Looks like my endplate prints are staying flat now. This is the 1st print which started to pull up on the V-slot corners & 2nd print stayed really flat. I printed this endplate with 4 perimters & only 30% gyroid. I think once the V-slot & motor is connected it will be quite solid.

Since I am printing the wheel with tighter tolerance (22.3mm for 22mm bearings), I wanted to be able to get those bearings out if I wanted to. I think these 5mm access holes should work & not cause any problems in the design.

or suspend the wheel by the bearing in a 350F oven…  Only thing left would be the bearing and a pile of PLA goo.

Only thing left would be the bearing and a pile of PLA goo.

I don’t think my wife would appreciate me doing that & also those bearings have some sort of plastic or rubber seal around them that would probably also melt.

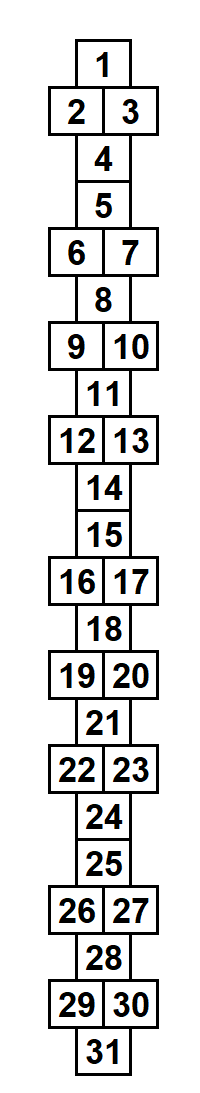

In order to know better what height spacer to use between the wheel bearings I added slots that my caliper would fit in. Even though the design is 10.75mm between them, it comes out to 10.5mm so this was a useful test print. That was a lot better than trial & error printing to determine what the height should be. Here is an image with the spacer in place.

My 1st new wheel print failed for some reason half hour into the print, so I decided to look at an alternative to the bearing eject holes. Think I came up with a better idea than the side mounts. I made 2-3.5mm slotted holes thru the bottom which should give me enough room to insert an allen wrench in. Coming from the bottom & not the side they are also not visible when assembled.

I also realized after looking at this section why those bearing spacers needed to be shorter. With the tapered resting spot for bottom bearing and rounded edge of bearing it will rest a little higher in the wheel. I have the bottom bearing designed to sit 1mm beyond the bottom of the wheel, but measures .75mm after inserted. That measurement verifies the spacer size as it did come out .25mm shorter.

Plotter test was much better with the wheel spacers than without them. It is still not perfect yet. I am about 3.5mm off at end of plot from where it started. The best I had before was about 12mm. I will reprint the wheel endplates with higher infill to see if that helps. it has a little flex in them at 4 perimeters & 30% gyroid infill. A friend suggested using a yoga mat for the rolling the plotter on, but it was not as accurate as rolling on the vinyl cutting board. Here is the test video running at 1800mm/min.

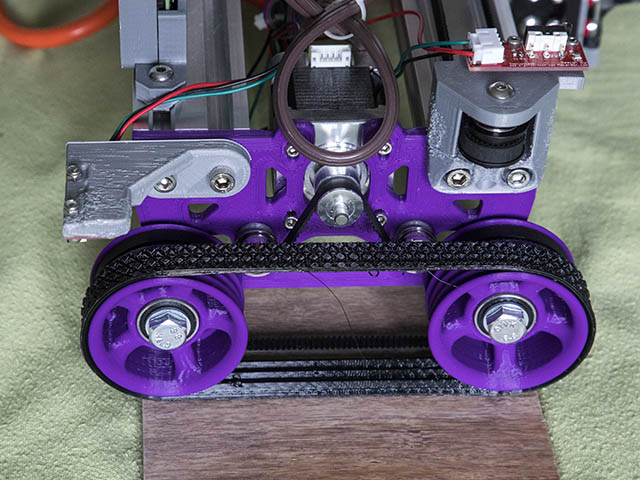

My wife likes purple, so I have some purple filament on hand now. This has no flex at all in it now. I printed with 6 perimeters & 50% gyroid & .24mm layer height. Printing 2nd plate now. If it is still a little off after this change, I will suck it up and make the wheel bearings press fit tight with no access holes. I could always drill out the plastic beside them if I needed to move the bearings to a newer design later. That should be the only other thing I can adjust without adding a wheel guide.

