I have done it 2mm, but than I realized that it is not so important, go with 1/8

That is the gap for the belt to slide down into the X min Z stub. Larger with the 1/8” will work or you can use a dremel. Either way will be ok.

Imo yes, maybe @vicious1 can confirm that

It’ll be fine.

If you have problems later, those are possibly the easiest to replace!

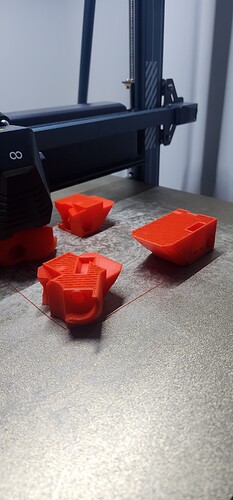

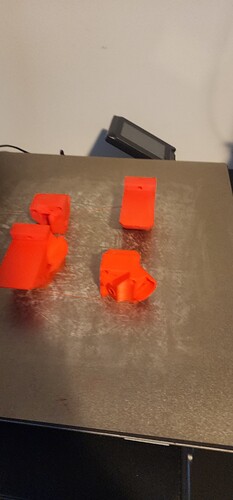

I’m surprised you didn’t print everything all at once on that Big Boi plate!

Hey ryan, you need an LR4 3d printer to print out a ton of parts all at once. one 4x8 print bed, voilla! Set it to print a row at a time so the lr4 can go up and down. A row of cores for you, and you and you ![]()

And for that you can connect a 10 kg roll ![]()

I do need to start getting some larger rolls again.

These days, I bet the mesh bed leveling is good enough to easily do a 4x8 bed now, but I don’t think my power grid could handle it.

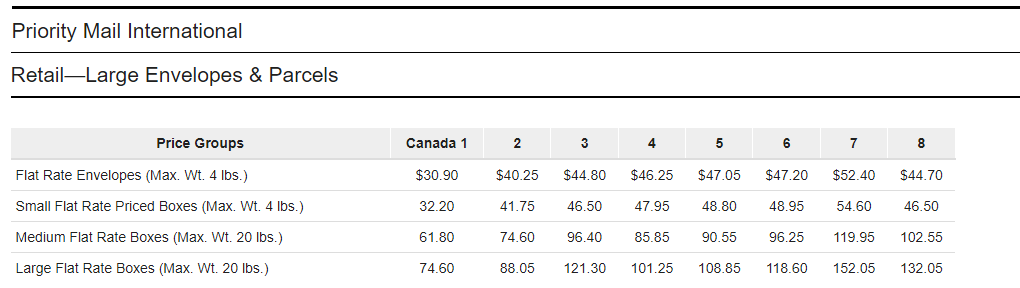

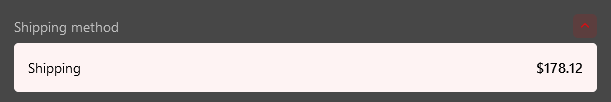

Core instructions are up and all the printed parts shipping is on order, finally. I had to sort every single country one at a time into 8 zones. I would love to do it for the rest of the products. Some international users would save a little on shopping and some would pay a lot more.

I currently sort of average the shipping costs by the common zones I ship to. check out this range

Zone 7 is - Russia, no shipping there so it is not part of the average anymore, I did ship a handful of orders there before the war.

Zone 8 is all the remote stuff, hard to get to.

Zone 2 is south america.

Most of the international shipping is Canada, then 3-6.

A little behind the scenes…

Having a physical product business that ships is so overcomplicated. The shipping industry is ripe for massive disruption. USPS posts a list of prices, it is long and convoluted and changes a couple times a year. No other carrier has a list like this. The only way to set a pricing schedule is to actually check a real address with dimensions and weight for every box. You can do carrier calculated rates, you have to pay a lot more for it, but shopify does not have dimensions, only weight. So that pretty much rules out international rates being valid unless you are shipping lite stuff. We hit volumetric rates pretty often.

The good news is any time I have ever checked another carrier the USPS rate is the least expensive. USPS has a flat rate option so volume is fixed, no need for per order calcs.

That’s only my side, when the box gets to the destination country the buyer has to deal with import tax ~50% of the time. I can charge and pay the import tax on my side but then I would need to file taxes in every single country I collect taxes on, sometimes multiple times per year.

There has to be a better way to trade goods internationally.

Is it all worth it, international sales make up 27% of my sales as of yesterday. So…kinda

Hi Ryan,

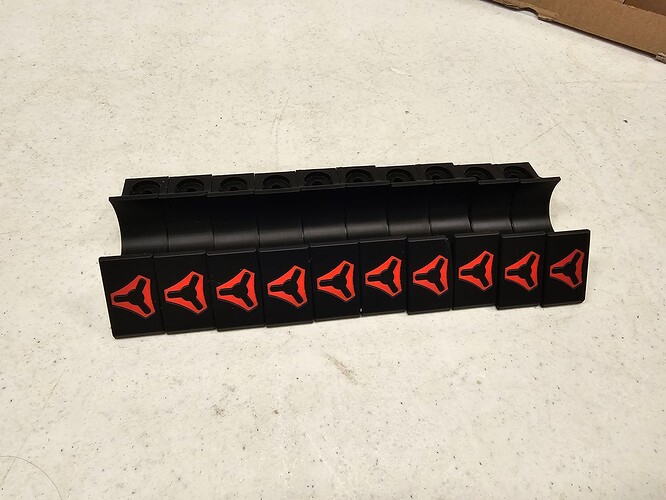

Does the number of braces affect the rigidity of the LowRider? How many should I use for an axis width of 1220 mm? I’ve printed 7 so far—do you think that will be enough?

The linked calculator handles all of this. If you want to do something different you need to make sure your board fits between the braces.

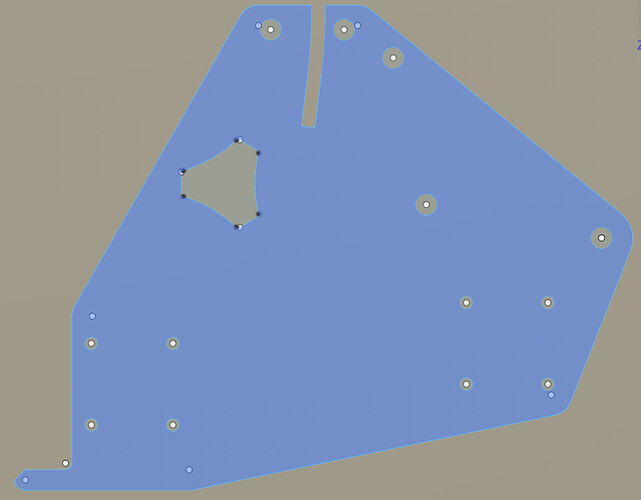

![]()

Yes, I did that as well.

1220 mm / 7 braces = 174.3 mm between center to center of the braces, and since I think the braces are 18mm thick, actually only 156.3 mm between each brace, so yes, 7 is plenty.

I used the LowRider to cut the wide part of the slot, and used band saw to cut the narrow part of the slot.

Hmm, if I look at your list and look at what shipping would cost me, something is not right:

It doesn’t even tell me which box. ![]()

I added a hardware kit and printed parts.

Your days of cheap shipping are gone!

What country?