MPCNC Experts, Help Me Choose My Next Chapter

MPCNC Experts, Help Me Choose My Next Chapter

Hi everyone ![]()

I’ve finally reached the point where I should ask the experts instead of endlessly thinking and printing test parts ![]()

A bit of backstory

About 5 years ago, I bought an MPCNC in a way that was much more impulsive than rational. At the time, I honestly didn’t know exactly what I wanted to do with it. What followed was a huge learning journey — mechanics, firmware, calibration, mistakes, fixes… all of it.

Fast-forward to today, and I’ve come to a very clear realization:

I mainly want to use my machine for drawing and painting.

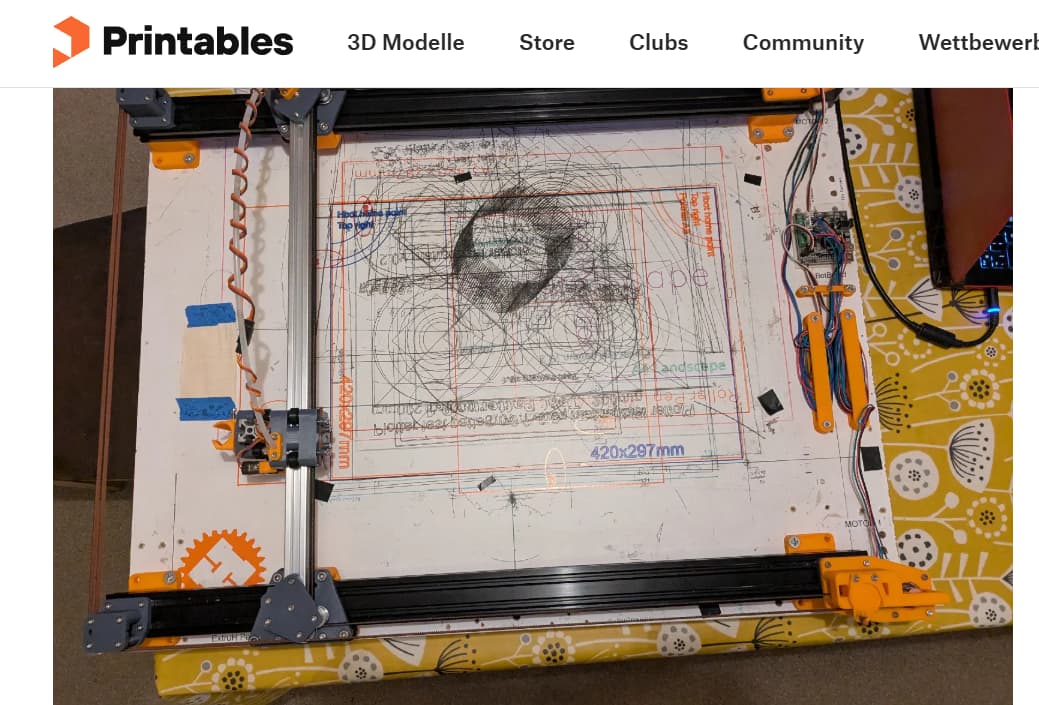

Over the years, I’ve developed my own tools for dispensing paint, and that is now the core purpose of this machine. In that sense, I feel that my current build could be optimized more for my use case rather than following the original MPCNC design.

My current setup

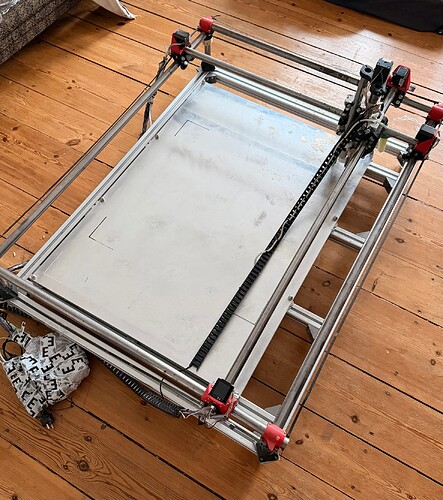

As you can see in the pictures, my machine sits on a very solid, mobile frame with a large aluminum sheet as the working surface. The sheet is carefully straightened and leveled, which is absolutely critical for me — dispensing paint is basically like doing a perfect first layer of 3D printing, but on a very large scale. I’ve gone as far as Measuring the table height at many points and automating calibrating Z per drawing G-code to optimize the height instability issues![]()

The machine is roughly A0 paper size, with dimensions 1200mm × 900mm, so it’s quite a big build.

