I’m still having fun with this project, working in the weekdays after dinner.

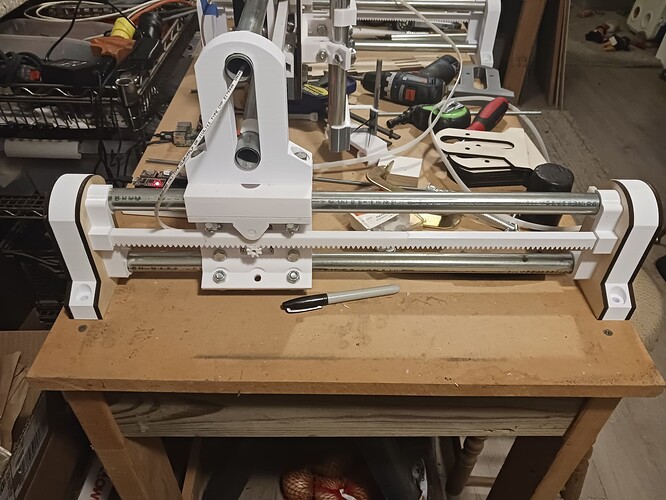

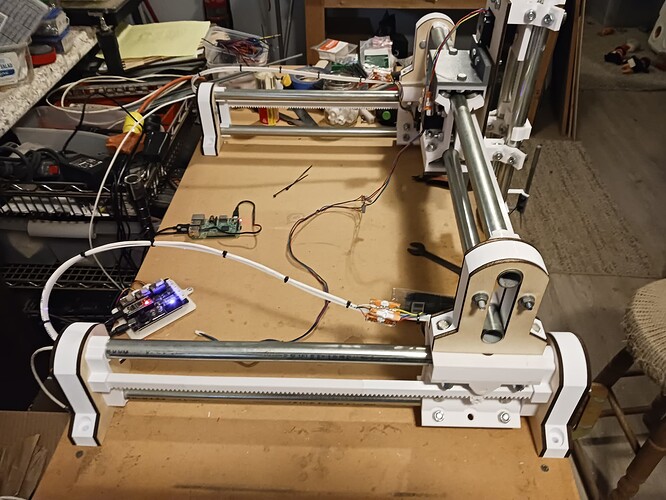

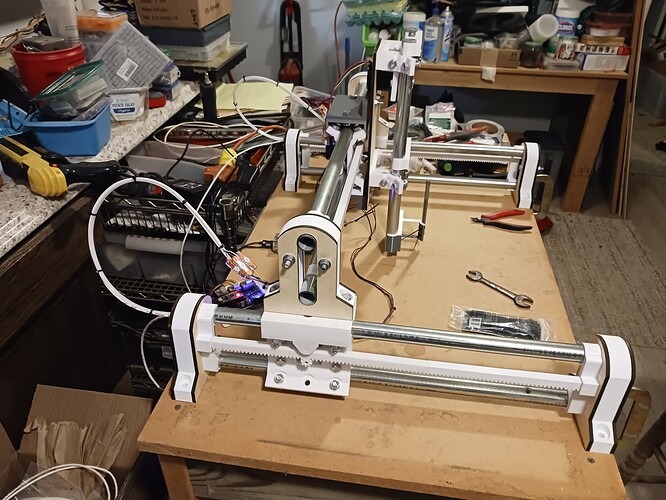

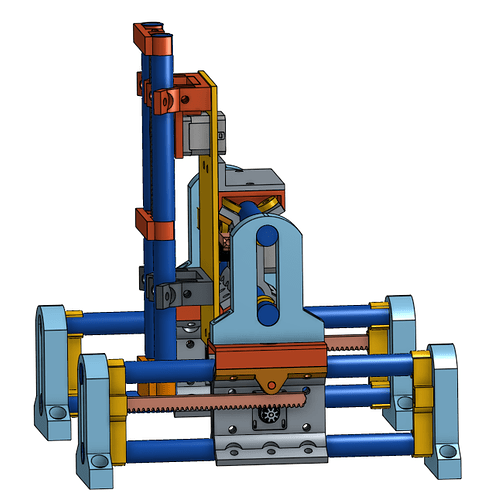

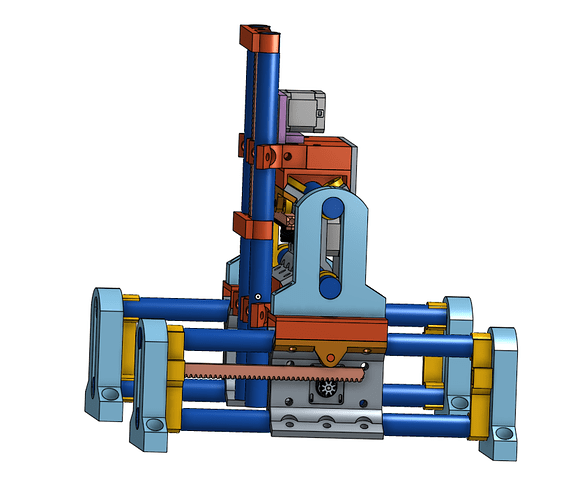

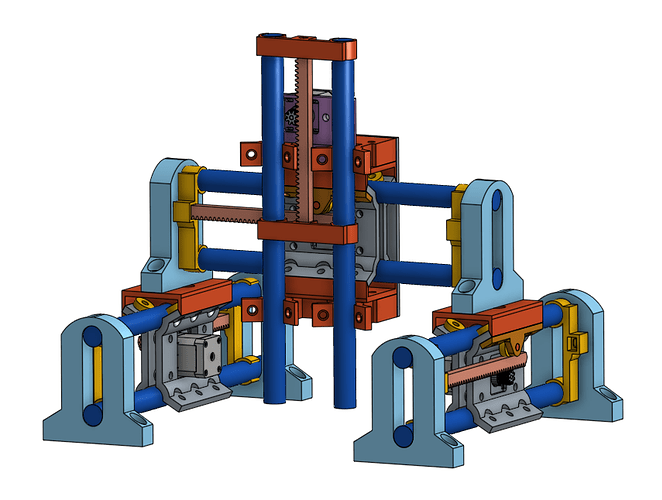

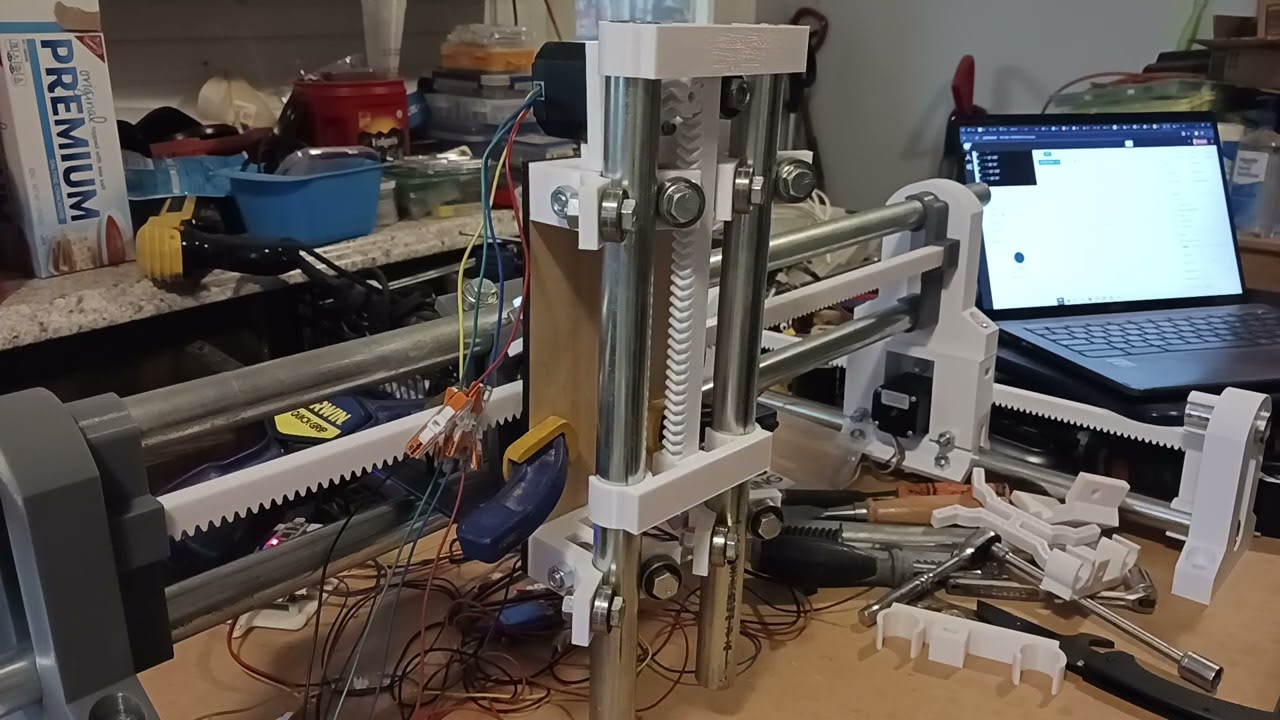

You can just make out on the right side of the picture below a mock-up I did this evening. I don’t think I’ll build Y this long (qty 5 each of the 40 tooth rack segments.).

