Awesome, thanks for sharing!

I changed the Front Belt file, in case you were going to use it.

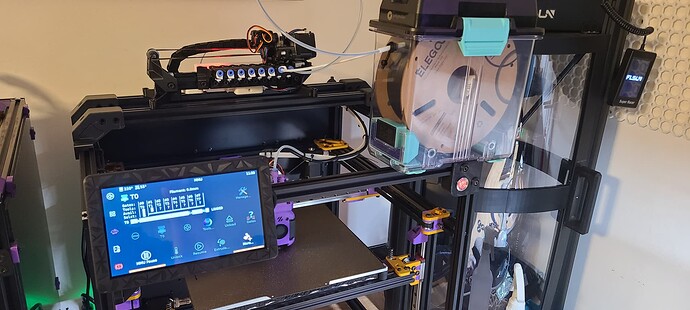

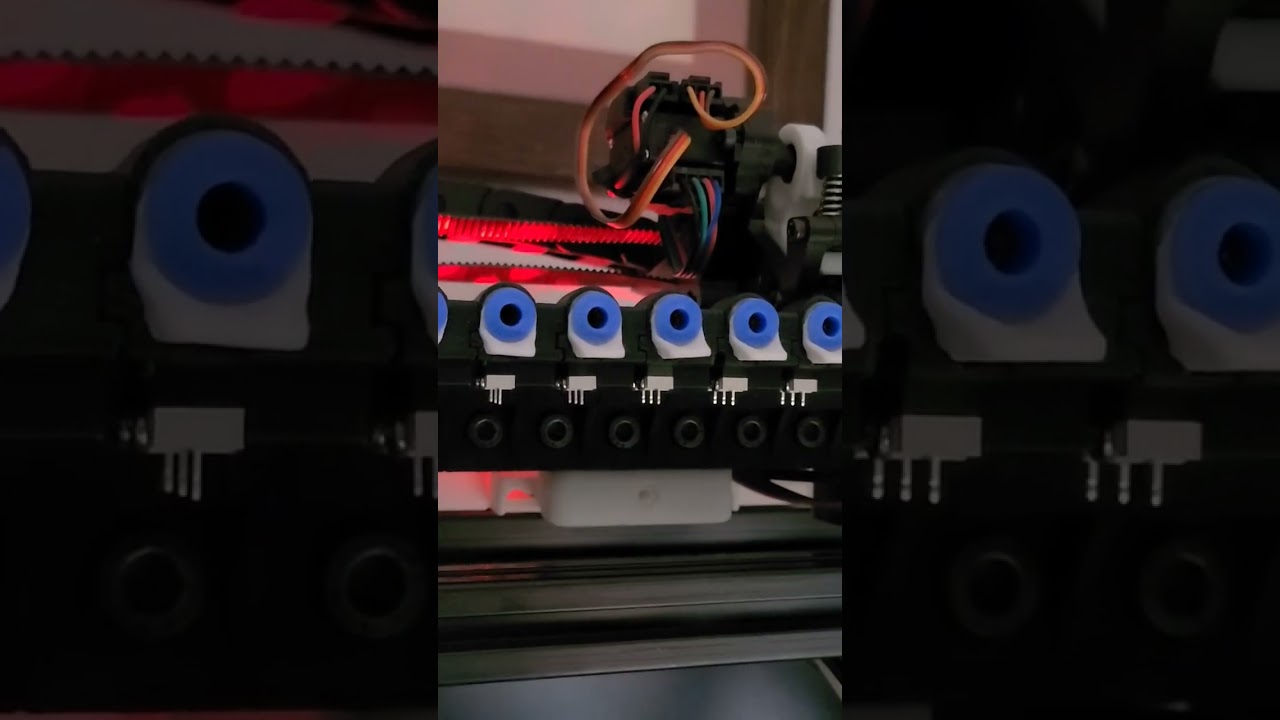

Tradrack working?

Yessir! Working a couple issues out. It pauses the print when it changes tools. Not sure why yet.

Will take some videobor it doing a change in the next couple days.

I paused messing with the chameleon because it tangled the roll when it tried to swap colors… rewind needed. I haven’t had time to figure one out that will work inside my drier box. Glad you got yours working

using polymaker dryer boxes and putting the rewind inside with the spool. works pretty well after you loosen up/use some of a new roll.

Filament cut, retract and change with purge.

I want to rig up a system to make it make “poops” and then brush the nozzle. Still working on that. Also i am having an issue with Happy Hare parking the toolhead and pausing after a tool change. I have to go in and press play again to finish the print.

That polymaker box has a rewinder in the lid?

It does not! It just works out that it will loosely spool just enough in there around the spool.

I am probably going to add a buffer into the system but am just trying to decide which one makes the most sense. I like this one:

ERCF_Mods/Carrot_Quiver_Buffer at main · SkiBikePrint/ERCF_Mods · GitHub

and this one has merit also.

MMU Filament Buffer ~900mm by WiggyWooSaa | Download free STL model | Printables.com

My plan is to set up 4 on each side of the printer and the boxes on a shelf behind it.

Do those “buffers” actually rewind or just provide a space for the pushed-back filament to sproing wherever?

those just provide space. I want to do filametrix rewinders but I really like the polymaker dry boxes. I wish someone would figure out how to incorporate an active rewinder into one of them.

Filamentalist?

I had researched a couple solutions for enclosing them in case I ever got around to it…

I was going to try to make something like this:

probably could redesign with some active drying as well…

Yep. That one.

Looking at your box, I’m wondering if I could put a rewinder in the lid of my drying box… Maybe just replace the lid. Hmmm…

I wonder if you could make an insert that would drive the roll like the filamentalist ones but mounted on the top. Maybe spring loaded? That would make it so it could be used on the dryer base still also.

I will tell you that as soon as the new spool got unwound a little i have had no issues with just letting it unspool some.

Was filling some down time today and came across a few filament rewinders that ae designed to use printed springs and a clutch. A few are made to have the roll ride on top but there were a number that went through the center of the spool.

Since the Drybox has a way to hand the spool from a center spool why cant we just use the spring idea and an offset axle…

My one way bearings just arrived…