“Is it the Rambo or your PLH3D board that is not performing as expected.”, That’s what I wanted to hear from you. The rambo on the multimeter shows 0.05V. Is this how it should be?

No. With M42, you should see:

M42 P45 S64 ; Should read around 1.25V M42 P45 S128 ; Should read around 2.5V M42 P45 S192 ; Should read around 3.75V M42 P45 S255 ; Should read around 5.0V M42 P45 S0 ; Should read around 0.0V

Your low voltage may indicate you don’t have things connected correctly, or it is remotely possible you burned out a pin. The Rambo has protection on most pins, so burning out a pin is unlikely.

I checked Rambo with your teams. Everything turned out OK. As you wrote above. The code matched the voltage. It turns out Rambo takes direct commands to him. But when I click on start to make a contour and the like, there are no changes on the multimeter. The power supply of the last command remains. For example, M42 P45 S192 - 3.75V or M42 P45 S0 - 0V

P.S. I am from Ukraine and I write through a translator, so there may be some misunderstandings in the correspondence.

Can you upload the g-code file you are using for your “contour”? You can save it from inside Lightburn and upload it using this icon.

![]()

Can you post the version number of the Marlin firmware you are using?

P.S. I am from Ukraine and I write through a translator, so there may be some misunderstandings in the correspondence.

It is pretty common for forum posts to go through a translator. Translators these days are pretty good, so we have little trouble figuring out the questions/information.

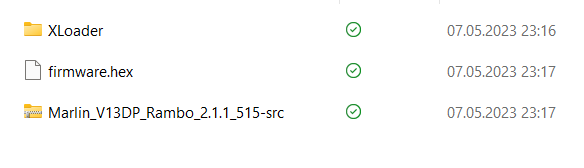

I bought the board on this site about 3 years ago. I updated it a few days ago. I took all the information for updating from this site.

