I’ll have to look at some of them just out of curiosity!

I think you can increase the feeds and speeds without any issue.

My suggestions are:

-Stay around 18000rpm(test the value with spectrometer app on your phone, put some tape around the endmill, like a flag, to increase the noise. Hz*60=rpm)

-Use a single flute endmill, at a given rpm is slower than a 2 flutes, but have a better chip evacuation and can go deeper without issues. The LR works better with high DOC and “low” feeds.

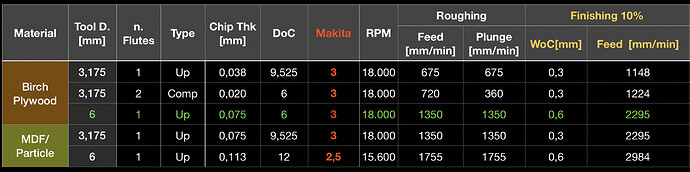

-Start with this chip load values (for 1/8” and 1/4” single flute bit)

MDF 0,15mm

Plywood 0,075mm

-start with DOC half of endmill Diameter.

(If You go higher than 1xDiameter reduce the chipload to 75%, if You go higher than 2xDiameter reduce it to 50%.)

-finishing pass 10% of endmill Diameter. And increase the finishing feed by 1,7x due to chip thinning(this value works only with 10% pass).

-for single flute endmill your plunge rate can be equal to feed rate(it’s scary, but works😅). NB: Anyway the stock firmware is limited to 900mm/s on Z

That said you can start from this:

1/8 single flute, 18000rpm, 1350mm/min, DOC 1,5mm, (finishing pass 0,3mm 2295mm/min)

1/4 single flute, 18000rpm, 1350mm/min, DOC 3mm, (Finishing pass 0,6mm 2295mm/min)

If your machine can’t handle this values, probably it’s due to poor built quality.

These are my parameters(some of them were impossible to reach with my first build, same components, but low quality assembly):

It’s only for show you that the LR3 can be a good machine.

All of that is good info, The only change I would make is use a much lower RPM. I use a 1-2 on the speed dial of all my routers. I don’t think I ever go over 3-4. The endmills we use are rated for much lower RPM, that is why single flute work better than two flute (half the RPM). Never use a 3 flute or higher, ever.

Most of the endmills’ datasheet say 18k rpm, and Makita say that long jobs at low rpm can be bad for the router. I started from these two things, but I can be wrong.

The chipload is a more important number I believe. The charts do things in a standard way, like at 1D depth, but 18k is only half the equation, so we need chip load or feedrate to calculate chipload.

Changes dial from 6 before anyone notices

Good thing the 8 flute endmills that came in my kit seemed like a joke to me in the first place

![]()

![]()

I would assume this makes then run a lot cooler

I legit had the same thought! Good news is the router is MUCH quieter at that RPM

Yea, all my calculations start from Chipload,

after that I look for DOC, to maximize Cutting Force.

Reducing rpm, with same chipload, doesn’t reduce the cutting force, so it didn’t seems to be an improvement, only a slower feed ad a smaller MRR… my chip is warm, and the endmill is cold(you can touch it with bare fingers).

Please let me know if I’m missing something, I’m always looking for improvements in my workflow!![]()

Nope. rpm x feedrate=chipload. So what you did there was increase the federate without noticing it.

F&S is not a nice set of linear EQs. It’s more like a hypercube envelope where you have 5 or 6 knobs to turn (bit size, # flutes, material hardness, etc.), but then you end up looking at the shadow of the result on two separate planes to get your dynamic inputs (feeds and speeds). It makes my eyes itch, and I feel like I’m on a bad episode of Maury or something, as it feels like it’s just an unending stream of “but what about…” and “did you take into account…” and “oh, and you have to figure in…” and “OMG, she’s your sister!”

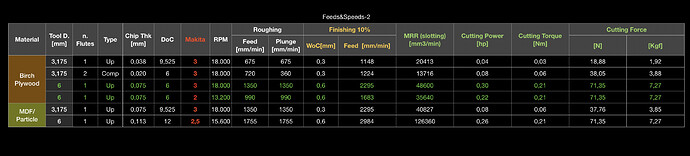

These are my F&S parameter, as You can see I highlighted in green two rows, same tool, same chipload, different rpm. The difference is only about MRR and Cutting Power. The Cutting Force is the same.

My conclusion is that my LR3 can handle about 8Kgf without skipping steps or chatter.

So, after found the best Chipload, I try to adjust other parameters to reach the maximum Cutting Force the machine can handle, and after that I aim to increase the Cutting Power to make the most of router power.

I figured out that reducing too much the rpm cause a longer machining time without other noticeable benefit.

RPM must be as high as possible, until the feed value becomes limiting for the stepper torque.

17 pounds for use odd units users.

That is really really good.

That seems backwards. We are never short on RPM or spindle power, heck even speed. Rigidity (your cutting torque) is our only concern. Monitor your part dimensions to assure that you are keeping the precision you need. I can cut way faster but at some point accuracy goes out the window (in wood and plastic).

Glad you are having fun with it and mapping things out. Remember your tool does wear so never ride thing to the limit, leave overhead for a dull tool that adds significant load.

You want to cut as deep as possible per pass to prolong tool life and still get chip evacuation. Divide your depth of cut evenly for your project (no sense in doing 4mm 4mm and .5mm on a through cut).

If you look at my speed tests on Youtube the measurement was a go/no on accuracy in XY and Z.

Chipload is important because you need to get a large enough bite of material not to be rubbing, or small enough not to break the bit. That is why it is the first step in calculating a tool recipe. So if you start with the smallest chipload recommended for that end mill and that material from there you can get a feedrate and RPM combo you like. Then you can adjust the depth of cut to add load if your machine can handle it, or reduce it if it can’t. (Always double check whatever chart you are getting chipload from, they do not all use 1D, some even list .5D-3D)

If that all works out and cuts well you can start increasing the chipload (higher feedrate or lower RPM) to make more efficient use of your machine.

There will always be a range of acceptable values. Depth of cut is usually set by your material thickness and the material’s ability to clear chips. So rpm and feedrate are the main two adjustments.

2 posts were split to a new topic: How to set up test cuts?

A post was split to a new topic: Chipload questions

Sorry to jump in late. I’ve just built my LR3 a few months ago and I’m getting into learning about all the parameters. I think that maybe what Enrico was saying is that assuming you are cutting with a certain fixed DoC (because the material is set at that depth or w/e), if your motors allow for a higher load, you should increase the feed rate to cut production time. To maintain chipload, you should also increase RPM. Of course, in different materials you could just opt for lower RPM, lower feedrate and higher DoC