I’m playing with similar “drift” issues right now… it’s not terrible but also not perfect. I think that both tractors/trucks must run EXACTLY PARALLEL to each other… i.e. any “toe-in” or “toe-out” between them will cause “drifting”. My gut feeling is that since our tractors/trucks are not constrained to always follow a fixed path – rail or guide – drift is always going to be an issue… and for any real “precision” a guide of some sort is going to be necessary. I wonder then … should it be called “track plotter”?

You are probably right, but I would really like to keep this plotter unconstrained on the wheel axis if possible since that was my initial intent. When installing the bearings in my latest wheels that have the 2 access slots from the bottom (22.3mm bearing holes), I noticed they were about the same fit as they were with the 22.4mm. Those holes might be hurting my precision. Making those a tighter fit will be the only other thing I can think of to change that might give more accuracy. I will see how the new wheel endplates work first. I found it interesting that my pen was only 3.5mm off at end of plot when running at 1800mm/min & 1000mm/min. The wheel spacer idea you told me about gave me enough accuracy to motivate me to continue working on this idea. I have the wheel stepper motors attached to 2 different drivers & guess they could get out of sync. The 2nd wheel stepper is attached to E0 driver. I had a thought about your rack & pinion track you used on another design. That track would lend itself nicely to be printing on one of those 3d printers that prints on a conveyor belt so there would be no joints. How did it work for you with the joints in that rack? Is there a way to print that track with joints that do not affect the smooth movement along that axis? I have also toyed with the idea bigger diameter wheels, maybe 100mm which I have seen in the other similar designs on openbuilds, but I would have to 3d print the TPU treads for those. I have not seen o-rings that big. Do you think bigger wheels would be any better?

First, I don’t think guides would be absolutely necessary if you’re not doing anything requiring any precision. Sand plotting, sketch drawings, etc should be fine “un-guided” I would think… although I would still want them to track as parallel as possible, to minimize the drift.

I have the motors on my tractors wired in series… ala MPCNC. I’ve never any sync or imbalance problems with them hooked up this way.

Not sure how you might use the rack and pinion idea (as “track” to guide/run on?) but the joints were not a problem at all. I have an Onshape rack design with ONE tooth… which you then “linear array” to the number of teeth you want/need. My printers can only handle a rack section a little over 8" long so that was the longest rack section I could do. On my R&P MPCNC I just staggered the joints on opposite sides and never noticed any issue at all when plotting rulers, crowns, laser engravings, etc.

I’m not sure the effect bigger diameter wheels would have. Playing with my machine as I have been, I have come to the conclusion that this is not the most stable of machines… when I gently wiggle the machine from the top of the Z-axis stage, the whole machine rocks, pretty much in any direction. Anywhere a “wheelbase” could be increased (tractors and linear stages) would help the cause… though it’s probably just fine “as is” if only light loads – pens/markers, needle cutters, lasers, etc. – are all it ever sees.

BTW you are welcome to any of my STL’s if you think they’d be of use to you. IIRC you once mentioned the extrusion “pass-thru” on the end-plates and the Z-axis linear stage… and I meant to offer them to you then but I forgot…

– David

I ran 3 tests today with new endplates without any better accuracy so will reprint the wheels without recess holes & 22.3mm bearing size which fits very tight without the recess bearing eject holes. I ran initial test at 1800mm/min, then 3000mm/min & also 3600mm/min. Interestingly the 3600mm/min seemed just as accurate as the 1800mm/min. It won’t be until Monday or Tuesday before I can run a test with new wheels.

