Did it get progressively higher as it cuts?

Yes.

I stopped it before it finished when I saw what was going on.

I think I’m snake bit.

This shouldn’t be as hard as I have it.

Lots of pictures & video.

What board are you using for control. Are you using pre- made wires or are you doing your own connections?

I am using a Rambo 1.3 (I think) and all wires are stock from V1.

Tomorrow, I’ll see if I can make a video but that may be a new set of technological challenges.

Thanks for sticking with me.

Looking at it now, the rambo looks like its a 3d printer base but adapted for cnc with 1 driver for x and y, but 2 for z. Ask i looking at the right one?

When you manually control the machine, and I’m not sure how you are doing this, such as by connecting a computer or perhaps you have a touchscreen, but when you manually “jog” or move the Z, does the “-” (minus) button move it down, and the “+” (plus) move it up?

Your G-code at the top of the thread calls for 4 downward cutting steps in increments of 1mm each, which should start cutting at -1mm, then cut at -2mm, etc, until finishing the cut job at -4mm deep.

Doug, The Z (now) moves up on ( +) and down on (-).

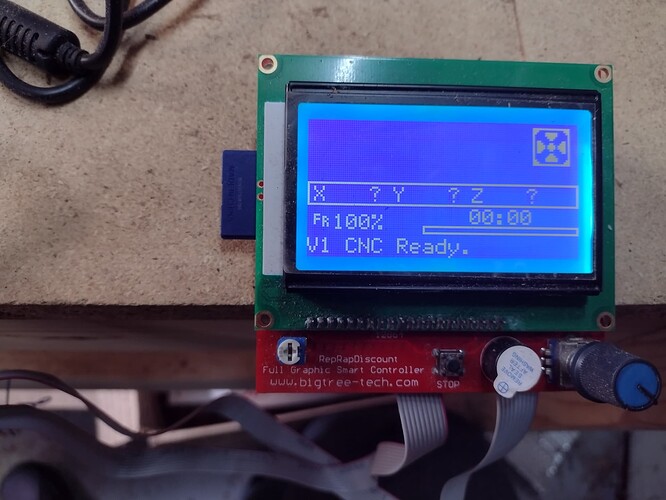

I control the machine from this board with an SD card.

For some reason overnight (through no effort of my own) I ran the program this morning and it carved something.

It doesn’t look a lot like what I attempted but it moved in the right direction.

Here is my version of “Hello!”

I think my mpcnc has artificial intelligence because I’m not sure how much the operator has.

Not knowing how long you let the machine run after you switched the z, it’s unlikely that your first plunge is directly at your origin. The bit will raise and then move in the air to its first plunge. It may look like it’s cutting in the air but it’s just moving and getting into position to cut.

Now that your wiring is straightened out, it doesn’t have much choice other than follow the directions it’s given and it comes down to learning the machine, bits, design etc to get the result you want.

Thanks for your patience.

I’d like to learn how to fish instead of being given a fish.

Do I need to learn Estlcam and Inkscape?

Where might one go to get this knowledge?

And the bits?

Is the free Esltcam limited compared to paid?

It seems I can’t seem to find a lot of the functions I see and hear about?

I have no problem in paying for it but wanted to see if I could do anything before I did.

I don’t believe so, no.

Unless you buy a licence you get a pop up on starting that you have to wait before you can dismiss and continue.

What functions are you having difficulty finding?

For example, picking tool paths.

There are others but can’t recall in my senility.

I’ve watched a lot of Youtube videos and they do stuff I can’t see how to do in my version 11

I learned everything I needed to know about Estlcam from the milling basics page. Well, and just picking stuff up reading the tooltips and such.

There is an intermediate page too. Ryan goes over how to do the 2.5D milling for his 12864 controller case (I made one in poplar, and one in oak) sides. This might be less useful now thst the TFT35 has taken over, I was looking at a milled edge for it, too.

Thanks for that info, Dan.

I swear I’ve gone over that often but will go again.

IIRC, I think that is an older version.

It’s the same, it just gets progressively more annoying. After a set number of cnc saves it adds 1 second of pause before saving asking with a pop up saying essentially “send me $60”.

I’ve used it with some basic work but it gets imo fairly unfriendly with more complex stuff like real vcarves. I put up with annoying saves, then switch to vcarve pro for other stuff. I’m sure the estl vcarve can be made to work i just haven’t felt the need to learn since i have the vcarve access and it’s just simple to do with that software.

I don’t mean it pauses 1 second, it adds another second for every save, i think I’m up to a minute+ : laugh:

Estlcsm has no design ability, so you do need a separate graphic program to do your design.

I have done a couple vids on the basics, just havent uploaded them yet. I’ll link them shortly.

Thanks again for your patience

Here’s basic toolpaths on estlcam. The screen capture didn’t get the pop ups for some reason but you’ve likely seen a file menu before.

The maker of ESTLcam has quite a few videos on YouTube showing how to use the program. Those helped me a lot. The process is, once you get it, very straightforward.

The free trial version has no limitations.

I paid for the ESTLcam program and I’m glad I did, and I use it often.

Any vector illustration program should be able to export to SVG or DXF, which can be imported into ESTLcam. Inkscape is free and open source. I have decades of experience on CorelDRAW so I am using a paid product instead of a free one.

The ESTLcam workflow is (and this may be an over simplification and I may miss something):

- Import an SVG or DXF file.

- Create or choose a tool entry in the tool crib, that has attributes matching your real world bit.

- Choose which kind of cut you desire to create, such a Part (for perimeter cut, aka profile cut) or Hole (for interior cut, with or without pocketing, etc), or Engrave (for following a line with some type of carving bit), or Drill (for straight down drilling type bits), etc.

- Tap on the line / vector art that the above selected cut operation should apply to.

- In the pop-up that appears, tell the cut operation how deep it should go, whether there should be a finishing pass, whether there should be holding tabs, whether there should be pocketing, etc.

- Repeat the above as needed.

- Save the project file.

- Save the CNC cut file (GCode file).

- Preview the CNC cut job on screen.

- Edit as needed if anything does not look right during preview.

Note that during preview, both before launch of animation and during it, you can rotate in 3D space to make sure of what’s going to happen.

You should also just download 12, I have been using it exclusively since it’s out.

Also, I feel that Nathan complaining that a program has a popup that it free besides that is kind of unfair. Compared to the 700 Euros I would have to pay for V carve pro 50€ is a damn good bargain (plus, even v carve can’t do inlays well, carves have never been a problem with Estlcam, so that might be a user problem…).

One person develops it and puts a lot of time and effort into it, and you would not work for free either. See it like that: You wouldn’t even work for free if someone had to listen to a 60-seconds sales pitch of your services every time you did something.

Sorry that this sounds harsh, but I think it’s rather unfair to complain about the popup. ![]()