I’m a glutton for punishment.

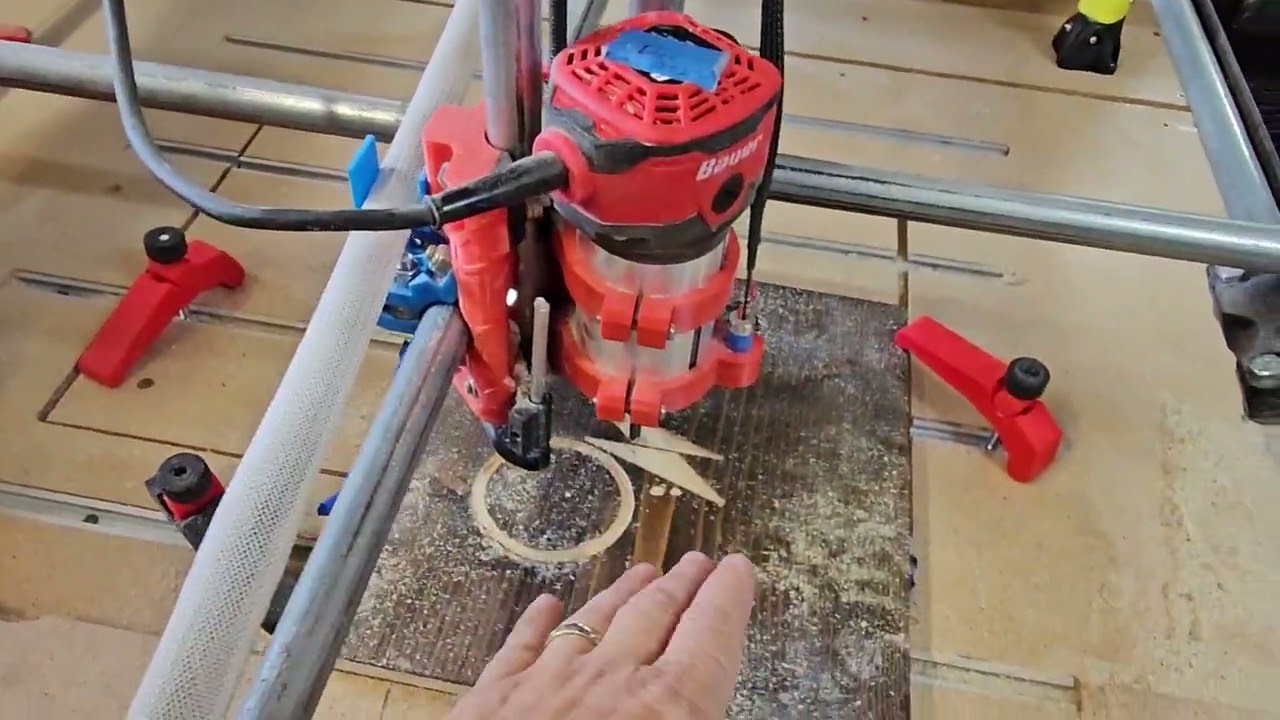

Even though I say I’ve had enough trying to figure how to make this thing do something I want it to do, I come back to try again.

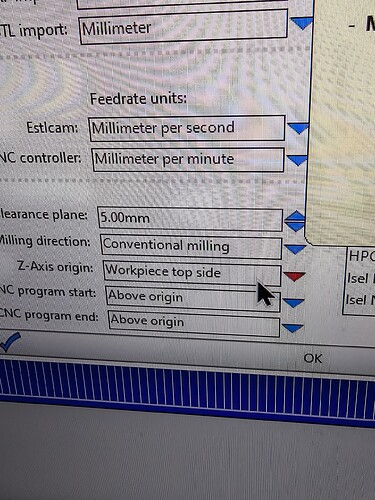

I may have figured out how to do a simple bit of text (maybe) but I can’t get it to zero out at the top opf the workpiece.

I start the program and the Z axis raises and it cuts air.