Since I’m using EMT left from the dissasembly of my LR3 project, I have lengths of tubing sufficient to test this. The mockup is sitting on one of the “Lift plates” I made for my LR4 beta build table, because it was sitting in a corner not presently in use in the LR4 table.

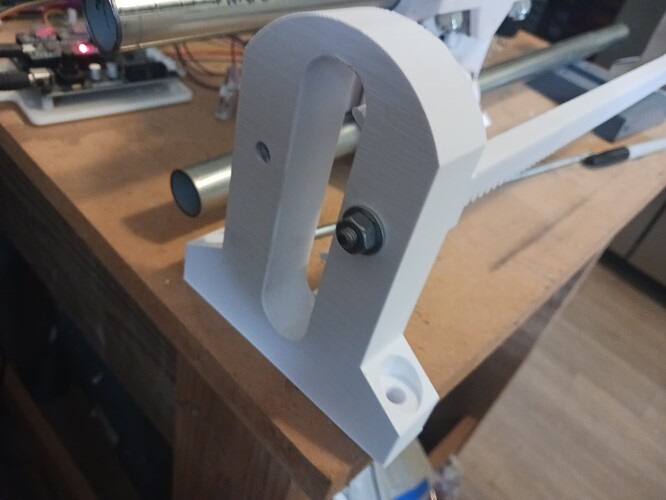

I’ve printed some caps, here I’m using a couple of red caps. I decided that with a washer under the hole i drilled in the carriage ends, it would look fine. I then looked at the red caps on the printers and said “why not see how it looks.” So there’s a v1 color theme mockup, minus the DKJ white center parts.

The 1/4-20 rod and coupler nuts were sitting in a storage closet in the garage. The rods will get cut down and I’ll find some Nyloc nuts at some point but for mockup work it’s fine.

I think it looks great in V1 colors!

Collecting a few caps to play with color schemes maybe later when I build up the XY portion.

I do have a few things I’m debating. I mentioned above that I’d considered again whether to stick with leftover old LulzBot parts, or do something with a higher torque stepper motor.

Well, I’m still debating. This arrived from China. Closed loop stepper controllers. I was going to outfit X and Y on a LR4 with these, and I bought some spares. Not sure which way I’ll go.

