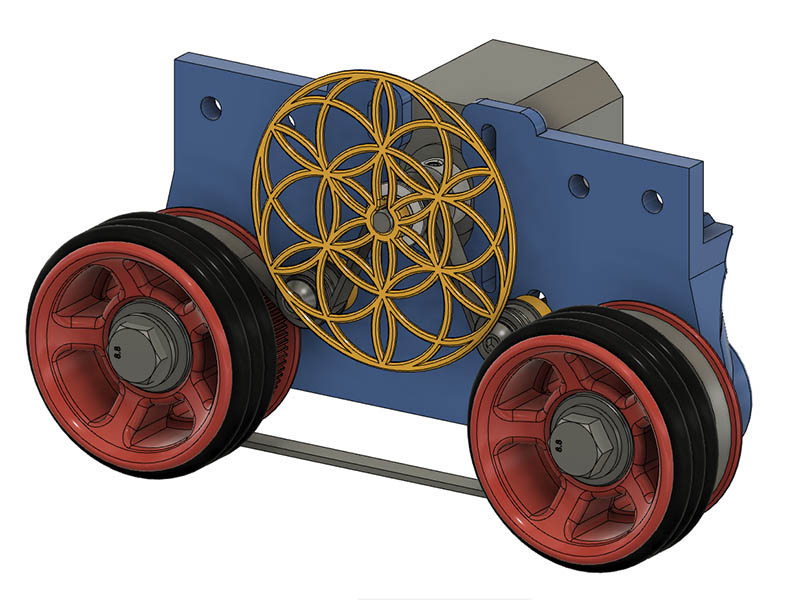

Since I was on a flower of life theme, I had to make a flower of life visual. Think I have some yellow filament to print this with. I was originally going to use a magnet to hold in place, but then realized the motor shaft wouldn’t stick to it. I should be able to just press fit it on there with that slot.