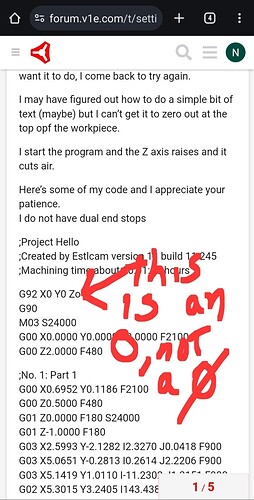

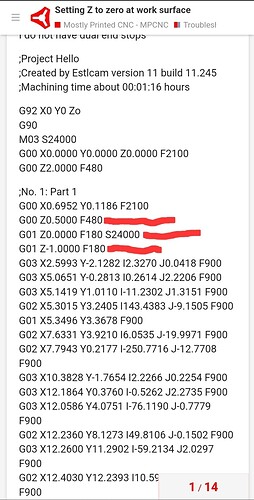

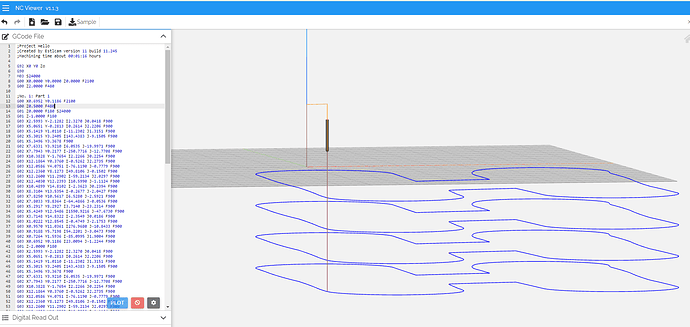

Here’s some of my code and I appreciate your patience.

