I tried to open the latest Fusion 360 file for the printer in Fusion, and struck out. Apparently my Fusion install is not the latest, so I’m not allowed to open the files. Also my laptop / MacOS is too old to install the latest version of Fusion. So, I am not able to edit the parameters and not able to open or edit the F360 file(s). I was able to download and open the SketchUp file, but obviously there would not be any parameter-based changing there. :-/

Is there any chance someone that can open it could possibly save it as compatible for an older version of Fusion 360? My version is 2.0.11680.

UPDATE:

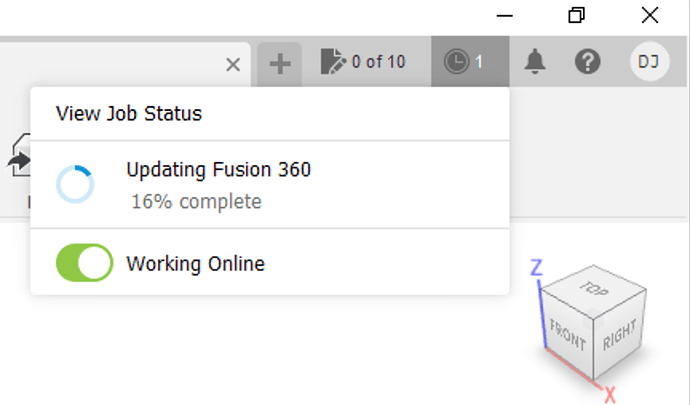

Possibly good news. I remembered I had a Windows version of F360 in a virtual machine of Windows 10, and I tried opening it there. That install is still too old, but it should be updatable, so I will wait for the update to complete and try again!

UPDATE - good and “gooder” and not quite as good:

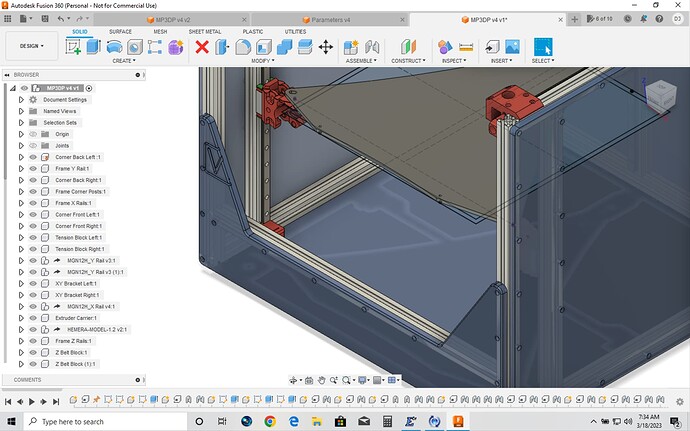

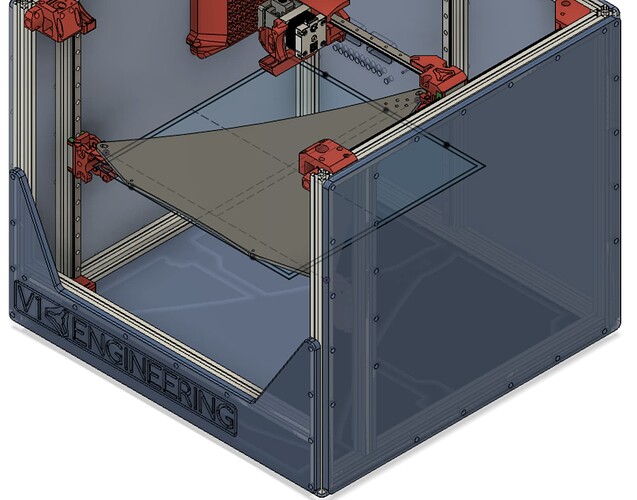

Good: OK, I was able to update F360, and I was able to open the params file and edit it (for now trying 325 x 325 x 325), and I was able to open the main file with the printer design.