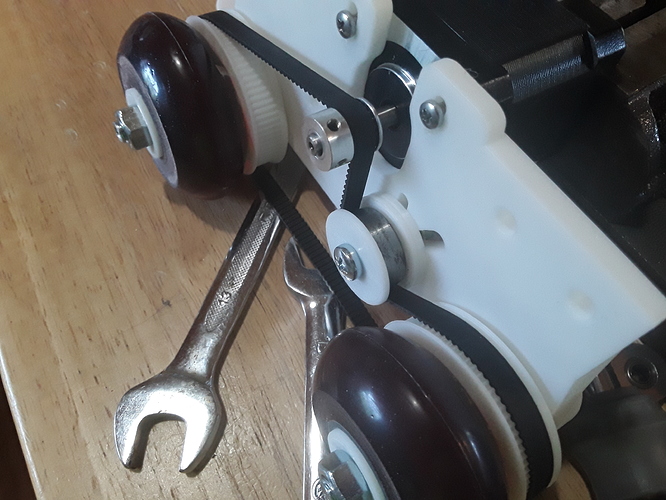

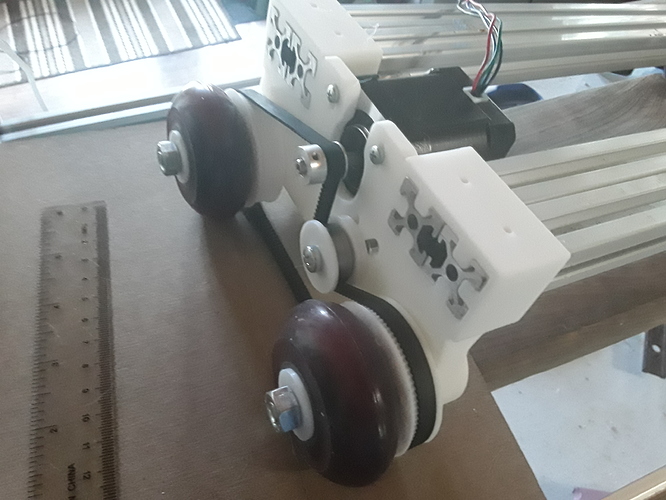

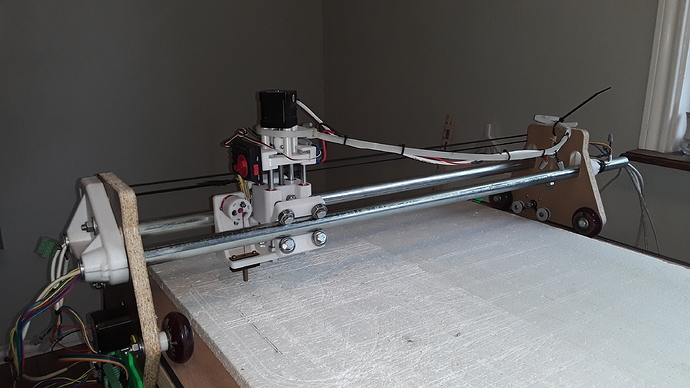

Here is my latest video. I am using all the new parts except the Carriage motor mount and I couldn’t use that because my belts were not quite long enough. After getting the 1st 2 wheels with 78T printed, I couldn’t get a descent print of them without webbing in the teeth, so I used a 76T wheel on each side to which shouldn’t make a difference in the printing. Looks like I need a little rougher surface for the wheels to roll on. I have some left over 5"x6’ bamboo flooring which feels like it might have just the amount of roughness on the backside for the wheels to roll on. I will test that next. After the next test, I will put the 1 meter width version together. I added a motor visualizer to the wheel motors & since I was drawing flower of life designs, it made only sense to make it look like that. I think it does make it look cooler while it is rolling.

An update…

On a much slower boat than normal… my 444mm belts were finally deemed “lost at sea” by the shipper. While waiting on the belts, I had pretty much piled everything in a corner and gone on to other things… and it didn’t look as though a rolling plotter was in my future anytime soon. Then a few days ago, mysteriously, a small package arrived in the mailbox… and, bored as I was, I was looking for something new to play with.

So I started playing with the endplates I had already printed… and started modding them to take advantage of parts in my stash. Wth zillions of 608 bearings on hand, I elongated one idler bearing slot to allow a single 608 idler to replace the two-bearing idler setup of the original endplate.

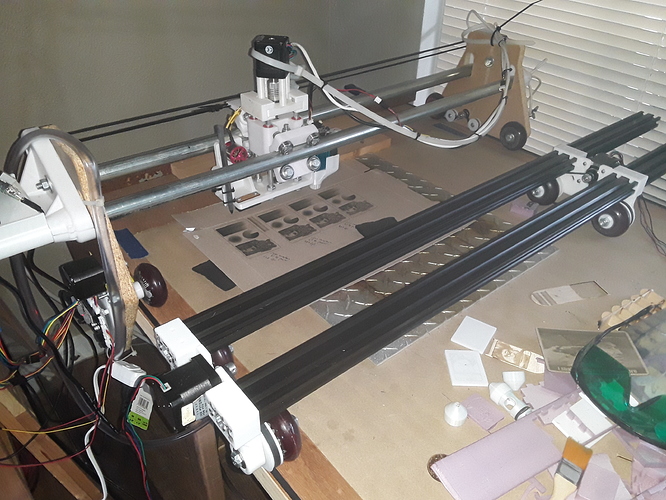

With the belt routing looking reasonable for now, I then took a look at the extrusion to endplate connection. I have a couple of 1000mm 2040 extrusions that I’m reluctant to cut to length until I know more about how I might use this thing… and decided I’d really like to try setting it to the same width as my FoamRipper gantry and work surface. So I reworked the extrusion “shelf” to allow the extrusions to “pass through”, for width adjustment and even endplate reversal (wheels inside or outside) if necessary.

So, now I’m printing a second endplate to match and can begin to think about getting this thing wired up and moving. I’m hoping to honor Dave’s mechanical design for the remainder of this build as much as possible… until I know more about how I might use it.

