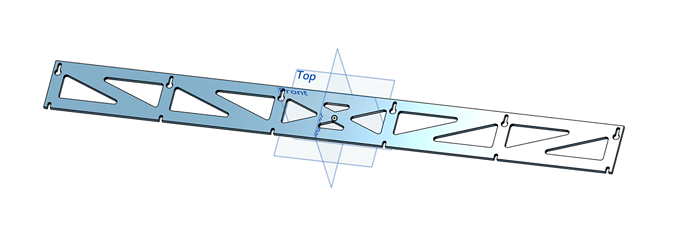

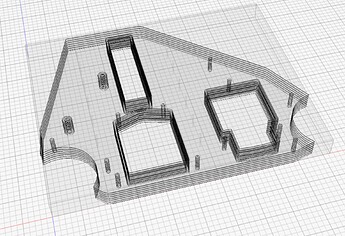

At this point I should have left well alone, but thought I’d check the web dimension and discovered that one or two lines were out of parallel by seven decimal places of a degree, so I quickly hit the “make them parallel” tool and extruded the drawing and in doing so discovered my mistake.

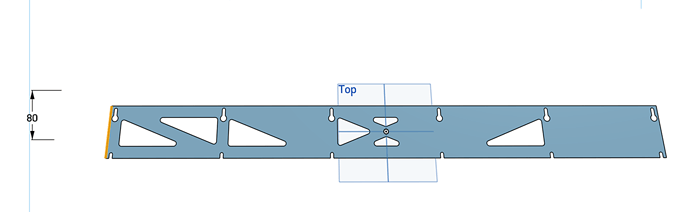

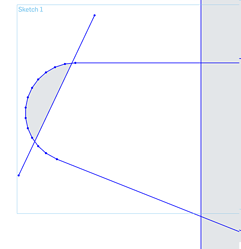

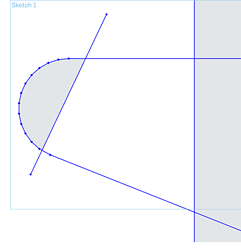

For those with little CAD experience, here’s a really quick way of determining which of your vertices aren’t closing. First - we know the bounding box is closing as it is greyed out, (and it extrudes well) so convert one of the perimeter lines to a construction line to open the bounding box. (in this case the far left)

It’s now pretty clear which shapes have a problem, and I’m pretty sure that it’s in the corners where I’ve fractionally adjusted the lines, so I simply draw a line through the first shape to find the broken corner by a process of elimination.

It’s pretty easy to spot, but even at a huge scale not so easy to see the disconnect. With a second line just move it along each joint until the “leak” is eliminated.

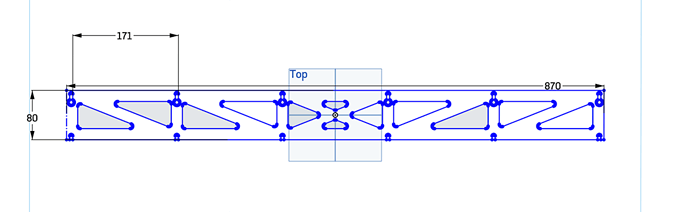

In this particular case it was a lot easier just to delete the miscreant line and redraw it co-incidentally than to try to adjust it. The process is very fast and took just a few minutes to have the drawing rendering correctly.

All that’s left to do is to convert that temporary construction line with a solid one, and to extrude the drawing.

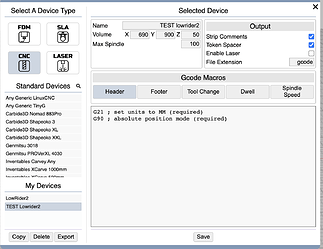

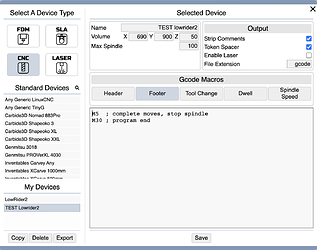

With that out of the way, I installed KiriMoto, which I think will be my free CAM package of choice, into Onshape, and quickly became overwhelmed with the setup, so the next instalment will have to wait for another day!