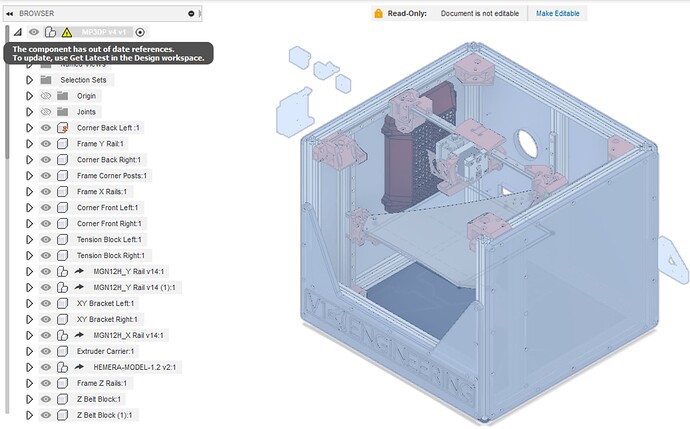

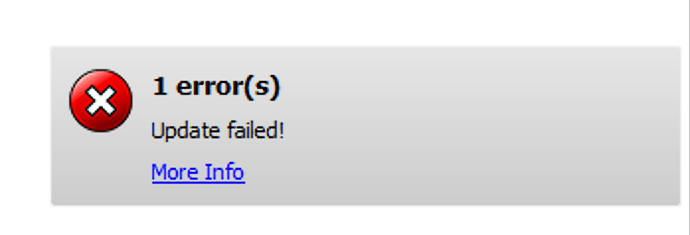

Gooder: It said I have one component that is “out of date” but I was able update. However, notice that this worked only after saving a copy of the main file, and reopening it. Until then, I got errors when trying to update the out of date component

