So my CoreXY laser is dead. RIP.

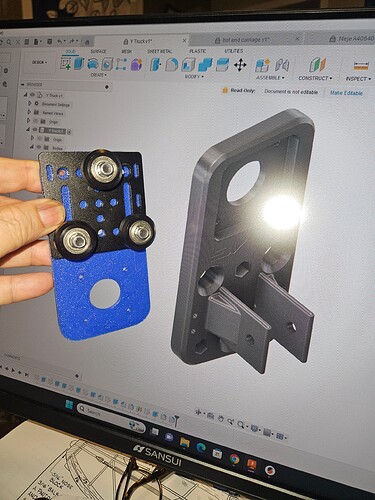

When I started on the MP3DPv4 I bought a bunch of 2020 V slot and 2040V slot, as well as many misc items that work with it. I was quite interested in the V slot and the various wheeled thingamabobs that use it. I expected the same mini wheels that the ZenXY and MP3DPv3 use, but these are bigger, so I didn’t get to use them as I expected. I bought several of the 3/4 wheel V slot gantry plates, and a couple of the Ender 3 style hotend sliders, as well as a few other styles, but (so far) those don’t seem relevant.

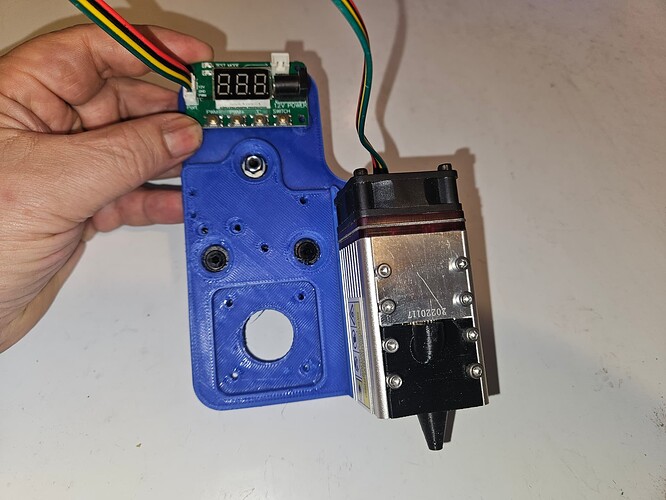

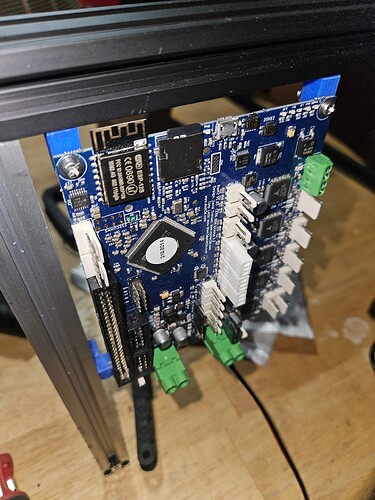

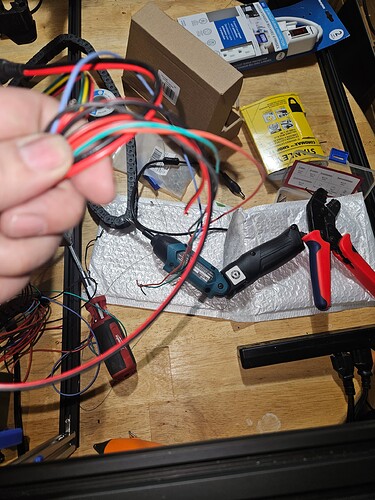

So I have 2 of these NEJE 40W (10W optical) laser modules, several NEMA17 motors and more control boards than I can shake a stick at. (And I’m a fair hand at stick-shaking, if I do say so myself. ![]() )

)