As you might expect from a very large MPCNC, I’m facing the usual challenges:

-

Flex and rigidity limits

-

Long belt behavior

-

Squareness and alignment drift

-

Speed limitations once things get large

Here are some pictures of my build and snapshots of my tools and process.

What I want to improve

I’d love to upgrade rather than start over. The one thing I’m sure of is that I will reprint most of the machine, but now is the perfect time to pause and think strategically.

What matters most to me:

-

Speed

Speed -

Perfect pen alignment and consistency

Perfect pen alignment and consistency -

Reuse as much of my existing setup as possible

Reuse as much of my existing setup as possible-

Frame

-

Electronics

-

Motors

-

Screws, bearings, hardware

-

-

I’m totally fine printing new parts and ordering some hardware

I’m totally fine printing new parts and ordering some hardware -

I don’t want to start a huge new project or design a complete system from scratch

I don’t want to start a huge new project or design a complete system from scratch

Where I’m stuck (Primo vs LowRider vs ZEN XY)

Since my machine is based on a 2016-era MPCNC, I’ve been looking at newer designs:

-

MPCNC Primo

(maybe with shorter legs / reduced Z)?

(maybe with shorter legs / reduced Z)?

-

LowRider V2

-

LowRider V4 looks amazing, but feels like way more than I need for drawing

-

ZEN XY also seems promising

if it had just a bit more Z travel, which would make it ideal for my A0 plotting setup

if it had just a bit more Z travel, which would make it ideal for my A0 plotting setup

At the same time, I feel like the Idraw-style approach (simple, rigid, drawing-focused) makes a lot of sense for my use case if it could sit cleanly on my existing structure.

So now I’m wondering:

-

Should I upgrade to Primo (maybe with shorter legs / reduced Z)?

-

Should I go for LowRider V2, since rigidity and large format matter in my case?

-

Could ZEN XY with more Z be a better fit for my purpose?

-

Are there any community-proven modified builds optimized for large-format, high-speed plotting that I should look at?

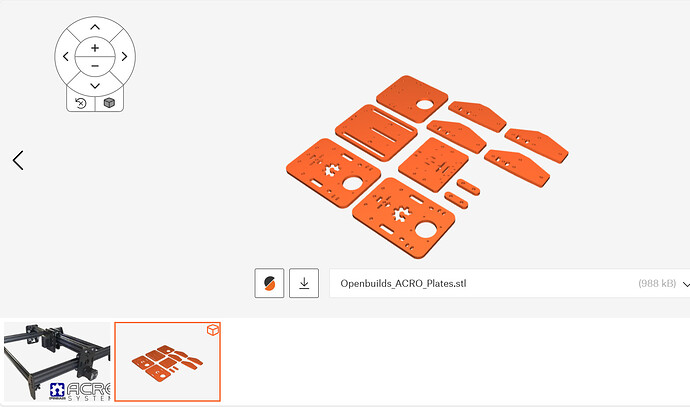

I’ve been very inspired by some community upgrades I’ve seen ![]() but before I start printing an entirely new set of parts, I wanted to ask the experts first

but before I start printing an entirely new set of parts, I wanted to ask the experts first ![]()

MPCNC Primo // Fastest CNC // FluidNC

Given my use case (large format A0, 1200mm × 900mm, paint/pen drawing, speed, reuse of MPCNC hardware, minimal self-designing):

Which V1 design — or which proven variation — would you recommend?

Any guidance, build references, or “don’t do this, I already tried” advice would be hugely appreciated.

Thanks a lot, and huge respect for the work you’ve all done on these machines ![]()