As my eventual “use case” differs from Dave’s, I’ll start another thread as this thing starts taking shape and moving. I know Dave has designed and demo-ed the rolling plotter to run on the floor (or any flat surface) plotting on paper and drawing neat patterns in a sandbox… but there is so much similarity to my FoamRipper’s gantry – driven skate wheels vs. free-wheeling and LR-style belts – that I suspect I’ll be running it on the interior door work surface of my FoamRipper, as a new extrusion-based gantry.

Thanks, Dave, for a really neat, new, fun, play toy!

– David

Looks cool. You should be able to run them both on the same table that way. Put a pen on one and a needle cutter on the other, and then synchronize them to make planes with penguins on them

You fool! Penguins aren’t meant to fly!!!

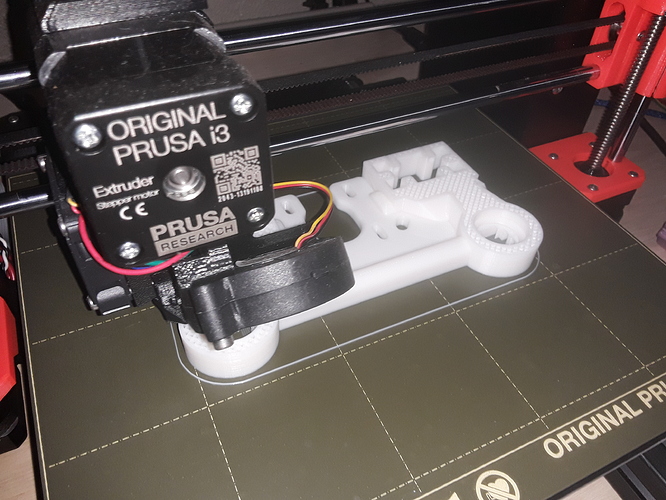

Glad you are making progress. My biggest problem with my design so far seems to be the wheels binding occasionally, but do not see when it happens. Initially I had really good results, so I am thinking those wheels just need to be tightened just the right amount. I tried some newer bearings, but not sure they were any better than what I had. Lately I have been focusing on getting better prints from my 3d printer. I am getting a little bit of cob web in the GT2 teeth on the wheel & adjust heat temperature or retraction has not helped. I just finished swapping my electronics board on that printer from the Bigtreetech skr 1.3 with TMC2208 & LV8729 on E0 & Z to the Bigtreetech skr 1.4 with all TMC2209 in Uart mode & not sensorless homing. I have the hotend fan plugged into E1 & Bigtreetech changed the +/- orientation of that plug between the 1.3 & 1.4 board for some reason & I missed that. Fan still seems to work, so hopefully I did not hurt that fan. I can now try linear advance with this board & maybe that will make a difference. TMC2208 drivers seemed to not work properly with linear advance.

I had the same problem initially but printed a spacer to go between the twin 608 bearings’ inner races in the round section where the bearings seat. The spacer allows tightening the axle without pulling the inner races toward each other… and thus binding the bearings up. I forget the exact thickness but will check if you determine that’s your binding problem as well.

If you scroll back to message 114 there is a section view showing, my wheel has a center portion that touches the outer walls of the 2 bearings, but keeps the inner races free. I still have my previous wheel design on my printer, so these newer ones might work better. I was just hoping to get my printer fine tuned a little more before printing the new versions. If I get motivated again, I would like to revisit the idea of the hamster wheel drive.

If this is the picture you are referring to…

I think this is the problem. If you take thumb and forefinger and press heavily on the inner race on each side of the wheel, you will be forcing the inner races toward the center and eventually bind the bearings. The spacer I’m talking about sits between the bearings and only touches the inner races… and keeps them from being forced out of alignment with the outer race when the nut is tightened fully.

Here’s a better explanation and where the above picture is from.

Or, maybe I’m just misunderstanding the whole thing? Wouldn’t be the first time…

I appreciate you pointing that out. Holding 2 fingers on there was not enough force, but when putting a bolt on there & tightening that does appear to be the problem. I had seen those spacers that Ryan sells for the lowrider & wondered if I needed something like that, but never pursued that thought stream. Guess I will make a 3d printed spacer to see if that fixes the problem.

You’re welcome. The length of the bearing spacer has to be just right, filling the space between the bearings when fully seated in their pockets… not too long (keeps the bearings from seating fully) and not too short (same as no spacer).