I do not have dual end stops

;Project Hello

;Created by Estlcam version 11 build 11.245

;Machining time about 00:01:16 hours

G92 X0 Y0 Zo

G90

M03 S24000

G00 X0.0000 Y0.0000 Z0.0000 F2100

G00 Z2.0000 F480

;No. 1: Part 1

G00 X0.6952 Y0.1186 F2100

G00 Z0.5000 F480

G01 Z0.0000 F180 S24000

G01 Z-1.0000 F180

G03 X2.5993 Y-2.1282 I2.3270 J0.0418 F900

G03 X5.0651 Y-0.2813 I0.2614 J2.2206 F900

G03 X5.1419 Y1.0110 I-11.2302 J1.3151 F900

G02 X5.3015 Y3.2405 I143.4383 J-9.1505 F900

G01 X5.3496 Y3.3678 F900

G02 X7.6331 Y3.9210 I6.0535 J-19.9971 F900

G02 X7.7943 Y0.2177 I-250.7716 J-12.7708 F900

G03 X10.3828 Y-1.7654 I2.2266 J0.2254 F900

G03 X12.1864 Y0.3760 I-0.5262 J2.2735 F900

G03 X12.0586 Y4.0751 I-76.1190 J-0.7779 F900

G02 X12.2360 Y8.1273 I49.8106 J-0.1502 F900

G03 X12.2600 Y11.2902 I-59.2134 J2.0297 F900

G02 X12.4030 Y12.2393 I10.5990 J-1.1124 F900

G03 X10.4899 Y14.8102 I-2.3623 J0.2394 F900

G03 X8.3104 Y13.5354 I-0.2677 J-2.0427 F900

G03 X7.8250 Y10.5617 I6.5280 J-2.5921 F900

G02 X7.8033 Y8.8364 I-64.4866 J-0.0536 F900

G03 X5.2917 Y8.2927 I3.7140 J-23.2314 F900

G02 X5.4249 Y12.5486 I1590.9216 J-47.6730 F900

G03 X3.7148 Y14.8322 I-2.3549 J0.0186 F900

G03 X1.0222 Y12.8545 I-0.4749 J-2.1753 F900

G03 X0.9570 Y11.0361 I276.9680 J-10.8433 F900

G03 X0.9188 Y5.7198 I54.2201 J-3.0473 F900

G02 X0.7264 Y1.5936 I-85.0995 J1.9004 F900

G03 X0.6952 Y0.1186 I23.0094 J-1.2244 F900

G01 Z-2.0000 F180

G03 X2.5993 Y-2.1282 I2.3270 J0.0418 F900

G03 X5.0651 Y-0.2813 I0.2614 J2.2206 F900

G03 X5.1419 Y1.0110 I-11.2302 J1.3151 F900

G02 X5.3015 Y3.2405 I143.4383 J-9.1505 F900

G01 X5.3496 Y3.3678 F900

G02 X7.6331 Y3.9210 I6.0535 J-19.9971 F900

G02 X7.7943 Y0.2177 I-250.7716 J-12.7708 F900

G03 X10.3828 Y-1.7654 I2.2266 J0.2254 F900

G03 X12.1864 Y0.3760 I-0.5262 J2.2735 F900

G03 X12.0586 Y4.0751 I-76.1190 J-0.7779 F900

G02 X12.2360 Y8.1273 I49.8106 J-0.1502 F900

G03 X12.2600 Y11.2902 I-59.2134 J2.0297 F900

G02 X12.4030 Y12.2393 I10.5990 J-1.1124 F900

G03 X10.4899 Y14.8102 I-2.3623 J0.2394 F900

G03 X8.3104 Y13.5354 I-0.2677 J-2.0427 F900

G03 X7.8250 Y10.5617 I6.5280 J-2.5921 F900

G02 X7.8033 Y8.8364 I-64.4866 J-0.0536 F900

G03 X5.2917 Y8.2927 I3.7140 J-23.2314 F900

G02 X5.4249 Y12.5486 I1590.9216 J-47.6730 F900

G03 X3.7148 Y14.8322 I-2.3549 J0.0186 F900

G03 X1.0222 Y12.8545 I-0.4749 J-2.1753 F900

G03 X0.9570 Y11.0361 I276.9680 J-10.8433 F900

G03 X0.9188 Y5.7198 I54.2201 J-3.0473 F900

G02 X0.7264 Y1.5936 I-85.0995 J1.9004 F900

G03 X0.6952 Y0.1186 I23.0094 J-1.2244 F900

G01 Z-3.0000 F180

G03 X2.5993 Y-2.1282 I2.3270 J0.0418 F900

G03 X5.0651 Y-0.2813 I0.2614 J2.2206 F900

G03 X5.1419 Y1.0110 I-11.2302 J1.3151 F900

G02 X5.3015 Y3.2405 I143.4383 J-9.1505 F900

G01 X5.3496 Y3.3678 F900

G02 X7.6331 Y3.9210 I6.0535 J-19.9971 F900

G02 X7.7943 Y0.2177 I-250.7716 J-12.7708 F900

G03 X10.3828 Y-1.7654 I2.2266 J0.2254 F900

G03 X12.1864 Y0.3760 I-0.5262 J2.2735 F900

G03 X12.0586 Y4.0751 I-76.1190 J-0.7779 F900

G02 X12.2360 Y8.1273 I49.8106 J-0.1502 F900

G03 X12.2600 Y11.2902 I-59.2134 J2.0297 F900

G02 X12.4030 Y12.2393 I10.5990 J-1.1124 F900

G03 X10.4899 Y14.8102 I-2.3623 J0.2394 F900

G03 X8.3104 Y13.5354 I-0.2677 J-2.0427 F900

G03 X7.8250 Y10.5617 I6.5280 J-2.5921 F900

G02 X7.8033 Y8.8364 I-64.4866 J-0.0536 F900

G03 X5.2917 Y8.2927 I3.7140 J-23.2314 F900

G02 X5.4249 Y12.5486 I1590.9216 J-47.6730 F900

G03 X3.7148 Y14.8322 I-2.3549 J0.0186 F900

G03 X1.0222 Y12.8545 I-0.4749 J-2.1753 F900

G03 X0.9570 Y11.0361 I276.9680 J-10.8433 F900

G03 X0.9188 Y5.7198 I54.2201 J-3.0473 F900

G02 X0.7264 Y1.5936 I-85.0995 J1.9004 F900

G03 X0.6952 Y0.1186 I23.0094 J-1.2244 F900

G01 Z-4.0000 F180

G03 X2.5993 Y-2.1282 I2.3270 J0.0418 F900

G03 X5.0651 Y-0.2813 I0.2614 J2.2206 F900

G03 X5.1419 Y1.0110 I-11.2302 J1.3151 F900

G02 X5.3015 Y3.2405 I143.4383 J-9.1505 F900

G01 X5.3496 Y3.3678 F900

G02 X7.6331 Y3.9210 I6.0535 J-19.9971 F900

G02 X7.7943 Y0.2177 I-250.7716 J-12.7708 F900

G03 X10.3828 Y-1.7654 I2.2266 J0.2254 F900

G03 X12.1864 Y0.3760 I-0.5262 J2.2735 F900

G03 X12.0586 Y4.0751 I-76.1190 J-0.7779 F900

G02 X12.2360 Y8.1273 I49.8106 J-0.1502 F900

G03 X12.2600 Y11.2902 I-59.2134 J2.0297 F900

G02 X12.4030 Y12.2393 I10.5990 J-1.1124 F900

G03 X10.4899 Y14.8102 I-2.3623 J0.2394 F900

G03 X8.3104 Y13.5354 I-0.2677 J-2.0427 F900

G03 X7.8250 Y10.5617 I6.5280 J-2.5921 F900

G02 X7.8033 Y8.8364 I-64.4866 J-0.0536 F900

G03 X5.2917 Y8.2927 I3.7140 J-23.2314 F900

G02 X5.4249 Y12.5486 I1590.9216 J-47.6730 F900

G03 X3.7148 Y14.8322 I-2.3549 J0.0186 F900

G03 X1.0222 Y12.8545 I-0.4749 J-2.1753 F900

G03 X0.9570 Y11.0361 I276.9680 J-10.8433 F900

G03 X0.9188 Y5.7198 I54.2201 J-3.0473 F900

G02 X0.7264 Y1.5936 I-85.0995 J1.9004 F900

G03 X0.6952 Y0.1186 I23.0094 J-1.2244 F900

G00 Z2.0000 F480