The first Acrylic cut and Cutting Polycarbonate topics have been very helpful in figuring out trochoidal settings.

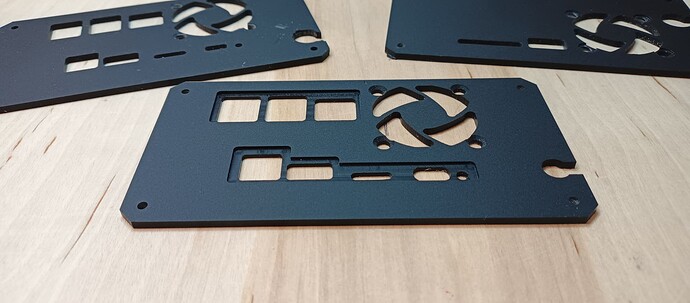

Only used 1/8" single flute upcut carbide bit from V1E to drill, taper/chamfer drill holes, pocket, hole and contour cut part from 3mm Matte acrylic panel. Fusion 360 → DXF → EstlCam.

Cheers!