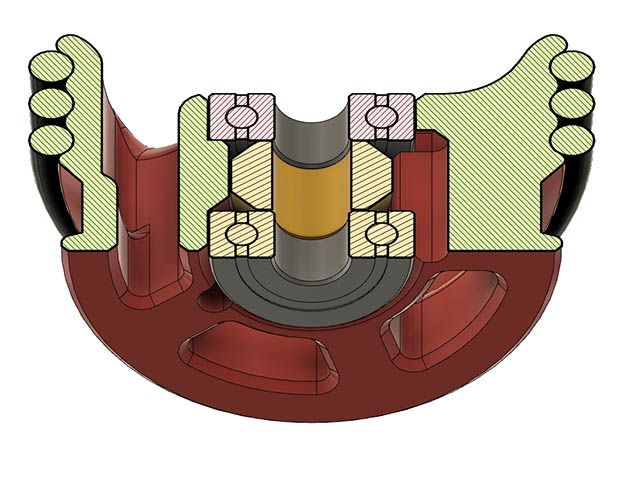

I got the new wheels installed. The carriage belt has a better tension on it than before. I ran it faster today at 4800mm/Min or 80mm/sec and was a hair more accurate at off only about 3mm at the end, but had some pen skips. Skips are probably mostly from the pen not lowered enough. I ran it again at 1800mm/Min and was about 2.5mm off at the end. I really need a better z-axis than the servo. I have a couple of nema17 pancakes now that I can try. I was also thinking today about using tank tread printed in TPU. That would give me more gripping surface. Will have to research some designs for ideas for this. Not sure that would give me anymore accuracy, but would look cool. Here is a video of it running at 4800mm/Min.

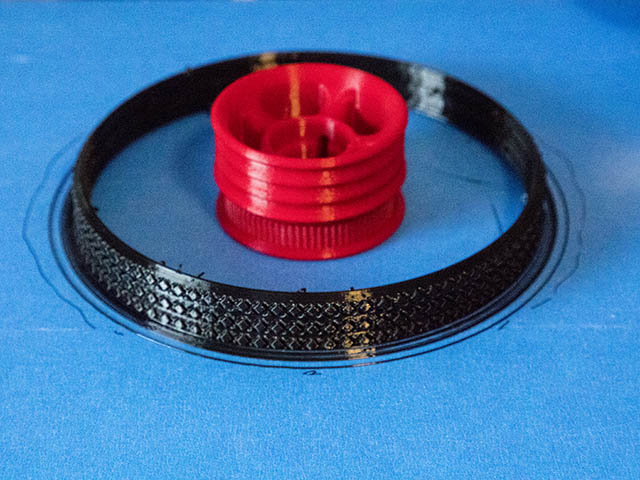

Instead of using tank treads, I had a thought this morning about 3d printing a TPU tire to wrap around both wheels. Not sure whether I can get it to print or not, but would give more surface area for traction if that is the problem with accuracy. A 3/4" thick rubber band on each side would probably be better & just wrap over the o-rings, but don’t have any of those. Looks like a #94 rubber band (3.5"x3/4") would be perfect, but not sure I want to buy a box of 140 from Amazon. Maybe I can find a smaller quantity from somewhere else. #84’s would be the 2nd rubber band choice at 3.5"x1/2". I can find them at a Staples store not too far from here for $2.73 for pack of 45. I might have to go by there. Here is kind of the idea I had for the TPU tire.

