That is why I love this place and all who sail in her! ![]()

Best Crew Ever!

Well there’s another day I’m not going to get back. Spent a lot of it becoming familiar with Kiri:Moto’s most intimate parts, then becoming incredibly disgruntled with my complete inability to find how to fix my little “Z axis fails to lift on startup” issue. I was just about to toss it all in and sit in a corner sucking my thumb for a bit when @stewart bobbed up with a fix for what turned out to be a brand new bug or at least a problem I’ve discovered … or created.

There are plenty of other things that were my fault though, so I can’t get too smug.

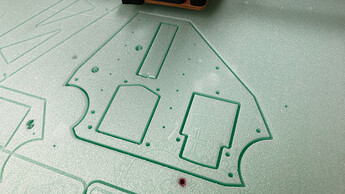

Thought I’d better print a K:M Crown too, direct from the .svg file, because I can, and it was a beautiful thing apart from finishing 6mm too soon, and while on the subject of being a bit short - the LR2 was supposed to be 800 x 1200 (1/3 sheet) but ended up not. Which means that it’s not big enough to do the first job I’m going ot throw at it; the LR3 struts. They’ll need to be cut one at a time and on the diagonal, but it looks as though they might work well enough now that I know they’ll (just) fit.

That’s sort of settled the new table size too. I made my lathe bench twenty years ago to fit in a particular space, and it doesn’t have to be as deep as it is. Therefore if I make a new top, and modify the lathe stand I might just squeak in a 690 x 1200 cut area which will be too small for the next job, but so be it.

Decision made.

Looks just about big enough to carve out that picture in 3D.

A long long time ago in a Galaxy far away, someone wrote:

I valued that comment so greatly that it stuck in my mind so firmly I could search it out now. You see, this IS my sportscar! I like to make things as nicely as I can and for me the changes and repairs along the way represent the geological history of projects I’ve made with the tool and the fun I’ve had along the way.

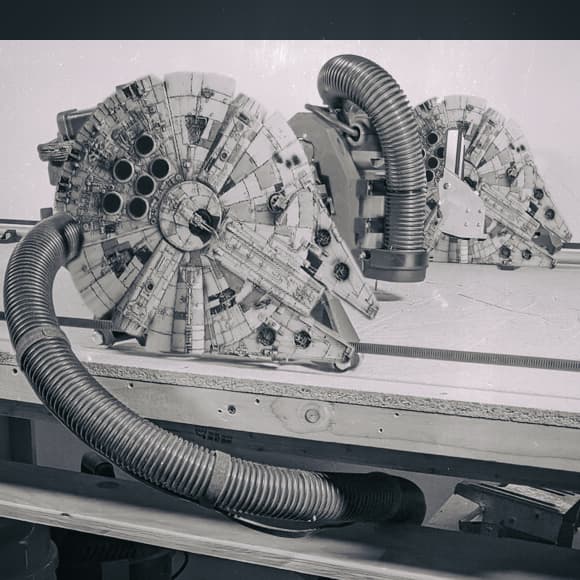

So I’ve been fretting about what colour to make it in, was going to make it two-toned like the factory model, then thought an all black “Darth Vader” might be great but now I think I’m heading towards melting some of my stock of Prusament Galaxy Silver.

Then I wondered why no-one has come up with some lovely side covers to hide all those whirring and spinning things.

Then the madness returned! ![]()

Do it!!

Well I like the whirring and spinning things… but I’d rock THAT in a New York Minute.

Hmmm… It’s been ten days since I fired up the LR3 and it seems like no progress, but I’ve spent a bit of time on the net. (The new cargo nets for the van)

… and on the other kind of net too. Life hasn’t been all fizzy pop and rope tying.

Ive got to know Vectornator and Boxy SVG Editor a little along the way and I think I’m driving @Stewart batty with my constant battering of questions, but I do like the way Kiri:Moto is bonding with me. ![]()

I’ve got most things I need for the LR3 practiced and locked in foam, so that’s good, and if I hit that “home” button one more time before I build the LR3 and put end stops on it, I will possibly scream.

Finally, a little deflated by the news that @vicious1 isn’t selling aluminium xz plates any more - I really don’t fancy steel ones but don’t know if I’m brave enough to cut my own.

On another note, may I ask how you deal with rust on your bearings? I give mine a going over with stainless steel wool, then rust converter then paste wax at least once per year, but I leave the machine covered in a locked house for four months and this is what they look like on my return - it’s why my tubing is stainless steel.

Cheers!

I am pretty sure you can find a business that is going to cut them for you in Australia. I paid 40 Euro in Germany for the two plates.

Yep, we have businesses that do that - I’m waiting on a quote from the only one that’s shown any interest so far… “waiting on a quote” sounds ominous though.

Mine were 12.50€ per plate plus 19% taxes and 11.50€ shipping. I found it pretty nice of them to cut me only two, can‘t have been very lucrative.

Some things are out of whack price wise here - and anything to do with metal is one of them!

I haven’t bothered to even look at xz plates before.

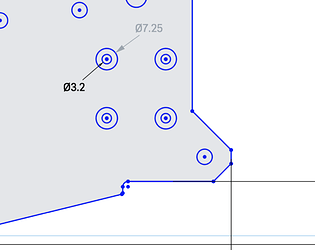

I’ll be getting a price in the morning - wish me luck, but I need to be reminded why two sized holes for the steppers? I know I’ve seen this question asked before but my eyes were glazed over at the time and I had a smug “well I’ll never need to know that” sort of smile. ![]() A quick search did not reveal a useful answer!

A quick search did not reveal a useful answer!

My choices are -

- Have them made correctly in the first place.

- Make them with holes too small and drill them out.

- Make them with holes too large and print some bushes to fix.

I’m happiest ![]() to run with 1) above if someone can enlighten me.

to run with 1) above if someone can enlighten me.

I actually had the conversation about the two holes with the manufacturer as well. The small ones are needed for the screws, the large ones are only needed for thicker plates as counter bore so the screws are long enough.

You can read about the exact values in the documentation.

Ahh yes of course - I remember now, I have read that many times!

Many Thanks.

I will revisit the aluminum they are just substantially more right now. I think it was nearly 50% more than steel per plate. And I was getting told I had too many options, kits were hard to make, so to simplify and take away one more option this seemed like a good choice, and lower the overall cost for the end user.

That rust is proving to be a bummer for some.

You know, the printed ones are fantastic. I am not convinced the metal plates add much.

I will re-visit that after I receive the quote this morning! It’s funny, I’m sure that if I read the documents, they’d say:

The only way to get any more rigidity is going to metal.

Which of course is like waving a red flag - of course I want more. No matter whether that rigidity already exceeds the parameters for anything I am ever likely to build. Logic and rational thought are not a factor when one’s brain just wants the biggest and the best for the sake of it.

I did have a mind to polish the aluminium ones, so printing them will mean that’s one more skill I won’t have to learn, although I will have to re-visit my colour scheme. ![]()

Don’t let my voice change your plans re:simplifying your product line, there are times when “less” is more! ![]() Have you considered using stainless steel @4mm or 3/16" ?

Have you considered using stainless steel @4mm or 3/16" ?

Cheers,

P

I can completely understand you. I build the MPCNC out of stainless steel and I am going to do the same for the LR3. Not needed, I know, but somehow I feel better knowing it can’t and won’t rust. ![]()

Well I have 20 or so sets here right now and they are starting to surface rust. Not cool. Shoot.

Dip them in vinegar and tell us that it’s a “thing”, or get the next lot out of coreten and it will be.