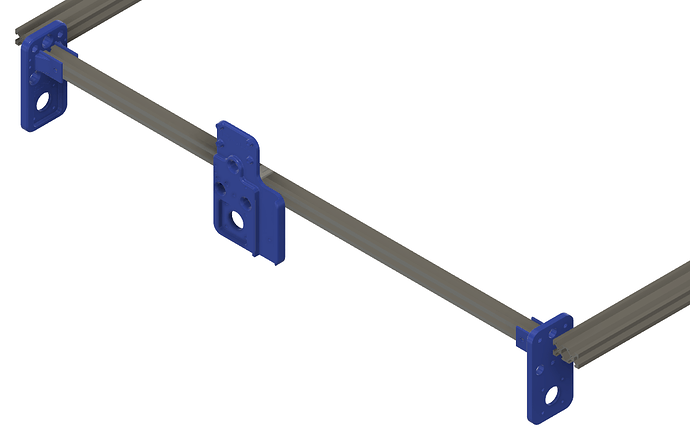

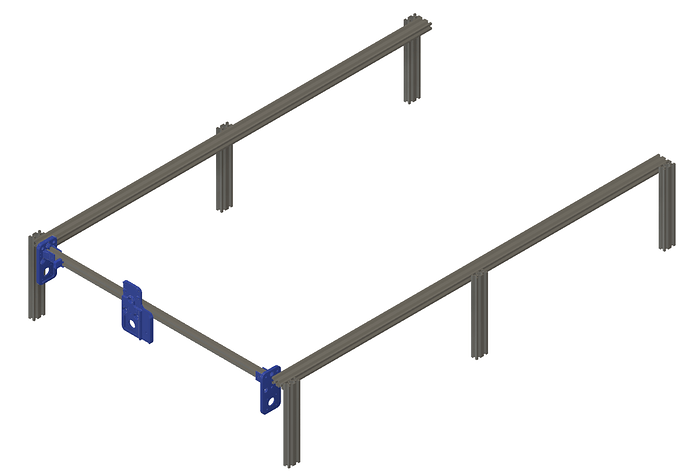

So the idea will be the basic extrusion frame box. A floor made from 1/32" steel sheet, because. I want it to manage 20" by 30" .aterial at a minimum, and if I can swing it, 24" by 48". I have 2m pieces of V slot, so I think it’s doable.

