First post of topic.

Ordered some V1 parts today, starting to gather stuff up for my build.

First post of topic.

Ordered some V1 parts today, starting to gather stuff up for my build.

That printer looked pretty appealing at RMRRF. I see you caught the bug.

Hey @MakerJim. Have you had a chance to see what size you want to make your build and if you will need different ABC bed plates?

Ahh, the misery of having lots of choices ![]()

I’m still on the fence, because:

I tried to open up fusion360 today on the windows box that I keep around for that purpose, and it isn’t happy with me. I go through this it seems once a year when I try to use fusion. So I’m still thinking about that and also debating whether I even want to hassle with it if future machines will be in Onshape.

I know that I really, really like the way some folks have been putting electronics on DIN rails at the back of their builds and I plan to do that even if the machine is otherwise just like the build Ryan had at RMRRF. Mike’s build exemplifies what I think I may want to do there.

More on my CAD thoughts that in the ‘which cad is for me in 2024’ thread.

I have a pile of my own various parts that I could build a printer around, but also an amazon cart ready to click buy on to copy what Ryan build. How’s that for not answering your simple yes/no question? ![]()

To combine this with a bit of an update, my V1 parts for the V5 and a LR3 are expected to arrive on Monday if the tracking is to be believed.

My parts bin of LR3 items is growing more full and most are printing beautifully.

I haven’t started printing V5 parts yet.

But I’ve got one part that has repeatedly spaghetti-ified.

The X Drive Mount.

It pops off the bed when trying to close a set of holes as shown.

It fails with and without a 4mm brim.

Probably a PLA temp tuning issue that I could fix but I’ll come back to it.

Probably should have put the update in my LR3 thread. Oh well.

Yes this is a VERY good idea. I did it as well as @Michael_Melancon. He went a lot further with the planning than I did. And I have already laid out most of the back panel for when I convert the V4 over to V5.

Man that’s odd. I have never once had an issue printing an LR3 part. I’ve broken them after the fact but they always print great!. What layer height are you printing at??

LOL its all good. I still have another few weeks home so there is time. I was mostly just curious. I have all the dead boards ready to go and the parts I ordered from Aliexpress. I might also send you one more SKR if you want to mess with yet another one. Its still working, actually running on my V4 right now. But it has 2 mosfets that are always on 100%. Up to you if you want to mess with that one as well. I do still have 1 more spare SKR LOL. But before I send this working one I will hook it up and test it out to be sure. That way I’m not down a printer while you work on the boards LOL

I finally decided that I’m going to build my V5 pretty much the same dimension as Ryan’s V5 that was at RMRRF. I’m going to change the back panel to have DIN rail and electronics routing as described up above.

I also made a little progress as I did a bit of cleanout in my storage facility so I could clear up enough of my garage to work on a table for my LR3 build. I should rant a bit about the insanity that is having a storage facility- but maybe that’ll go in the LR3 build thread.

In so doing, I came across a tote full of the Misumi 2020 extrusions from my old AO101s that I took out of service and disassembled a couple of years back. I think these will work to be cut down for some of the smaller V5 extrusion lengths. I also found the 10 pack of 1 meter ZYLtech extrusion that I originally bought when I set about to build a V4 repeat. There’s also some PLA parts I need to recycle because I was originally going to build an aluminum ultimaker clone before I decided to build the repeat V4. Also a big pile of ABS to recycle from the AO10x frames.

I’ve just about finished giving away the personal pile of RAMPS 1.4 boards and reprap graphic LCDs that I amassed while maintaining the Lulzbots for the local makerspace.

Those AO101s were quite an interesting story. They were Lulzbot factory print farm machines from when Aelph Objects (Lulzbot) were in Loveland CO. When the TAZ line came out, they built out a new army of TAZ build farm machines, and the ancient AO10x printers got donated to local makerspaces and community. We had a small farm of those at the local makerspace, and when we upgraded we let members buy the AOs. I ran two of these for many years.

I can’t find a good picture of mine at the moment- but they looked like this:

I also decided that when I get my first V5 build completed, my TAZ5 is going to get rebuilt into a repeat V5 as the next printer change.

I’ve also started prepping for Klipper and have questions. I do have a bunch of RPi but also during the dry times picked up a couple of BTT CB1 and carriers. You can see a couple in printed mounts that can accept DIN clips on the bottom.

Does anyone in the community have experience putting Klipper on the CB1s? I’m debating hard between that or a Pi 5. The 8Gb Pi 5 almost seems like overkill for a repeat running Klipper, but the CB1s run a funky BTT Debian variant.

I have another batch of Amazon stuff in my cart and will finalize that tonight. Looking at terminal blocks and DIN rails but haven’t decided I like the various options.

I also did a bench test of the SDR pro V1.2 and BTT TFT3.5 that I bought from V1 for the original repeat V4 build. It works great. I also got one of the SKR pro 1.2s that I repaired ready along with at TFT3.5 that I’m in the process of repairing. I want a bench testbed as I go and want to play a bit with Klipper installs.

Much to learn.

I need to finish my LR3 so I can cut panels for the V5- so tag teaming activities between the two build threads.

I have the Manta M8P running with a CB1 on my V5.

I’d recommend using a Pi 4 or Pi 5 instead.