Marlin_V13DP_Rambo_2.1.1_515-src through XLoader

; LB by SSG 1.2.01

; Marlin device profile, current position

; Bounds: X-84.77 Y-98.43 to X84.77 Y98.43

;USER START SCRIPT

M4

;USER START SCRIPT

G21

G91

; Cut @ 4000 mm/min, 100% power

M8

M05

G0 X-68.235 Y-7.426 F6000

; Layer C00

G1 Y51 F4000 I S255

G1 X145

G1 Y-51

G1 X-145

M05

G0 X20.842 Y-45.27 F6000

G1 X1.705 Y0.331 F4000 I S255

G1 X1.734 Y0.32

G1 X1.761 Y0.307

G1 X1.789 Y0.295

G1 X1.814 Y0.282

G1 X1.841 Y0.27

G1 X1.865 Y0.256

G1 X1.89 Y0.244

G1 X1.913 Y0.231

G1 X1.936 Y0.217

G1 X1.958 Y0.203

G1 X1.98 Y0.19

G1 X4.023 Y0.337

G1 X4.101 Y0.279

G1 X4.174 Y0.22

G1 X4.242 Y0.159

G1 X4.305 Y0.096

G1 X4.362 Y0.033

G1 X4.362 Y-0.033

G1 X4.305 Y-0.096

G1 X4.242 Y-0.159

G1 X4.174 Y-0.22

G1 X4.101 Y-0.279

G1 X4.023 Y-0.337

G1 X1.98 Y-0.19

G1 X1.958 Y-0.203

G1 X1.936 Y-0.217

G1 X1.913 Y-0.231

G1 X1.89 Y-0.244

G1 X1.865 Y-0.256

G1 X1.841 Y-0.27

G1 X1.814 Y-0.282

G1 X1.789 Y-0.295

G1 X1.761 Y-0.307

G1 X1.734 Y-0.32

G1 X1.705 Y-0.331

G1 X1.677 Y-0.342

G1 X1.646 Y-0.355

G1 X1.617 Y-0.365

G1 X1.586 Y-0.377

G1 X1.554 Y-0.387

G1 X1.521 Y-0.399

G1 X1.489 Y-0.408

G1 X1.455 Y-0.419

G1 X1.421 Y-0.43

G1 X1.386 Y-0.439

G1 X1.35 Y-0.448

G1 X1.314 Y-0.459

G1 X1.277 Y-0.467

G1 X1.239 Y-0.477

G1 X1.202 Y-0.486

G1 X1.162 Y-0.494

G1 X1.122 Y-0.503

G1 X1.083 Y-0.512

G1 X1.041 Y-0.519

G1 X1 Y-0.528

G1 X0.957 Y-0.535

G1 X0.915 Y-0.543

G1 X0.87 Y-0.55

G1 X0.827 Y-0.557

G1 X0.782 Y-0.564

G1 X0.736 Y-0.571

G1 X0.69 Y-0.578

G1 X0.642 Y-0.584

G1 X0.596 Y-0.59

G1 X0.547 Y-0.596

G1 X0.498 Y-0.602

G1 X0.448 Y-0.608

G1 X0.398 Y-0.613

G1 X0.348 Y-0.618

G1 X0.295 Y-0.623

G1 X0.244 Y-0.628

G1 X0.19 Y-0.633

G1 X0.137 Y-0.637

G1 X0.083 Y-0.641

G1 X0.027 Y-0.645

G1 X-0.027 Y-0.645

G1 X-0.083 Y-0.642

G1 X-0.137 Y-0.637

G1 X-0.19 Y-0.632

G1 X-0.244 Y-0.628

G1 X-0.295 Y-0.623

G1 X-0.348 Y-0.619

G1 X-0.398 Y-0.612

G1 X-0.448 Y-0.608

G1 X-0.498 Y-0.602

G1 X-0.547 Y-0.596

G1 X-0.596 Y-0.59

G1 X-0.642 Y-0.584

G1 X-0.69 Y-0.578

G1 X-0.736 Y-0.571

G1 X-0.782 Y-0.564

G1 X-0.827 Y-0.558

G1 X-0.87 Y-0.55

G1 X-0.915 Y-0.542

G1 X-0.957 Y-0.536

G1 X-1 Y-0.527

G1 X-1.041 Y-0.52

G1 X-1.083 Y-0.511

G1 X-1.122 Y-0.503

G1 X-1.162 Y-0.494

G1 X-1.202 Y-0.486

G1 X-1.239 Y-0.477

G1 X-1.277 Y-0.467

G1 X-1.314 Y-0.459

G1 X-1.35 Y-0.449

G1 X-1.386 Y-0.439

G1 X-1.421 Y-0.429

G1 X-1.455 Y-0.419

G1 X-1.489 Y-0.409

G1 X-1.521 Y-0.398

G1 X-1.554 Y-0.387

G1 X-1.586 Y-0.377

G1 X-1.617 Y-0.365

G1 X-1.646 Y-0.355

G1 X-1.677 Y-0.342

G1 X-1.705 Y-0.332

G1 X-1.734 Y-0.319

G1 X-1.761 Y-0.307

G1 X-1.789 Y-0.295

G1 X-1.814 Y-0.282

G1 X-1.841 Y-0.27

G1 X-1.865 Y-0.257

G1 X-1.89 Y-0.243

G1 X-1.913 Y-0.231

G1 X-1.936 Y-0.217

G1 X-1.958 Y-0.204

G1 X-1.98 Y-0.189

G1 X-4.023 Y-0.337

G1 X-4.101 Y-0.279

G1 X-4.174 Y-0.22

