No doubt. I was not suggesting 1/2" for this, but merely pointing out they offer it. My first CNC client job with my LowRider was made with it (at the client’s request).

That place is sooooo much better than what I have around here, they really need to move into Cali. Each visit to Mrrf, I always wandered around Menards at least once.

No menards in Colorado. We do have a murdocks. And further north (maybe near loveland) we have Jax.

I did spend enough summers in Nebraska to know the jingle.

I was very happy when I discovered a town close by has a Menards next door to a Harbor Freight. It also happens to be across the street from the best authentic Chineese food we have around here.

I’ve been doing a lot of 3d printing lately, which has me itching for a new printer again. Do we have any type of doc file created for a ‘how to build’ one of these guys yet? Even if it’s a beta document or something that I can be pointed to to wrap my head around the process without having to read all the build threads?

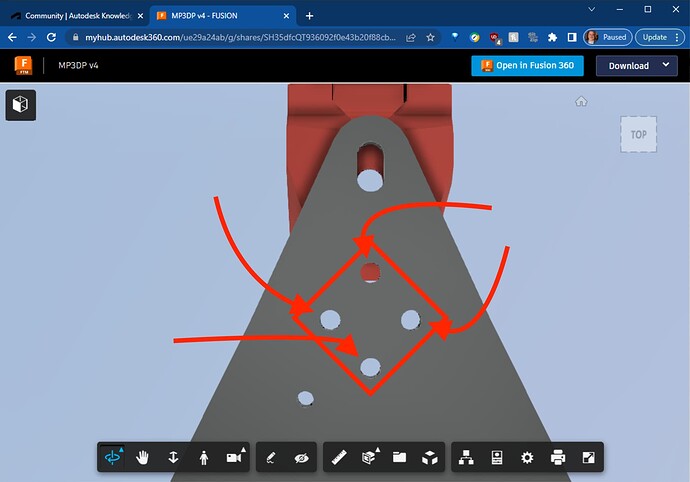

I have a lot of pictures and a how to edit the CAD in the docs, MP3DP v4 - V1 Engineering Documentation

I also have some notes to add to the docs, but I am not done with my paneled version yet so I have been focused on that.

Crop circles, No idea where they came from.

Strain relief for the bed wires…but I think Dan suggested it, I also ran all three of my Z steppers through that this time, and it was great. I had very little wire routing to do.

Yeah, I used those holes for zip ties to route wires. This time, since the Z motors are on the bed, I ran all of my motor wires to the bottom side, and the bed wires to the top.

Man…all of y’all with your clean pretty wiring talk. Making me feel bad for how crappy and all over the place mine is LOL. But keep talking about it. Will be nice having all the tips and tricks when I do go to do it LOL

Should look up cable lacing…

That’s a negative. My dad until he retired worked installing electronics in AT&T offices. Mostly power wiring. They had to lace everything and he would complain about it constantly. I saw a lot of it and while it looks great I want no part of actually doing it LOL.

Ugh. My boss figures that the server room should be like that, forgetting that the company didn’t want to actually install all of the switch gear that it would take to allow all of the network ports in all of the offices to be connected simultaneously, which of course means regularly moving network cables from one port to another one. No matter how neatly you wire it up on the first place (and I’ll be the first to say it wasn’t that neat,) it looks like a tangled mess PDQ.

Damn it. Why does that have to look so much better than zip ties LOL

It’s not too bad for one umbilical cord. Try doing that for 100. ![]()

I like wax string over zip ties. But I am not that neat, so it looks messy. I need to learn the way Barry has done it.

How is your cord sticking up so well? Mine just flops over. It has a dozen wires, the ptfe tube, and the filament.

I second this question