The CB1 is “capable” of running Klipper, but it’s performance is roughly the same as a Pi 3.

I have an Ender 3 Pro running Klipper with a Pi 4, and it is noticeably faster.

Boot time:

Ender 3 Pro with Pi 4: 28 seconds

V5 with CB1: 58 seconds

That’s the time it takes from the time I hit the power button, until KlipperScreen is ready for me to use.

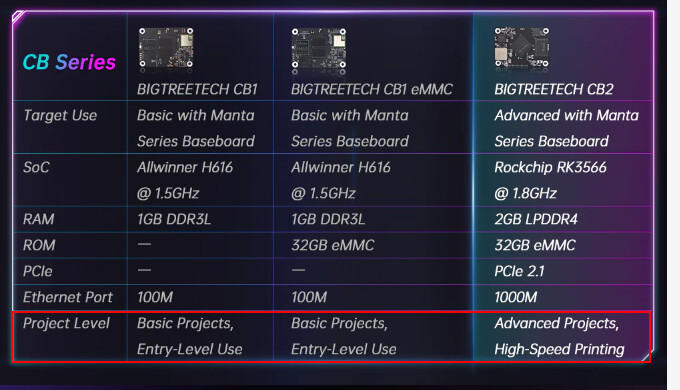

BTT has recently released the CB2, which should be closer to a Pi 4 I think.

They even started marketing the CB1 as “Entry Level” now

I also have WiFi problems with my CB1. It connecting is unreliable, and I’m pretty sure it is set up to only connect once, and not retry if the connection fails.

Any time it gets disconnected, I have to manually go reconnect it through KlipperScreen. My Ender with Pi4 is farther away from my router than the V5 with CB1, and I have no connection issues with it

I run the CB1 on a M8P as well. It does take longer to start up but other than that I don’t really notice much difference. But I have another printer running on a 3b so I guess I’m used to it lol. I did pick up a M8P and CB2 to put on the V4 when I swap it to V5 so we will see then how much better it is lol

The slowness is a mild annoyance that can be overcome, but the real question is whether @MakerJim will hard wire the connection as you did, or not.

If he intends to use WiFi, I would be cautious. There is no shortage of people on the web complaining about wifi issues with the CB1.

After reflashing it 3 times, replacing the CB1 with a new one, and trying to bypass their wifi config to set it up directly in Linux, I still had issues. I reached out to BTT, and their response was “try re-flashing it”, so I gave up. I currently have a 40ft ethernet cable strung across my house to connect my printer until I decide what I’m going to do next.

I have a larger external antenna on the way to see if that helps.

I have the CB1 on both my V4 and my Ender3 with the Manta EZ board in it. The Ender comes up quicker but it is using the standard display vs a full graphical one.

Have not had any serious problems. running them. I like the compactness of the Manta boards.

I DID add an external antenna to the MP3DP V4. Made a huge difference in WiFi connectivity. Used this one.

https://www.amazon.com/gp/product/B07PBFKJSN/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I ordered a very similar one…or maybe the exact same one by a different “Brand”

Probably the same thing. Mine had a little longer pigtail on it but my board is mounted underneath my printer.

Thanks for the inputs.

I’m going to use the CB1s on older machines as I retrofit my older surviving stuff up to Klipper.

I’m going to grab another Pi 5 for the V5 build.

2020 extrusion cutting question- I have an older 10" blade chop saw that I use a lot for dimensional lumber. Is there a specific blade or blade type that folks are getting good results cutting extrusion with?

I didn’t change my blade. I used the same blade I used to cut everything else (maybe 24T???) and got good enough results even cutting 6 at a time. Just go slow.

Same. Standard blade on my chop saw that I cut everything else with. I also did the same taping any pieces that are the exact same together. Took a blades width off one end then pull my measurement and made the Final Cut. That way any minor amount of error was the same across all of the pieces. Also used a cut calculator to figure out how to lay everything out. I set my kerf to something like 20mm and cut all my pieces long so that I could tape them together and do the actual dimensional cut.

opticutter.com

opticutter.com

Online linear cut calculator designed to find optimal solution for cutting linear material with maximal material yield. Try the pipe or lumber cut calculator!

I used the same blade I used to cut everything else (maybe 24T???) and got good enough results even cutting 6 at a time. Just go slow.

Thanks. I’ll find my other blade. There’s a fine finish blade on the chop saw at the moment.

Good tip aobut the blue painters’ tape. I have lots of blue painters’ tape.

I also did the same taping any pieces that are the exact same together. Took a blades width off one end then pull my measurement and made the Final Cut. That way any minor amount of error was the same across all of the pieces.

Great suggestions. Thank you.

Thanks also for the cut list calculator link.

I’m running a CB1 on one of my printers and have found it runs well for me. I am using an external antenna with mine.

BTT has recently released the CB2, which should be closer to a Pi 4 I think.

Interesting that the CB2 has an RK3566.

That means it should support many other commodity Linux based OS besides the BTT variant.

The H616 was something of a funky animal and hasn’t received mainstream support.

I think I’m going to go with a Pi 5 on my V5 printer but am going to use the CB1s as I convert some of the older machines over.

I’m planning to jump to Klipper on all the printers that I currently run Marlin in.

I just got 2 pi5’s and they are soooo fast!! get the fan.