Once again I feel a bit embarrassed that I procrastinate the way I do… I could have accomplished what I’m about to share a couple of weeks ago. But I guess it’s as they say, better later than never…

I stumbled across – not sure how I missed it for so long (too caught up in lasers at the time, I guess!) – the CNC drag races that Ryan instigated some several years ago. What a great read. It’s truly impressive what has been accomplished since… 16 minute runs that eventually plummeted all the way down to under 40 seconds. Ryan, Philipp, Doug, and others put out some spectacular YT videos showing their results… and Jamie concocted a super interesting “hog-out” method to measure progress toward taking maximal cuts in a material with your machines.

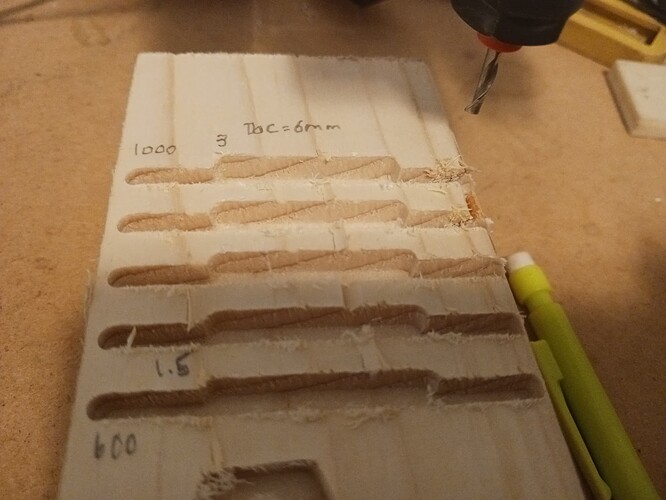

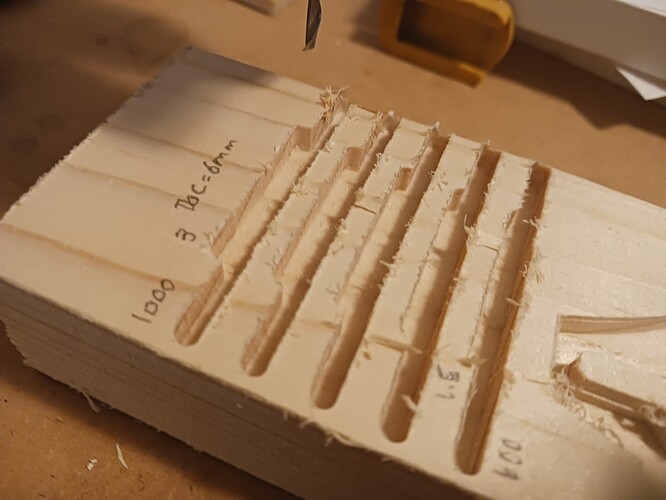

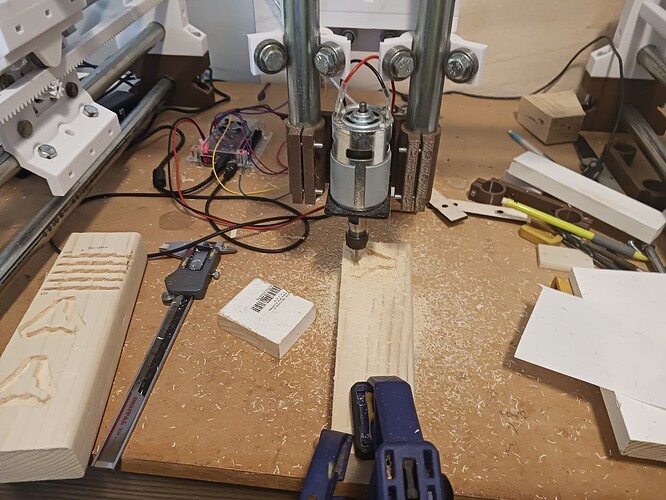

Well, I’m not gonna challenge any of those times but do want to report that I’ve actually patterned some of my MPR&P testing after what I saw there. Starting with Jamie’s hog-out pattern, I’ve subjected MPR&P and the small 775 “spindle” mounted to it to far more strenuous tests than I ever thought possible… and possibly even more than the 6mm DOC and 1000 mm/min in pine that I’ll report here. Initially thinking the 775 “spindle” little more than a toy, I’ve about changed my tune… and now think it’s actually a worthwhile accessory for the MPR&P (given you don’t have a LR4).

Finally, about those V1 logo’s in that last photo… these are quarter-sized copies (XYZ dimensions scaled by 0.5) of Ryan’s drag race logo in white(?) pine. My latest modest attempt is a simple roughing cut at 6mm full-depth in 1:28 minutes. It’s not nearly so clean as the cut would be in MDF but I’m using scraps of wood that I have on hand.

The depth and diagonals are just about right for the 50% scale I’ve used…

While certainly not pretty or perfect, I’m thoroughly pleased with these results. As I said, I really thought the 775 “spindle” was more a toy, as it is most usually seen on the tiny 1610 and 3018 desktop CNC’s that are so widely available. I’ve got a couple of those but had never done anything more than scratch/engrave a cartoon image on a piece of scrap wood before quickly converting them into a pen-plotter or laser-engraver.

I have several of the 775 motors and the first (unmarked) one I mounted on MPR&P was a lower-RPM motor… probably 8000-10000 rpm or so. It was responsible for the lower logo in the “hog-out” photo above. But a different one was substantially higher-RPM (they can be had up to 20000 RPM) and, for these hog-out tests, it only makes sense that a higher-RPM spindle will allow for a faster feed. It is responsible for the far cleaner upper-most logo in the hog-out photo. Both of those logos were only 2mm deep, however… and the same gcode used for both.

Obviously, I’m a beginner here and my results with a tiny spindle are modest at best… certainly not to be compared with the powerful spindles and routers used in Ryan’s drag races. But this is for MPR&P testing and I am finding it fun (as did the drag racers!) pushing things a bit. Thankfully, I don’t think MPR&P is the limiting factor here – yet – so am looking forward to seeing what more it’ll do. As Jamie says in his “hog-out” blurb,

I hope this all makes sense…

– David