i cant find 1/8 ply anywhere! i’m sitting here trying to get my 1.6W laser to cut through 1/4" and hating every minute of it LOL

Amazon is your friend.

I did buy some from Amazon, but my laser won’t cut it

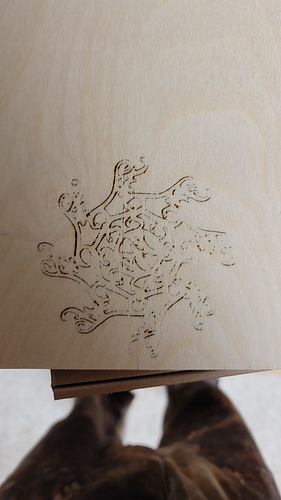

That is 10 passes at .3 mm and 50mm/s

This is the back

50mm/sec is pretty fast… I just realized I was posting my speeds in mm/sec instead of mm/min!  I just went and made the edit notations. Sorry if this was causing headaches!

I just went and made the edit notations. Sorry if this was causing headaches!  Try slower!

Try slower!

HAHAHHA… I am just now setting up my test file. I was looking at the fact that I typically burn at 10mm/sec and I was like, “How the heck is he burning THROUGH plywood at 100mm/sec”.

So, 100mm/min is ~1.6mm/sec.

What is the .3mm?

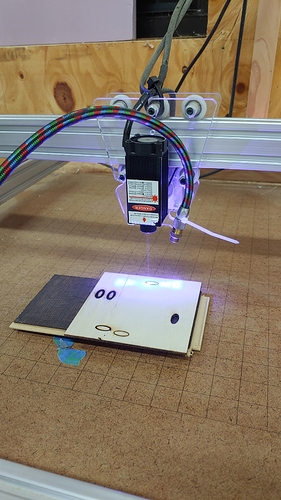

Thanks to your inspiration, I successfully burned a hole in a piece of plywood. I just did test circles. My significantly less powerful laser took quite a few more passes.

I ran at 2mm/min, 100% power, and 9 passes. I also rigged up a small air blaster using an air brush hose and the tip off of a blow gun. I ran it at about 18psi.

Nice! Hey, waitaminute, where you get that…(checks laser rig in next room). That hose looks familiar.

.3mm doc per pass,

Ahh, OK. From what I have found, and reading some other threads around here, you will get better results without dropping the Z every pass. This will also help lessen the wider burn on the top surface. Since the beam is essentially a inverted cone, focused on the material, every time you lower the Z, a wider part of the cone is hitting the top of the work. By looking at the bottom you were almost there! I would slow the movement down too.

Sorry I was mistaken that was at 50mm/min and I don’t think it will cut if I don’t drop the z down, I mean it will cut through the first 1mm but then the laser will be to unfocused to cut the rest of the way through. What is frustrating is I have cut through 3mm plywood before. At speeds of 140mm/min 6 passes and a doc of .5mm so I’m not sure if what is going on

I’ve noticed my penetration varies from piece to piece, even from the same bundle of sheets. I’m guessing its the glue thickness between the layers and/or the density of the layers.

I got it from the table behind me where my son and I were air brushing a model airplane

Looks like I have some more testing/changing to do to get really good cuts.

I went to cut an ornament and it didn’t go well. None of the cuts went all the way through and having to do 9 passes caused a lot of burning along the edges.

I took this as a sign that it is time to upgrade the laser on the machine. I’ve never been really happy with the 3.3w unit. I know a diode laser will never be as fast as a co2, but I always wanted it to etch just a little faster. We’ll see how it does with a more powerful unit.

I should probably make my own thread at this point.

there are some good black friday deals on aliexpress

That’s a great deal! Will this work with our MPCNCs though?

Well, why not?

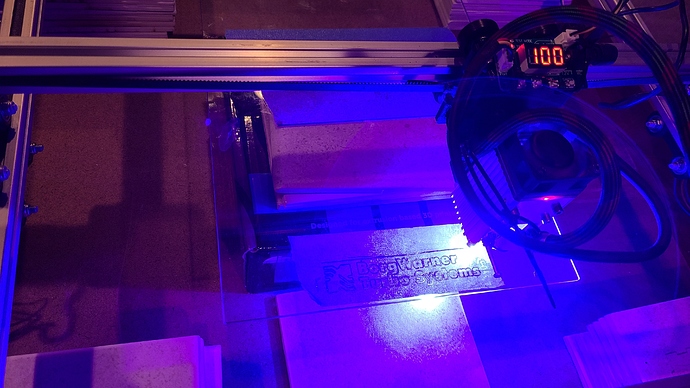

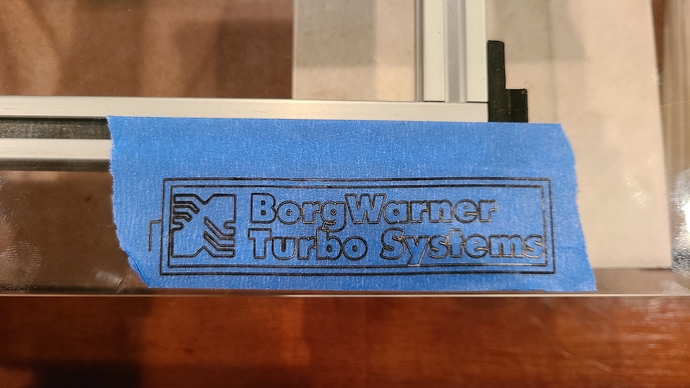

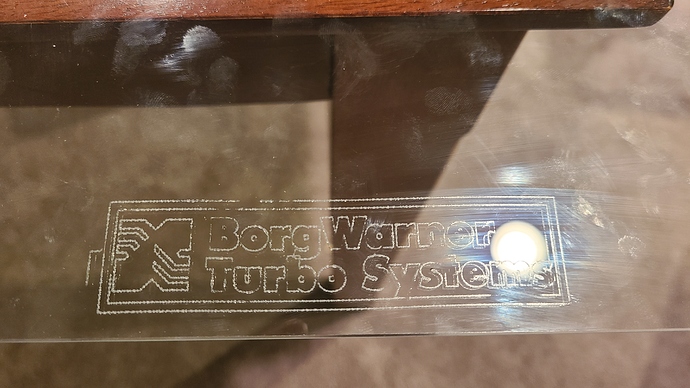

Glass is from a flat bed scanner I harvested for parts. 100mm/min, 100% on the frickin’ laser beam, single pass. Did make crackling noises as it burned. I didn’t know if it would shatter or not. Guess not.

It’s the little spots of glass spalling off the surface you hear. The under side of the tape will have glitter on it now.