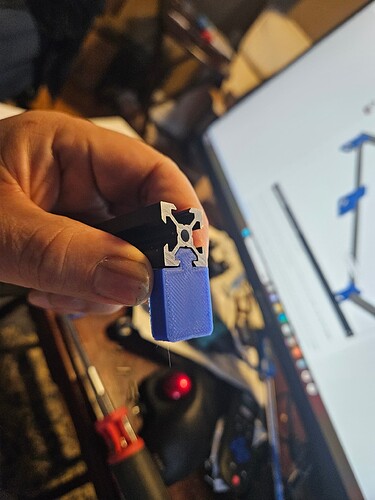

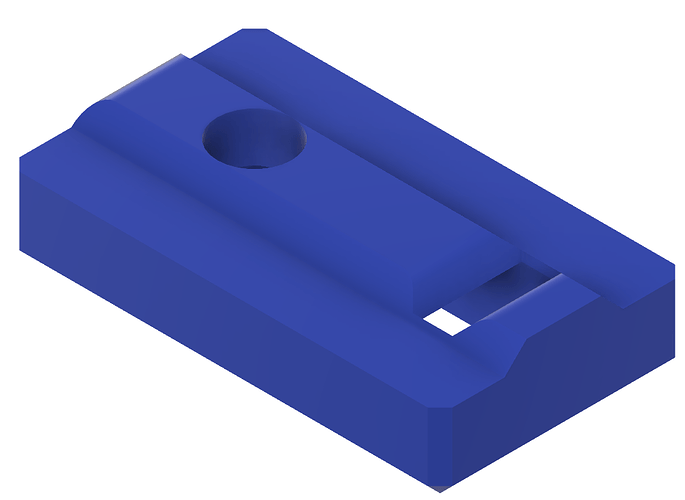

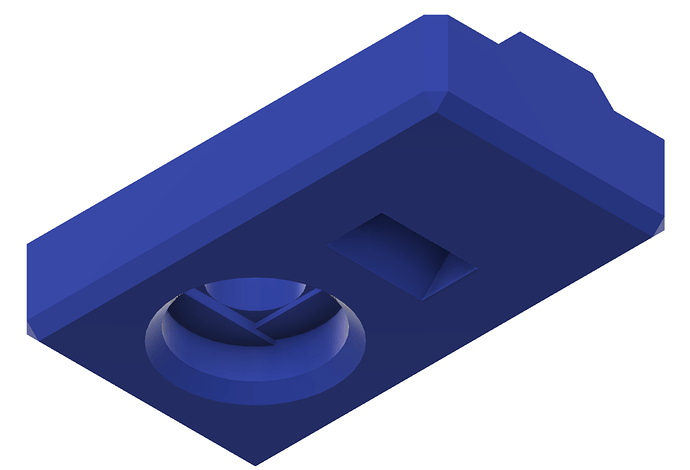

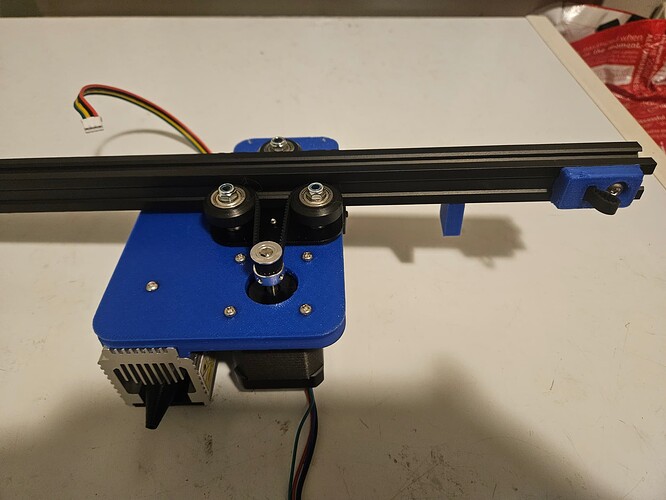

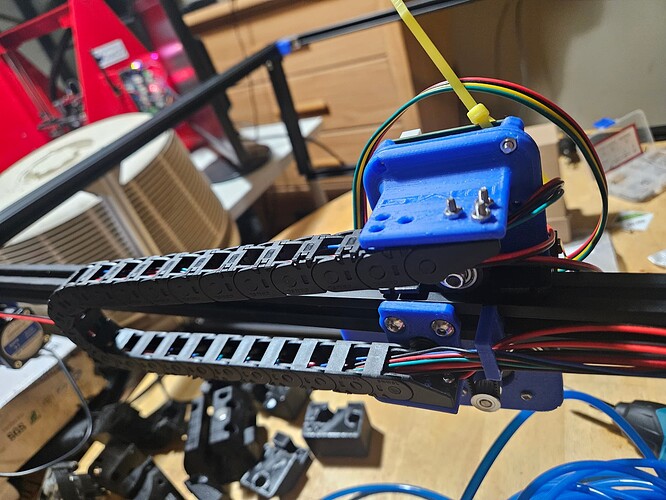

The wheel gantries sure do cut down on the complexity of the 3D printed pieces, and the cam offset wheel axles take care of adjustment nicely. I have a rough draft of trucks and a core thst should work.

The plan is to make 2040 rails for the long Y axis, and use dual Y motors, one on each truck. I also will make an allowance for dual endstops, because why not?

The rough draft has no provision for a Z axis on the gantry, but maybe I can rig something for the floor of the laser… it could even be entirely manual, I think.

I also want to be able to use a rotary axis, which is my one and only reason for not going CoreXY on this version.

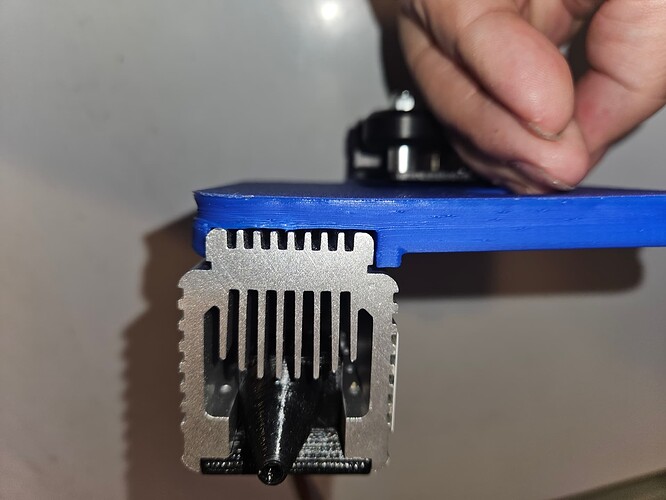

I had an idea for the belt drive. If the belt is in the V slot (only 6mm belts work for this) I can use the wheels as idlers to pull the belt around the drive pulley. I dismissed the idea, but I kind of liked it. Turns out that Openbuilds does the same thing for some of their gantry builds, and I’m using some of the same gantry pieces, so I ran with it.

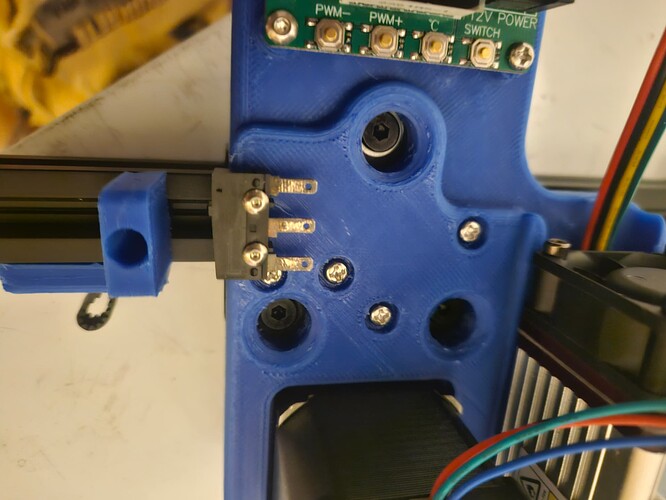

One thing that never seems to get addressed with the NEJE laser mounts is the control board, so I have a provision for that, too.

Well, going to fire up the printer and try these rough draft pieces.