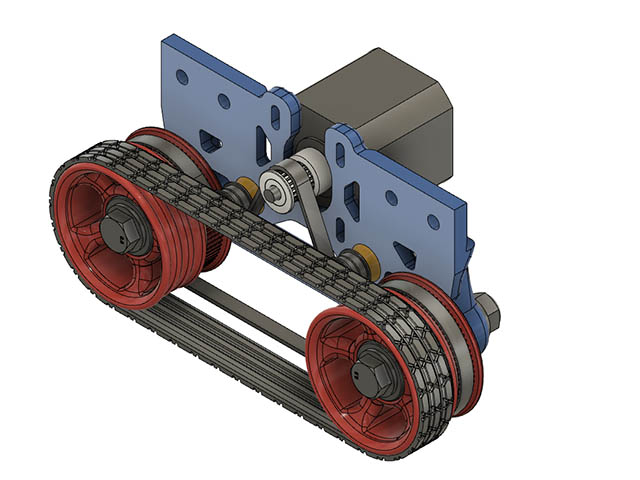

The rubber bands I have are just not going to work. One came off early in the plot & the other came off a few minutes later. I did find some 7"x1" rubber bands from Grainger for $6.55 for a pack of 5. Those should stay on a lot better, but not sure I want to spend anymore on rubber bands before trying the 3d printed TPU 2 wheel tire. It is a 2.5 hour print per tire at 30mm/sec & a few layers into to the print it is behaving nicely.

I added the same tread pattern as my original TPU single wheel tires. It will not be as grippy as the o-rings but with the more surface are touching the ground seems like it should be less slippage.

Not that I believe the rubber bands are going to be best for this application… did you “crown” the wheel where the band rides? If you’ve ever used a band-saw… the upper and lower wheels are “crowned” (rounded and high in the center) and the steel blade/band is easily adjusted to track properly on the wheels. That might help keep the rubber bands from coming off in future tests…

I was slipping the rubber bands over the center o-ring. I also tried taking the o-rings off & putting the rubber band directly on the wheel, but didn’t seem like it was going to work, so I didn’t fiddle with it much. Putting a few of them on there might work, but didn’t bother. I will try the TPU wheel before playing with the rubber bands again. They will not slip off as they are caught in the grooves. Hour into the print & still looking good.

After fitting the 1st TPU 2 wheel tire on it seems a little loose and probably should be printed in circular pattern instead of the way I printed it since it has kind of 4 creases where it is tangent from the circle to the straight line. Should also be a little shorter perimeter since it stretches. That is probably why a tank track works better than this style because it is difficult to get it a tight fit. Perimeter going around both wheels of where the center of the O-rings are is 415.24mm which should give me a diameter of 132.175mm. Since I can stretch tight about a 16mm diameter around motor shaft that comes out to about 421mm perimeter, so I will shorten it the diameter of the tire to be 6mm (1/4") shorter perimeter. I will round down to 130mm diameter. On a positive note that is 6mm less length of tire to print. Still might not work, but worth taking the idea a little further.

This looks like it stretches more than a 1/4", but that is what the perimeter measures. I might go 9mm instead of just 6mm.

I adjust my 3d printer some yesterday & it is happier printing TPU today. I still have about 3mm difference in height from gantry from one side to the other, but can’t find what is out of square. I did find one M3x30mm bed adjustment screw where the threads were stripped. Don’t think I have ever stripped threads on any of that stainless steel hardware. I managed to get the screw out without getting my dremel involved & is easier to level the bed now. Adding some glue stick to the bed was the final thing that helped getting the tire to print.

The tire print has an outer diameter of 132.3mm. I still have to cleanup the inside of the tire from the nozzle oozing. I wanted to fit in place before starting the 2nd tire print. Hopefully can test it tomorrow. Gripping wise, the o-rings still seem better on the cutting mat surface I am using to roll the printer on, so it may not be any better.

TPU tires did not work as well as o-rings on the cutting mat surface which I was expecting after feeling the grippiness of the 2. A more textured rolling surface would probably help or maybe the wide rubber bands, but that is all I am going to do with this until I get another inspiration. As the test goes, the wheels actually started going crooked after a while which that has not happened since adding the bearing spacers. I was also off 11-12mm at the end of plot. The TPU wheels would probably work pretty good on concrete or asphalt. Maybe I will try it outside sometime. I have an outlet near the driveway. Ooh, and I also have some chalk I bought from Dollartree.

Anyone have suggestions for a 14"x 6 foot or so long pattern to draw on Concrete? Looks like I will need a better grade of chalk before trying this. The Crayola chalk that dollartree sells breaks too easily.

This looks like the chalk I need. https://shop.crayola.com/toys-and-activities/sidewalk-chalk-12-count-5120120002.html Think there are a couple places locally that sell it in 16 & 24 color packs.