The other endplate finished printing so I quickly assembled it and slipped it onto the rails and set it roughly in place on the FoamRipper, where I see it eventually going.

Thanks again, Dave… for a fun design and build.

– David

It took me a couple of test prints to get the right dimensions and looks like it should work. I have 2 of the new wheels done, so will have to print the other 2 tomorrow. Looks like you made the end plates so they can be a variable length. That’s a good idea. I look forward to seeing how your progress goes.

I had about 20 of those spacers printed, and in a box somewhere. I kept on being convinced I had nailed the size, and printed 8 more, and then they were just a little wrong, and I had to make another one. I think it took long enough that the metal ones I ordered finally came in, so I didn’t even use them.

I almost forgot… I made a really neat discovery on this last round of endplate modifications.

I often have an existing STL and need to alter it in some way. For simple mods, TinkerCAD can be really handy. For others, not so.

My preferred CAD is Onshape. But importing an STL into Onshape gives a “mesh” that can be good for picking off reference points and measurements… but can’t be altered directly. I have found that STEP files are quite good however… when they exist. So, I googled “STL to STEP conversion” and found that FreeCAD can often pull this trick off successfully… as well as Fusion360 (but this isn’t a path I’m willing to take). Turns out, FreeCAD is now available as an AppImage… which for this Linux user means “download, make it executable, and launch it”. Even on Chromebook with Linux(beta) enabled… YAY!

Anyway, launch FreeCAD, open your STL, switch into “Part” mode, Part->“Create Shape from Mesh”, and then File->“Export” the resulting “shape” as STEP. If all goes well, you now have a “solid model” to import into Onshape.

I did this conversion successfully with Dave’s “End_plate-Rev6” STL and then altered it to accommodate the adjustable extrusion features of my final(?) endplate.

How neat is that??? – David

I was thinking that converting STL to step might be a really great AI project. There are a lot of free models with .step and .stl files, to train from, and it would be pretty good at finding things like curves, chamfers, and maybe even compound surfaces. I’m not an expert at machine learning, but it seems like a cool project to learn about it.

Too bad I am so busy making snarky comments in the forums. No rest for the wicked.

Good and bad news on my spacers. They fixed my sticky wheel problem, but since I have fine tuned my printer it seems my tolerance fit is better, so now the wheels spin nice but are a little wobbly. I should have done another test fit of those bearings before printing all 4 wheels. I was using 22.5mm for the 22mm OD bearings, so I will try 22.3mm now with 30 minute test print.

These spacers reminded me of this guy’s video.

I don’t know what he is thinking about, but my son will randomly yell, “Spacers!” with a spanish accent. We love watching these videos. I wish there were more people speaking english with legitimate accents in shows when I was growing up.

Yeah, love Ivan’s videos… spacers, Spacers, SPACERS! I use tons of spacers in my designs… and I guess that’s the norm rather than the exception. Thank goodness for 3d-printers!

Test fits are IMHO a necessity… doing one right now in fact to accommodate an embedded 608 bearing in my wheel sprocket. I’ve noticed a very slight required tolerance difference between the MK2S printer I handed off to SIL and the MK3S I have now. I’ve always gotten nice snug fits with just 0.2mm or so on bearing fits with the “old” printer… still not sure what I need with the “new” one

I found a problem with my new 78T wheels today. I had the bright idea to take out 1/3 to 2/3 of the teeth since the belt connects with about 225 degrees of the wheel. That still gives me 17 teeth grabbing the belt if I take out 52 of the 78T. The problem came in when I was taking out the teeth & noticed I missed a change with the circular pattern of the one tooth profile. It was still set to 88 instead of the 78. Glad I caught that before releasing those new wheels. Interesting it did not really cause a noticeable problem when running the plotter, but definitely was a problem that needed to be fixed.

The 22.3mm hole seems to tight, so am going to try 22.4mm. Usually .2mm clearance all around works well for me also & 22.4mm gives me .2 mm all around. Not sure if you would call that .4mm clearance or .2mm clearance.