G1 X-4.242 Y-0.159

G1 X-4.305 Y-0.097

G1 X-4.362 Y-0.032

G1 X-4.362 Y0.032

G1 X-4.305 Y0.097

G1 X-4.242 Y0.159

G1 X-4.174 Y0.22

G1 X-4.101 Y0.279

G1 X-4.023 Y0.337

G1 X-1.98 Y0.189

G1 X-1.958 Y0.204

G1 X-1.936 Y0.217

G1 X-1.913 Y0.231

G1 X-1.89 Y0.243

G1 X-1.865 Y0.257

G1 X-1.841 Y0.27

G1 X-1.814 Y0.282

G1 X-1.789 Y0.295

G1 X-1.761 Y0.307

G1 X-1.734 Y0.319

G1 X-1.705 Y0.332

G1 X-1.677 Y0.342

G1 X-1.646 Y0.355

G1 X-1.617 Y0.365

G1 X-1.586 Y0.377

G1 X-1.554 Y0.387

G1 X-1.521 Y0.398

G1 X-1.489 Y0.409

G1 X-1.455 Y0.419

G1 X-1.421 Y0.429

G1 X-1.386 Y0.439

G1 X-1.35 Y0.449

G1 X-1.314 Y0.459

G1 X-1.277 Y0.467

G1 X-1.239 Y0.477

G1 X-1.202 Y0.486

G1 X-1.162 Y0.494

G1 X-1.122 Y0.503

G1 X-1.083 Y0.511

G1 X-1.041 Y0.52

G1 X-1 Y0.527

G1 X-0.957 Y0.536

G1 X-0.915 Y0.542

G1 X-0.87 Y0.55

G1 X-0.827 Y0.558

G1 X-0.782 Y0.564

G1 X-0.736 Y0.571

G1 X-0.69 Y0.578

G1 X-0.642 Y0.584

G1 X-0.596 Y0.59

G1 X-0.547 Y0.596

G1 X-0.498 Y0.602

G1 X-0.448 Y0.608

G1 X-0.398 Y0.612

G1 X-0.348 Y0.619

G1 X-0.295 Y0.623

G1 X-0.244 Y0.628

G1 X-0.19 Y0.632

G1 X-0.137 Y0.637

G1 X-0.083 Y0.642

G1 X-0.027 Y0.645

G1 X0.027 Y0.645

G1 X0.083 Y0.641

G1 X0.137 Y0.637

G1 X0.19 Y0.633

G1 X0.244 Y0.628

G1 X0.295 Y0.623

G1 X0.348 Y0.618

G1 X0.398 Y0.613

G1 X0.448 Y0.608

G1 X0.498 Y0.602

G1 X0.547 Y0.596

G1 X0.596 Y0.59

G1 X0.642 Y0.584

G1 X0.69 Y0.578

G1 X0.736 Y0.571

G1 X0.782 Y0.564

G1 X0.827 Y0.557

G1 X0.87 Y0.55

G1 X0.915 Y0.543

G1 X0.957 Y0.535

G1 X1 Y0.528

G1 X1.041 Y0.519

G1 X1.083 Y0.512

G1 X1.122 Y0.503

G1 X1.162 Y0.494

G1 X1.202 Y0.486

G1 X1.239 Y0.477

G1 X1.277 Y0.467

G1 X1.314 Y0.459

G1 X1.35 Y0.448

G1 X1.386 Y0.439

G1 X1.421 Y0.43

G1 X1.455 Y0.419

G1 X1.489 Y0.408

G1 X1.521 Y0.399

G1 X1.554 Y0.387

G1 X1.586 Y0.377

G1 X1.617 Y0.365

G1 X1.646 Y0.355

G1 X1.677 Y0.342

M05

G0 X19.868 Y112.744 F6000

G1 X-29.677 Y19.189 F4000 I S255

G1 X29.677 Y19.189

G1 X59.354

G1 X29.677 Y-19.189

G1 X-29.677 Y-19.189

G1 X-59.354

M9

M05

; return to starting pos

G0 X27.525 Y-60.048 F6000

;USER END SCRIPT

M5

;USER END SCRIPT

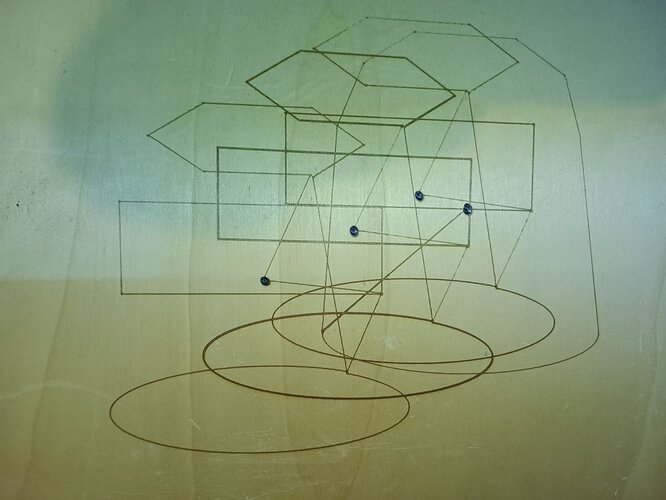

I just did another experiment. PWM + grounding left as is. But I added grounding to Enable #1 Input and sent 5 volts to ANGIN 5V INPUT. The laser is switched on at a constant unknown power. Even if you set the power to 10%, at least 100%, there is no difference. When you turn it on and don’t press the start button, it burns out the point of its position. During the transition from one shape to the processing of another, it does not reset the power and leaves a trace. The photo shows the work of the Gcode that I put up above.

There is one problem. Your start code should be:

M3 I

And remove the M4 from your start code.

The M3 I enables inline commands, and your code has inline commands like this one:

G1 Y51 F4000 I S255

Note, you should be able to test your laser with just M42. With the laser connected, send a S1 to turn the laser on at very low power. Try different values. S255 will be full power. You should also verify by looking at the screen or by sending a M115 that the new firmware made it to your board.

What should be the transfer rate? 250000?

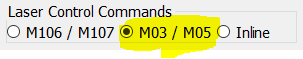

I tried both M3 and M4, there is no difference. I left the M4 as the laser manufacturer advises. Above there is a photo of the start window that the manufacturer advises to put.The manufacturer has its own G code generator. I can’t find how to import a ready-made Gcode file to LightBurn? Only photo formats, DXF and the like.

The ‘I’ in M3 I is very important. Without it, inline commands are not processed by Marlin.

Can you control the laser intensity with the M42 commands as I suggested in my previous post?

The transfer rate for Marlin is 250000.

Yes. But nothing changes after the start. The power of the last command remains. For example: M42 P45 S0, then it will process with this power. Please reply to my last post.

To the best of my knowledge, you cannot import g-code into Lightburn. You can import DXF, SVG, or images like JPG and PNG. Basically, you can import vector formats and images. You can put g-code in the start code and end code sections in Lightburn, but I believe you are already doing that.

I want to be very clear since there is a potential translation issue. Using M42, you are able to control the intensity of the laser beam. Correct? If so, then your laser itself is set up correctly, and we are looking for other issues.

I also want to be very clear, you put this exact line in your start code. Correct?

M3 I

If you want to try something else, you can change Lightburn so that it is outputting M3/M5 commands instead of inline commands:

You really want Inline to work, so this is just a debugging step so you can figure out what is going wrong.

When I updated it, I used the instructions taken from this site. The Loader program does not have the ability to set a transfer rate of 250000, could this be a problem?

No. The transfer rate of 250000 applies to communication with Marlin. The transfer rate of XLoader 115200.

So, the things I asked about that you have not answered:

-

Verification through either M115 or the display that the correct firmware is on the board. You showed me the files, but you did not confirm that the files made it to the control board.

-

Verification that the laser is adjusting its power with different M42 settings

-

Verification that M3 I is added in the start code and is in the top of your g-code file. You can upload your g-code file for me to verify. Note you can upload the g-code file as an attachment. You don’t need to post the file.

-

Results of changing to M3/M5 in Lightburn.