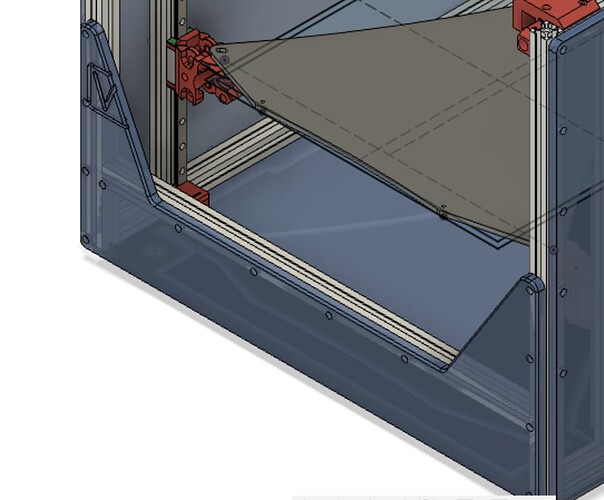

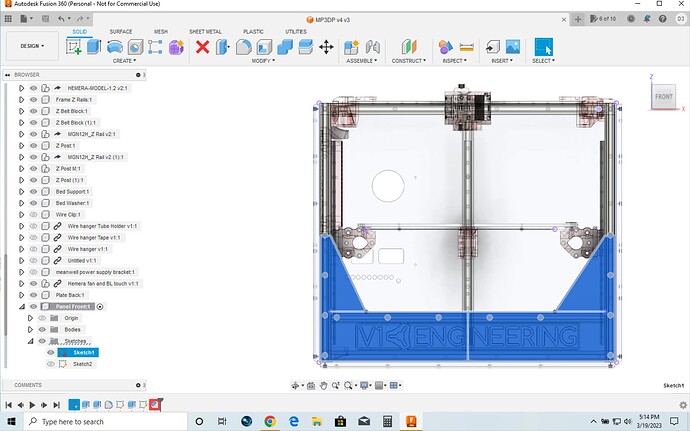

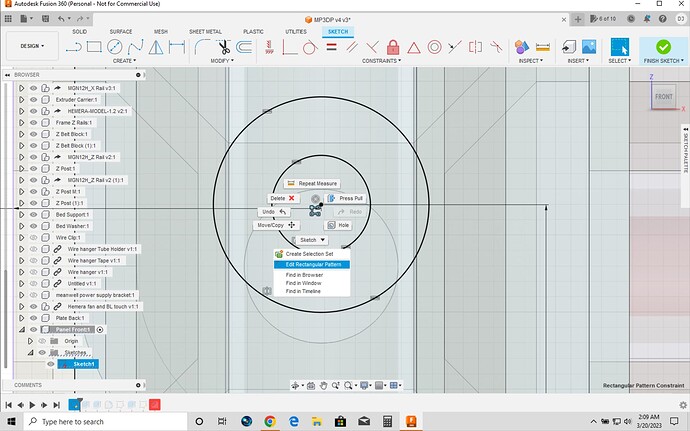

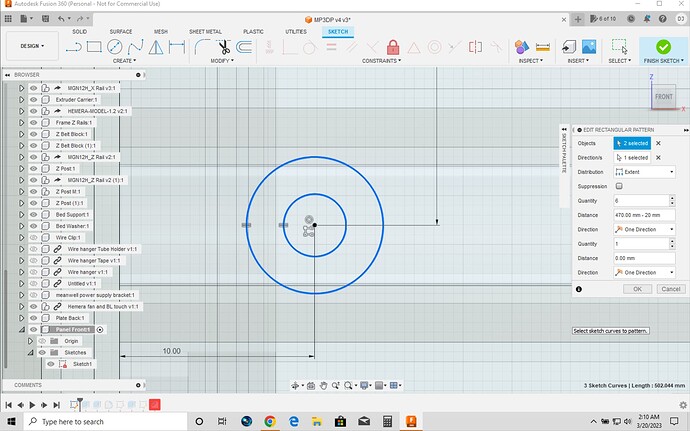

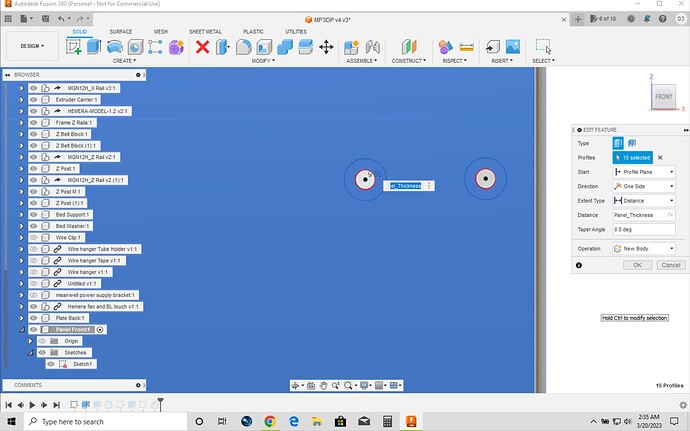

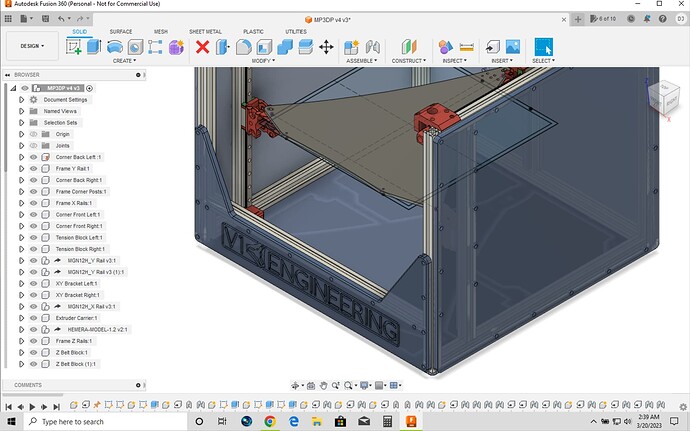

What it looked like before saving a copy of the main file, and reopening it:

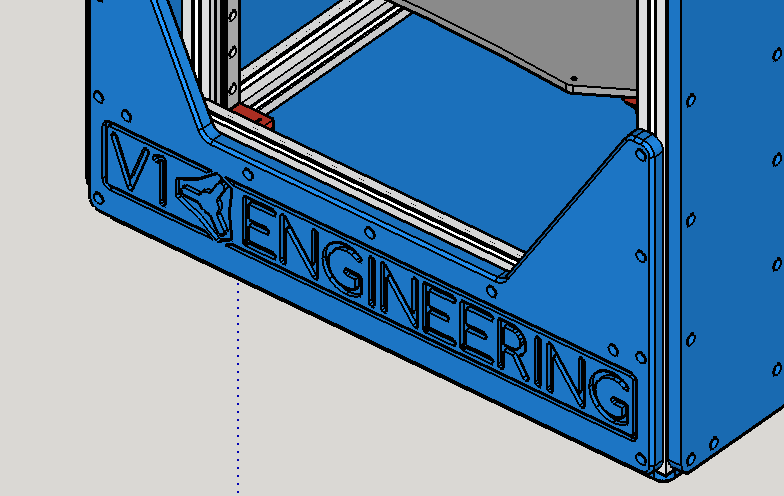

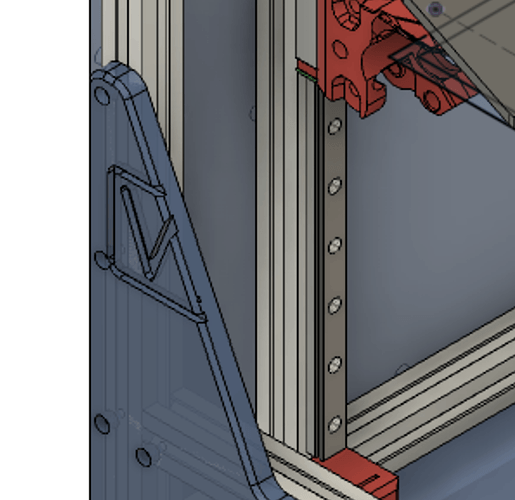

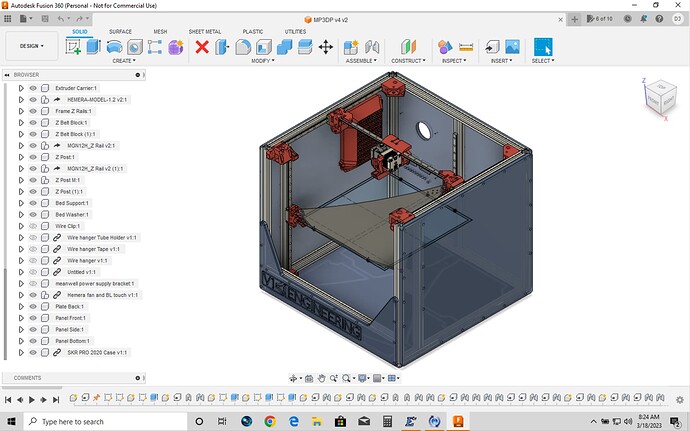

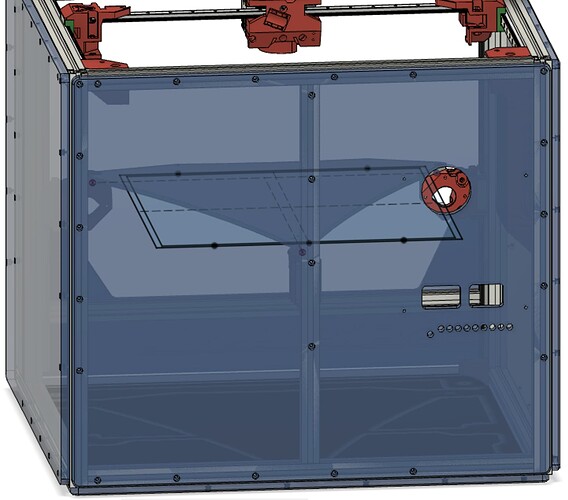

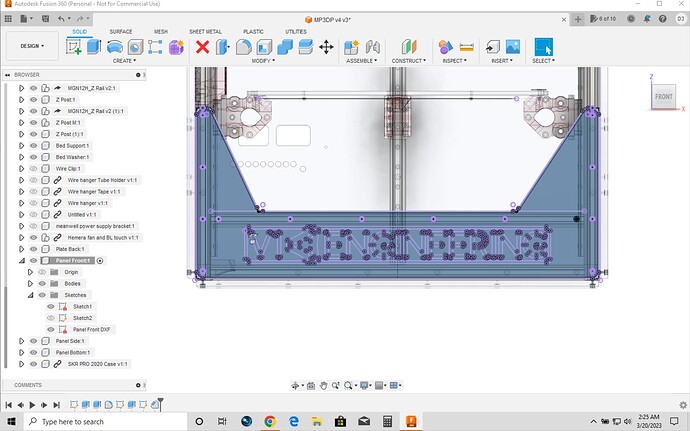

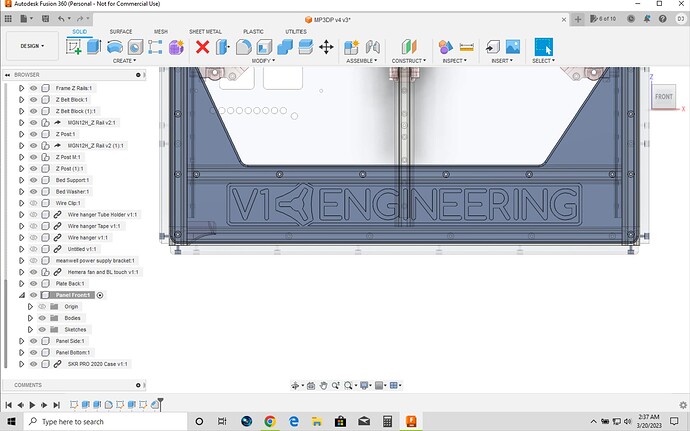

Not quite as good: The front enclosure panel, prior to editing params and updating the component, had a V1 Engineering logo cut in, across the bottom, but after the updates to params and component, the logo got raised up too high to work:

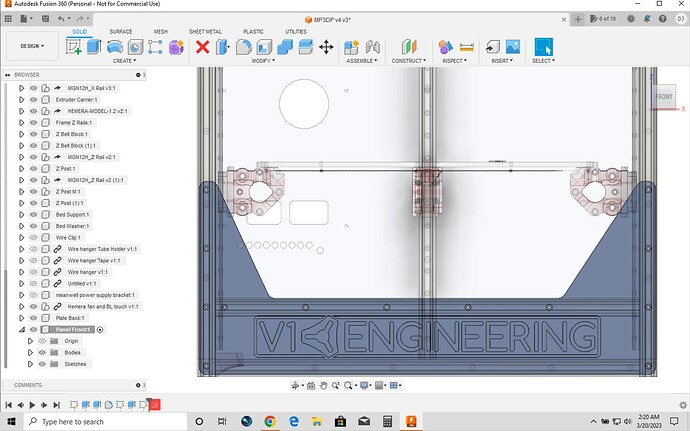

BEFORE editing params, saving, reopening, and updating the component (screen shot from SketchUp because I did not have any screen shot from Fusion from before):

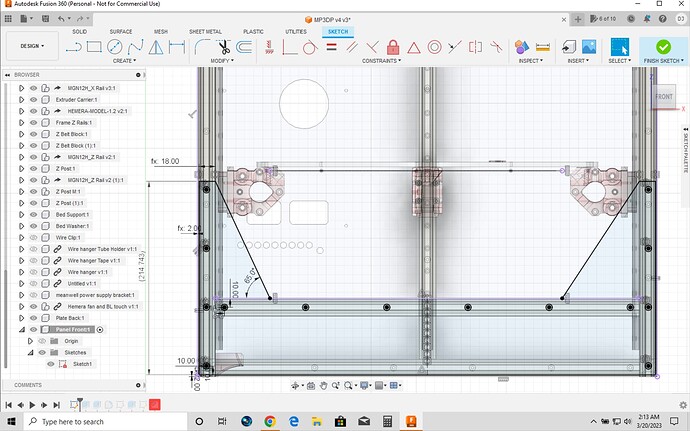

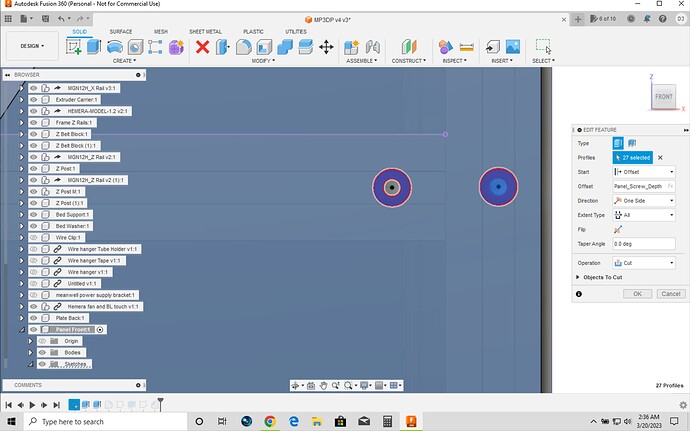

AFTER editing params, saving, reopening, and updating the component:

Update:

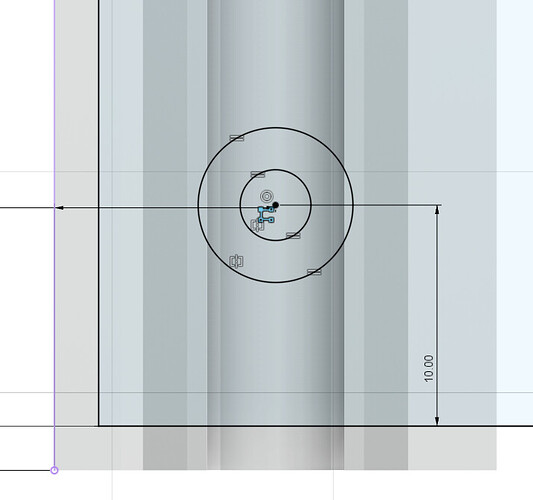

I manually moved the sketch that produces the V1E logo cut in, and it updated the cut in location to be better.

However, after later going through some details to get the X, Y, and Z linear rails to update to the length based on change to params ( as described in this post here: MP3DP v4 - Aza's build - #25 by DougJoseph ), the V1E logo placement when back to being out of place (I also note that I manually moved it, but did not add any constraints to its location):