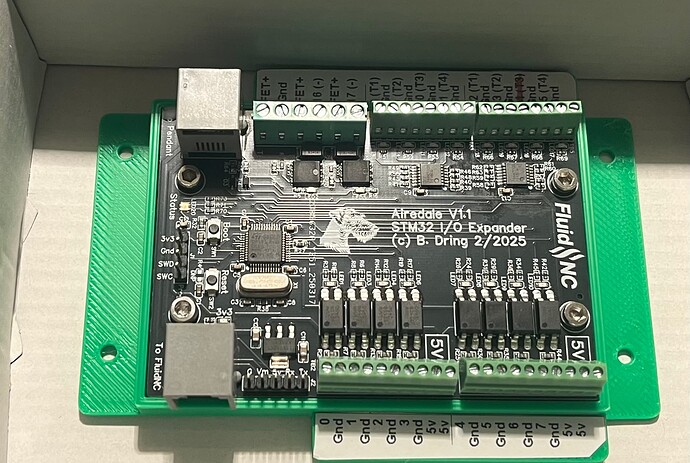

I’m also still thinking of having modular, interchangable controllers. One thing experimental that will go in this build is an…

Airdale.

It is an STM-32 FluidNC UART-based IO expander. What does that do? It lets you attach multiple UART peripherals (Like a FluidDial pendant or a CYD), but also adds multiple additional IO channels to an existing FluidNC system.

This is going to go on one of my spare Jackpot boards for experimentation. A jackpot with one of these could support LOTS of additional IO that isn’t really suited to the existing IO coming off of an ESP-32.

The Airdale has a cousin that should be coming as well, it’s a slightly different breed. If it works like I think it will, it will probably sway my decision about whether or not to use closed loop steppers.

Some notes for myself:

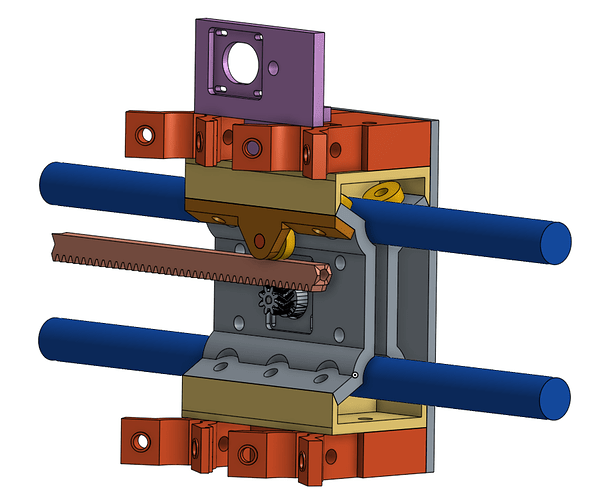

I have printed 40 and 20 tooth rack. If a 10 tooth rack were part of the file set, then one could do an arbitrary length of rack from 10 tooth up in incrments of 10 tooth at a go.

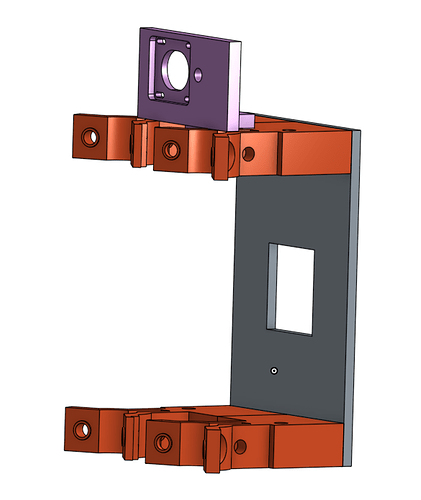

I continue to be impressed at the more reasonable sizes with the stoutness of these printed axis skeletons.

I had some fiddling to do to get the “non-pointy” side of the printed rack to fit the rough (supports side) of the clip. Mostly an assembly knowledge limitation on my part.

Edit: one other thing I thought about: If one were to get really silly and stack long lengths of the printed rack together, a variant of the clip that could help keep the rack from bowing out would be darned useful. I’m putting that back in the thinking step for now.