M115

FIRMWARE_NAME:Marlin 515P 2.1.1 (Sep 25 2022 17:42:50) SOURCE_CODE_URL:github.com/MarlinFirmware/Marlin PROTOCOL_VERSION:1.0 MACHINE_TYPE:V1 3DP 515P EXTRUDER_COUNT:1 UUID:cede2a2f-41a2-4748-9b12-c55c62f367ff

Cap:SERIAL_XON_XOFF:0

Cap:BINARY_FILE_TRANSFER:0

Cap:EEPROM:1

Cap:VOLUMETRIC:1

Cap:AUTOREPORT_POS:0

Cap:AUTOREPORT_TEMP:1

Cap:PROGRESS:0

Cap:PRINT_JOB:1

Cap:AUTOLEVEL:0

Cap:RUNOUT:0

Cap:Z_PROBE:0

Cap:LEVELING_DATA:0

Cap:BUILD_PERCENT:0

Cap:SOFTWARE_POWER:0

Cap:TOGGLE_LIGHTS:0

Cap:CASE_LIGHT_BRIGHTNESS:0

Cap:EMERGENCY_PARSER:0

Cap:HOST_ACTION_COMMANDS:0

Cap:PROMPT_SUPPORT:0

Cap:SDCARD:1

Cap:MULTI_VOLUME:0

Cap:REPEAT:0

Cap:SD_WRITE:1

Cap:AUTOREPORT_SD_STATUS:0

Cap:LONG_FILENAME:0

Cap:LFN_WRITE:0

Cap:CUSTOM_FIRMWARE_UPLOAD:0

Cap:EXTENDED_M20:0

Cap:THERMAL_PROTECTION:1

Cap:MOTION_MODES:1

Cap:ARCS:1

Cap:BABYSTEPPING:0

Cap:CHAMBER_TEMPERATURE:0

Cap:COOLER_TEMPER

ATURE:0

Cap:MEATPACK:0

Cap:CONFIG_EXPORT:0

I can’t make attachments to a new user.

the laser does not turn on.

the laser does not turn on.

Yes, it reacts. When the adapter is first started, the laser does not turn on. If you send the command M42 P45 S1, it turns on and stays with this command in the future. That is, if I click on the start of engraving of any figure, it will engrave it with the power that I gave in advance with the M42 command and does not respond to the settings that I set for engraving, for example, 20%. If I give the command M42 P45 S250, the laser engraves the same figure with this power and does not respond by 20%. The same thing happens with M3 I and M3/M5

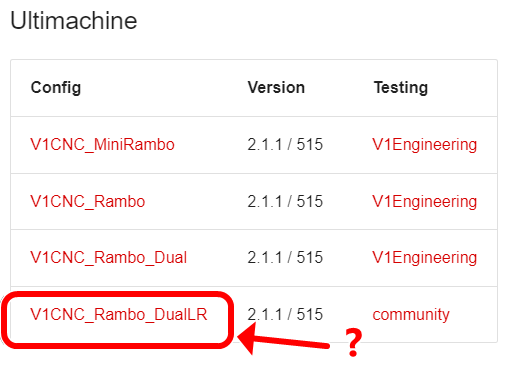

I figured out the problem, and I’m sorry I did not catch it sooner. You installed the firmware for the V1 3D printer, not the Lowrider. From this page, you want to download V1CNC_Rambo_DualLR. Note the LR in the title indicating it is the firmware for the Lowrider. Use XLoader to update the firmware, and then retest. If you have the M3 I at the beginning of the file, and if you have Lightburn set for Inline commands, then your laser should work.

Thanks! Are you talking about this firmware that’s in the photo?

Rewired. At M3/M5, the laser does not turn on. At M3 I turns on but there are no traces on the board. With the M4 code, it turned out that in the photo. Only mirrored. How to fix it. Somewhere in LightBurn?

“You can use extruder 1 fan or other MOSFET output. Then use inverted TTL input on our PLH3D CNC Adapter.”

I got this information on Facebook from the manufacturer. But I haven’t experienced it yet.