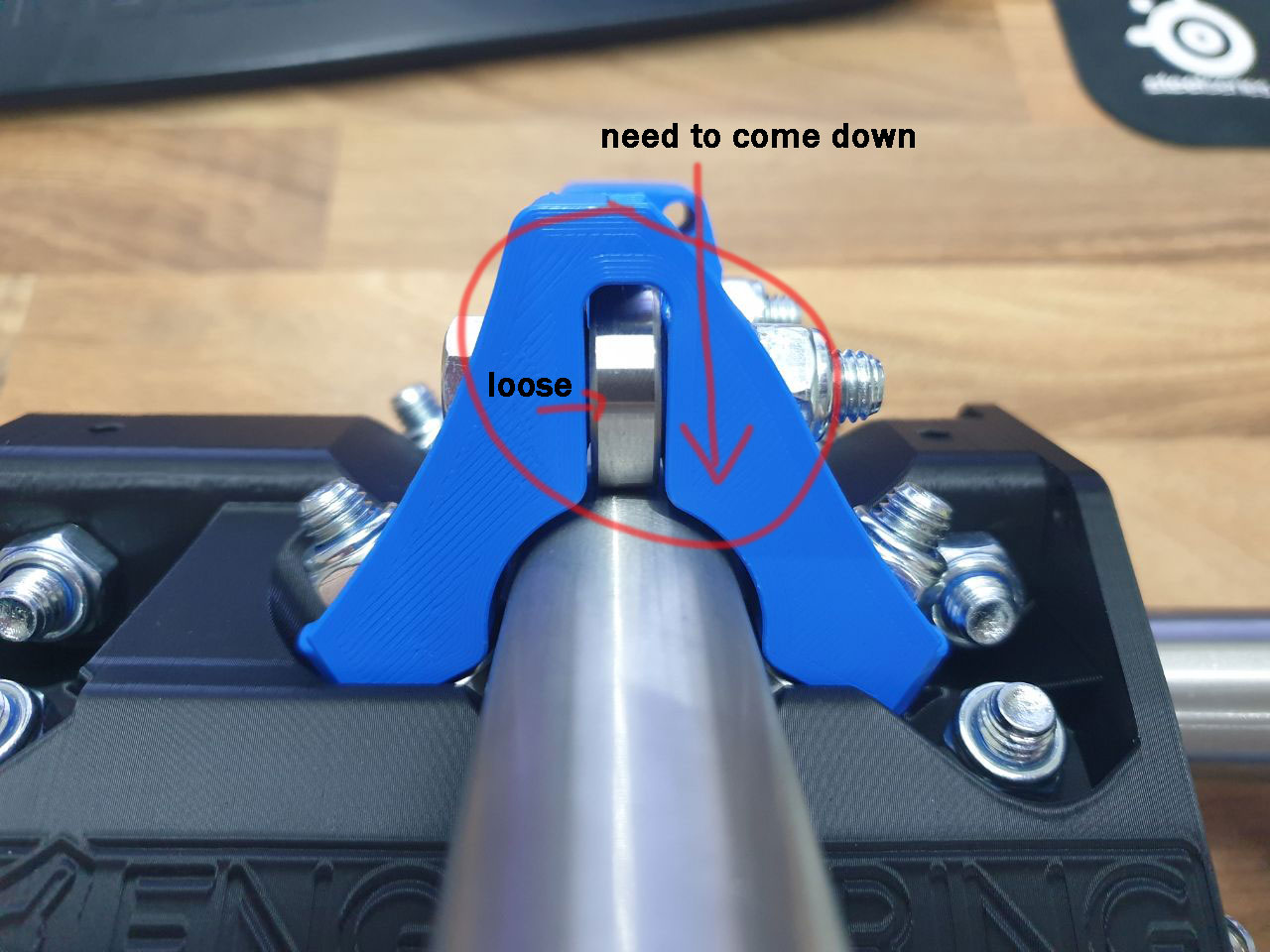

Hey, i just finished printing my parts and started assambling. My is wiggling too but only a bit. All other parts were perfect fitting.

Tightened the bolts very much make it better but endet in a little crack in a clamp. (not much a problem i make a new quickly) but thats not the solution.

i read sanding the clamp. i try that tomorrow.