No, directly from BigTree-Tech.com / Biqu3D.com (BTT official website). Ordered July 09, so recent, and certainly after they knew of the issue.

My original board was way past any reasonable warranty period, and I F’d up that board attempting a component replacement (unrelated to the endstop issue), so I ordered from the manufacturer directly to take advantage of free shipping to Canada (shipping from V1E to Canada is not inexpensive).

My guess is that most people repair them themselves (cutting LEDs, adding resistor pigtails or soldering to the board) without involving Ryan. That’s what I did (both times), and that is what I have seen multiple people post on this forum as having done. So he probably doesn’t have accurate stats as to total failure rate, only for those that were sent back to him by people that didn’t want to deal with the issue themselves.

Well my experience is that the board may seem okay, until the conditions (wire resistance, wire length, etc.) are such that the circuit no longer works. In fact, on my first board, after my wiring changed, the board would work perfectly fine for 5-10 minutes with no problem, then Y2 would intermittently fail to recognize the endstop (while having the LEDs asserted). The second board was similar, with Z2 working fine about 80% of the time. And no, not a loose connector.

I’m not sure where I would find those details…

Anyway, let’s not derail this thread further.

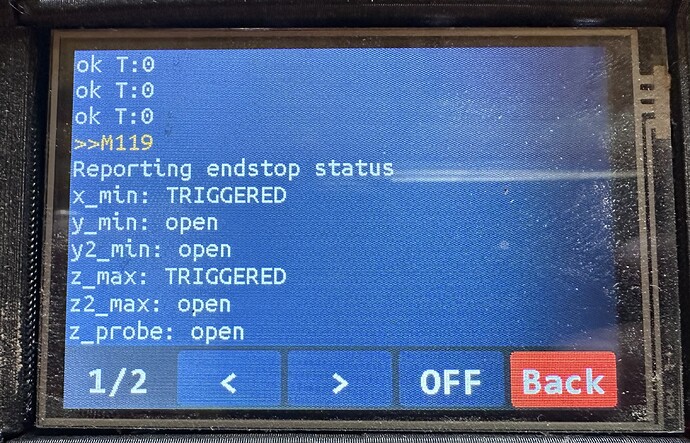

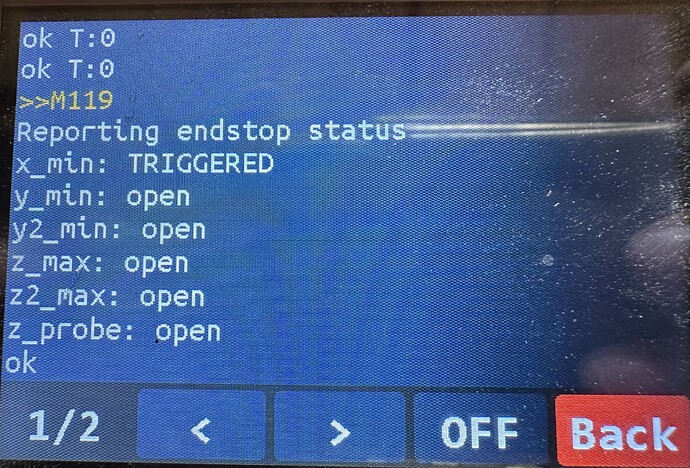

To answer the OP’s question, it is possible that you have the SKR endstop issue at play here. As @MakerJim mentioned above, one way to know is to do a M119 command when the switch is asserted. If the problem is not intermittent, this should tell you what is happening.

If the problem is intermittent, you may find that the Z motor runs through the endstop until the motor starts skipping steps, then shuts off and drops, and then the M119 shows ok after the movement stops.

If this happens, there are a couple of possibilities, one of which is a bad connection (did you remove the plastic JST pieces from the terminals?), the other of which is the endstop.issue. If you are certain that the LEDs assert each and every time, then it probably isn’t loose wires.

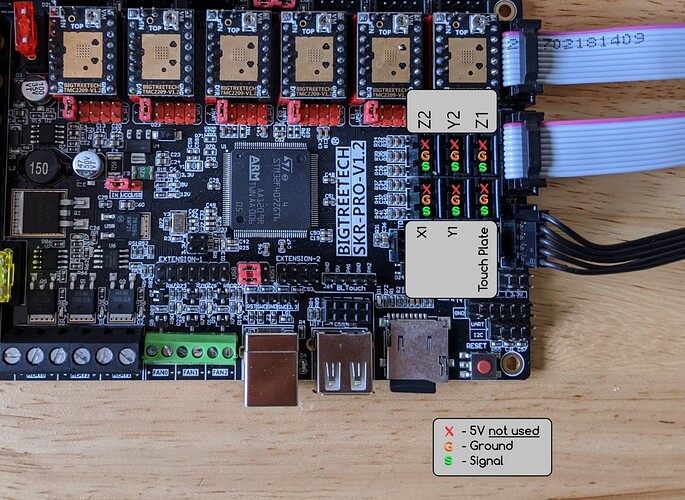

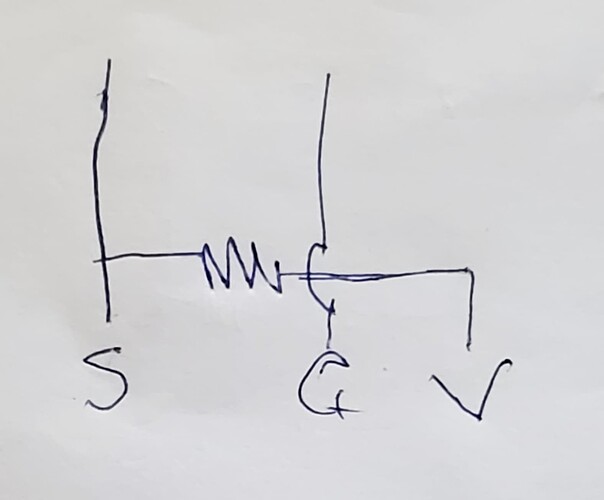

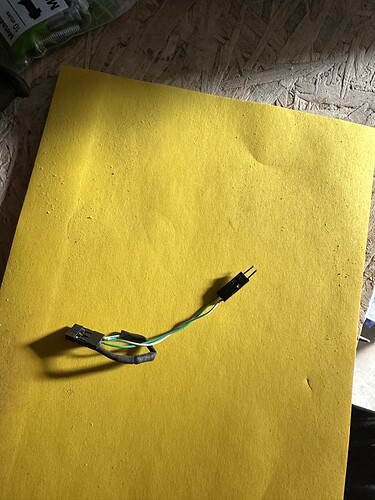

If you think that it is most likely the endstop issue, try adding a 1-1.5 kOhm pigtail (3 pin female connector on one end with a resistor between the two outer pins and wires from one one outer pin and center pin to a 2 pin male connector on the other end. MAKE SURE that the 3 pin connector is attached so that only the resistor (and not the resistor and wire) is touching the VCC pin on the board, or you can permanently damage it.

Alternatively you can solder a resistor to the underside of the board, or cut the trace to the LED (either of these options will void any possible warranty claim).