Hi i have got my masjien working nice but when i want to do an task i set the bit 1mm about the place to cut and when i press start it dont want to go down it mstay the same hight. It shows on aspire 9.5 that there are plunge line but nothing happens the z just stay in the same place. What can i do or what am i doing wrong please.

In order to troubleshoot this problem, it would be helpful to see your g-code file. Try to upload the file that is failing to a post. See this icon above:

![]()

If that fails (usually because the file is too big), you can open the g-code file using any text editor and past the top 25 lines into a post.

I assume you can move your router up and down electronically outside of a g-code file?

Hi Robetbu the masjien is moving everting nice and i let it run with the crown model an it did the hole sycle.

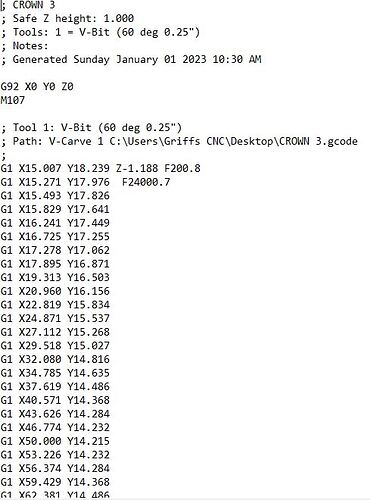

Your plunge g-code looks fine. It is only descending -1.2mm which can be pretty hard to see. To set up a router job like this, before you run your job, the tip of the bit should be just touching the top of the stock. You indicate that you set up your job with the tip of the bit 1mm above the stock. If that is the case, your -1.2mm may not be noticed. If you are trying to set up another pen job, and you are setting the bit 1mm above your paper, your 1.2mm plunge is not enough to place the pen on the paper with some pressure.

But there is another potential problem with your g-code. On the second G1 line, you have set the federate 24,000. If you are using V1 maintained Marlin firmware, it will limit the federate to 3,000, avoiding major complications, but 24,000 is way too fast for any routing and is likely a mistake in your CAM.

Do you maby have an image how can is set the bit for diffrent dept please. I wil have an look at the feed rates thanks.

I am not sure the exact question you are asking. If you are asking about how to set the depth of cut in Aspire, I don’t know. I use Fusion 360. There are very few Aspire users on this forum. Most use EstlCAM. You might get an answer by asking this specific question as a new topic.

There is an added issue. The g-code you posted says “v-carve.” If this is a true v-carve toolpath, the depth is set by the width of the pocket being carved. The CAM will work to keep the edges of the bit on the profile lines. The primary way to go deeper is to increase the size of the profile being carved. I’m not sure this is really a v-carve toolpath since there is no Z height variation in the g-code. Usually with a v-carve toolpaths, the z height will vary a lot as the CAM works to keep the edges of the bit on the profile. It might not vary if the profile is composed of parallel lines and a square endcap.

As for setting the bit to the top of the stock, it can be done manually. Place a piece of paper on the top of the stock and move the router bit down until the bit drags on the paper. You should still be able to move the paper.

Thank you very much Robert. i still have an long way to go and learn driffrent programs and settings, i only know what youtube showed me and fusion looked scary for me but i have to learn it also. All the best for the new year to all.

Well there ends my day in sadness fifirst nice cut on the crown almost done hade 90% done and this happens. I would gess all the boards are burnt out.

That happened to me too. It’s a real fire hazzard and one common issue on the RAMPS 1.4 board. I switched to screw terminals to prevent that. Some users solder the wires directly to the board to avoid situations like that.

Ouch. Fortunately, Ramps boards are not too expensive, plus the Mega 2560 may be okay. Do you know why it melted? It looks like you had a short at the connector. If you are not real careful with screw terminals, stray wire strands can short out at the connection. It cost be a bit of money for a kit, but I now use ferrules for all screw connections.

I doubt the RAMPS and Mega suffered any damage.

Test by connecting the USB cable to the board and check communications with pronterface.

If all is OK replace the melted connector and give it a go.

I have replace the plug an first check with the usb with no power from the board and it still work but when i connect the power nothing is happening. I gess i must get an new board

I looks like the plug made an hot connection where the plug connects to the board on the one pin no idee why that happens. But i wil replace the board.

Agree on the use ferrels. They are not expensive and do save some of these type issue though maybe not yours! luckily it just meted and no major flames looks like!

Yes i will do the ferels gonne order new board today.

If you connect the board with the power supply (no usb cable) does the board light up?

If not the voltage regulator on the Mega might be dead. If you are handy with a soldering iron you can replace it as this only cost a few cents.

Also you can check if the polyfuses (those yellow components behind the connector) are dead or not. Either use a multimeter to see if they are working or temporarily shortcircuit them with a wire (just for test purposes). Those can be replaced too. You can replace them by some auto fuse support and use auto fuses that are easier to replace.

Oky just an update i have soldier the wires direct to the board and romved the plug started evry board up alone an both working i put everything togeter and verything worked…but just an few small moves with the masjien its like the power is gone but the lights on the board is on and all i hear then is an CLICK CLICK CLICK CLICK sound and then swith verything off restart all again but then the same happens. Do you think i must get new board (the ramps and mega board) or redo the software.

Can you upload a video showing the issue?

That would help alot.

Reuploading the firmware and reseting eeprom won’t do any harm for sure. You can and should do that.

If you have a multimeter check if the voltage drops too much while moving. Although not probable the PSU might have take a hit.

Do you still have the polyfuses on the circuit?

Are you using Usb to power the Mega or the psu only?

Do a visual inspection on the ramps and mega to see if any of the traces have any damage.

Oky iets was the powersupply that was wrong gone new one and all is working but 1 thing the stepper are getting very very hot is that normal

They are getting warm, but not as warm as to smelt the PLA.